Manufacturing method for fiber glass yarns and device therefor

A glass fiber and wool yarn technology, which is applied in the field of glass fiber wool yarn manufacturing, can solve problems such as difficult realization and shedding, and achieve the effects of convenient control, stable performance, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

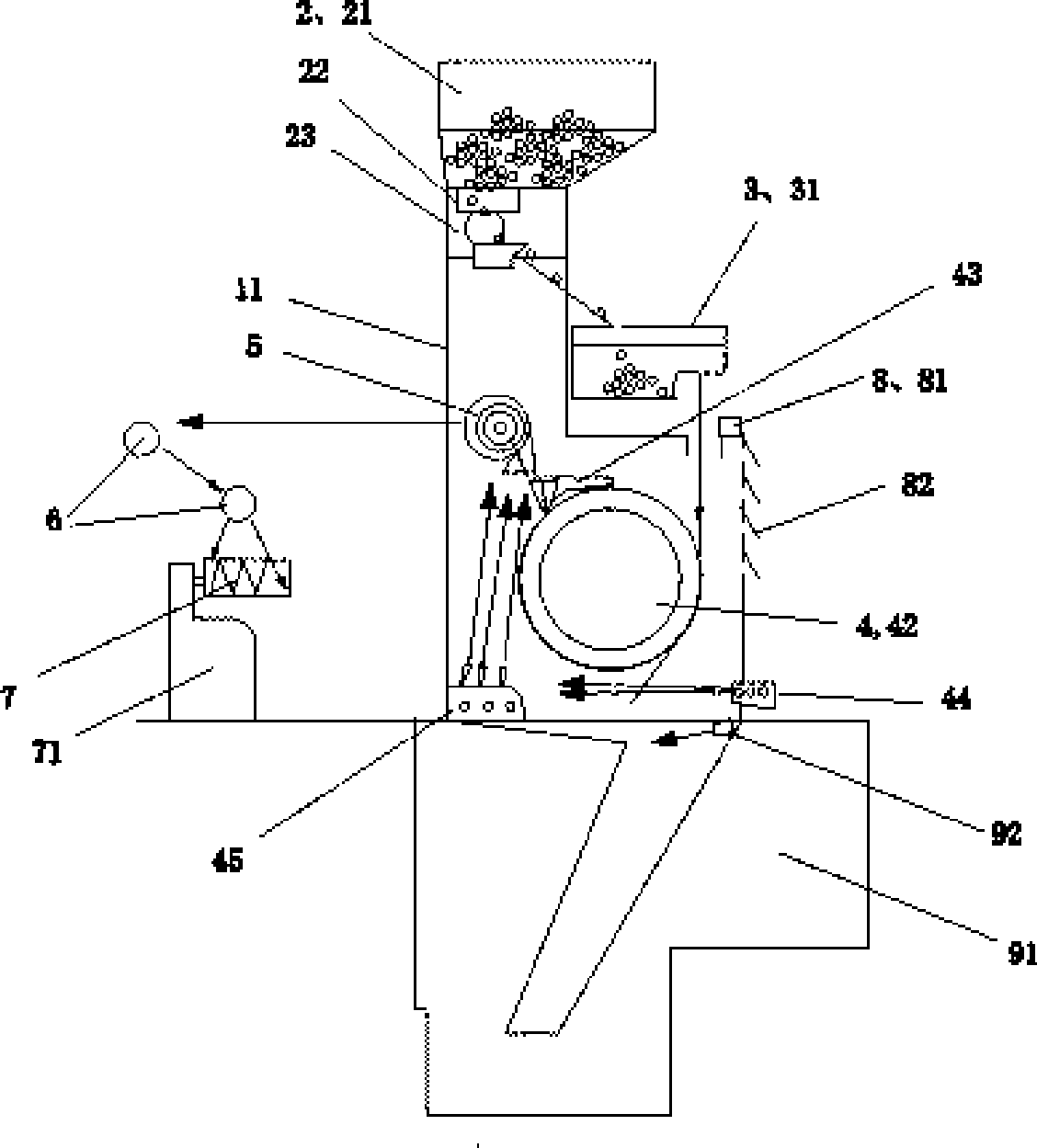

