Novel technology of two-effect evaporation of phosphoric acid with wet method

A technology of wet-process phosphoric acid and efficient evaporation, which is applied in the fields of phosphorus compounds, chemical instruments and methods, and inorganic chemistry. Effect of steam consumption, improvement of enterprise economic benefits, saving of construction materials and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

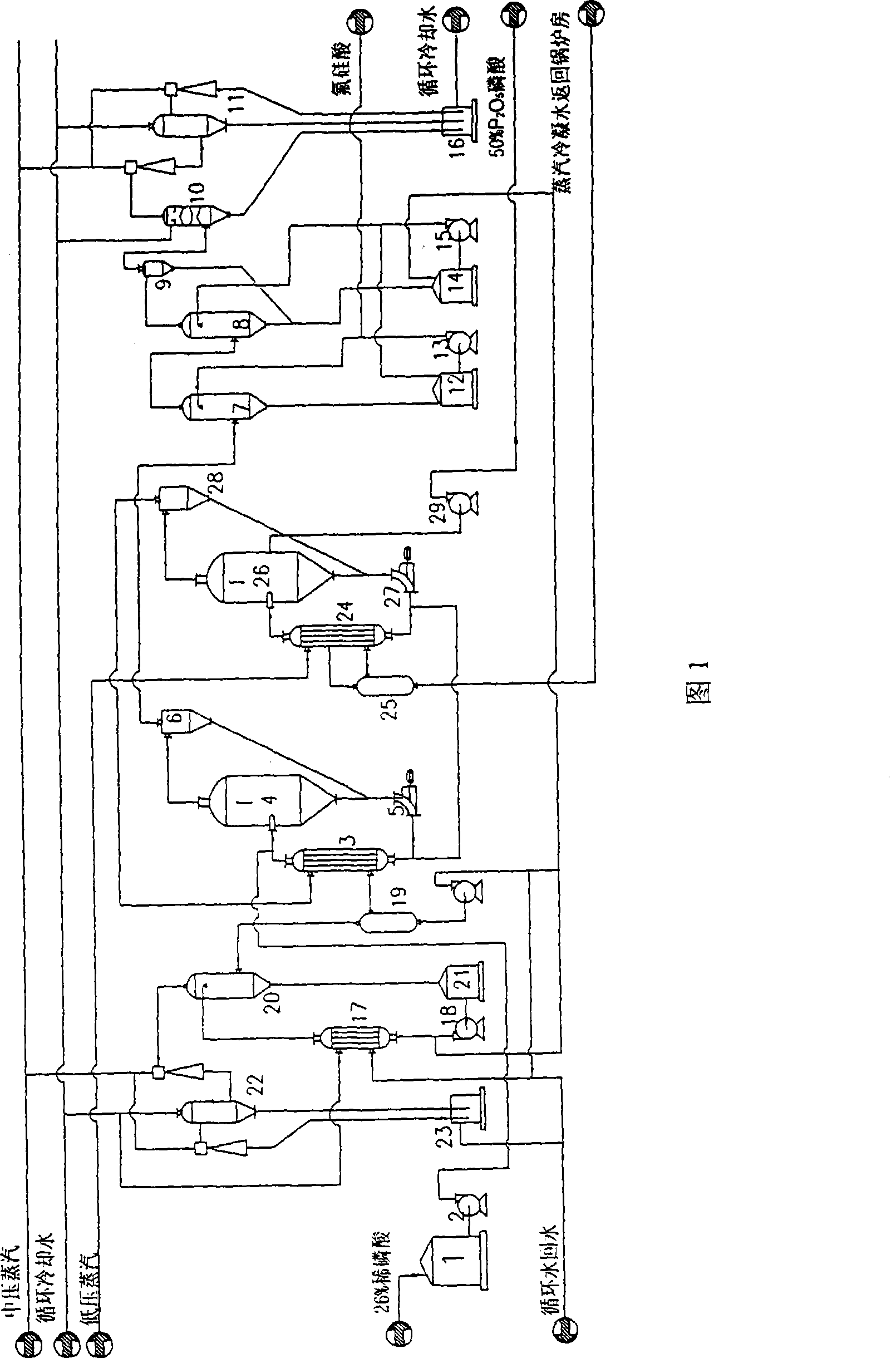

[0053] 1 block of 300,000 tons / year P 2 O 5 The phosphoric acid concentration unit consists of 3 production lines, each with a capacity of 100,000 tons / year. The process is shown in flow chart 1. Each line includes the following main equipment:

[0054] (1) I-effect heater shell and tube type F i =385m 2 Graphitized tube, carbon steel housing

[0055] (2) I-effect flash chamber D=1.8m carbon steel lined with butyl rubber or F4, bottom lined with carbon bricks

[0056] (3) I-effect circulating pump axial flow Q=5000m 3 / h H=4.6m pump casing impeller F33 or 2205

[0057] (4) II effect heater shell and tube type F i =200m 2 Graphitized tube, carbon steel lined with butyl rubber casing

[0058] (5) II-effect flash chamber D=3.8m carbon steel lined with butyl rubber, bottom lined with carbon bricks

[0059] (6) II-effect circulating pump axial flow Q=2580m 3 / h H=4.6m pump casing impeller F33 or CD4MCu

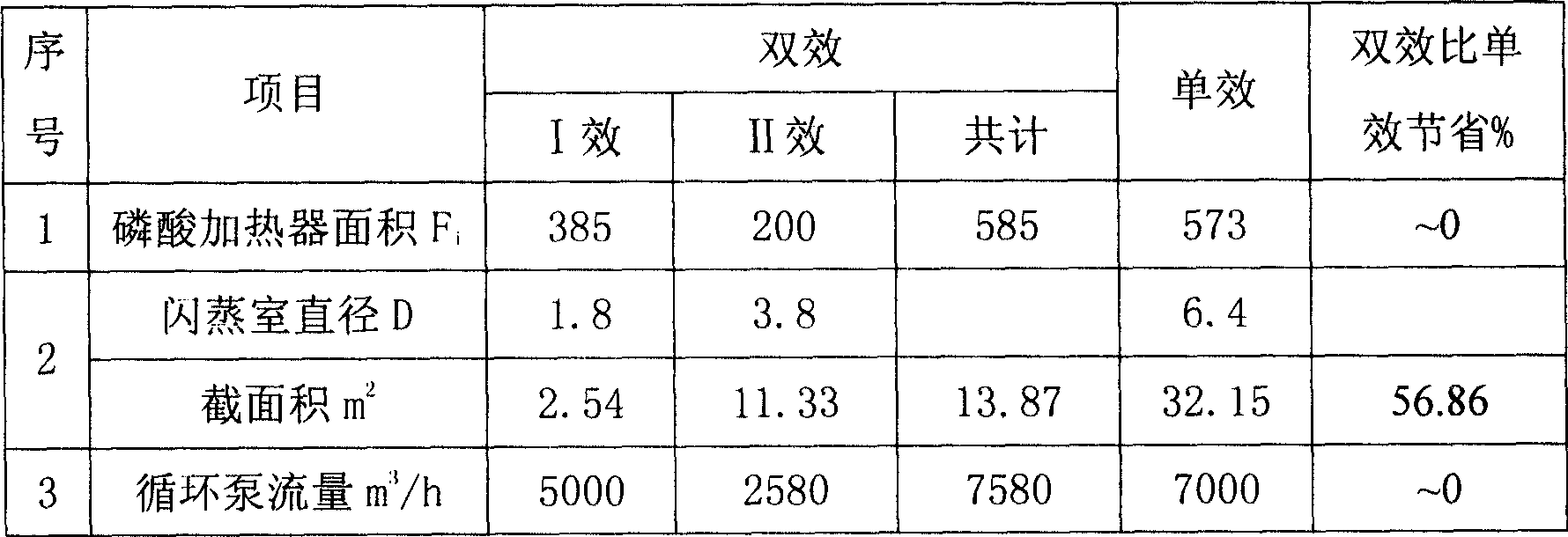

[0060] Comparison of main equipment between double-effect evaporati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com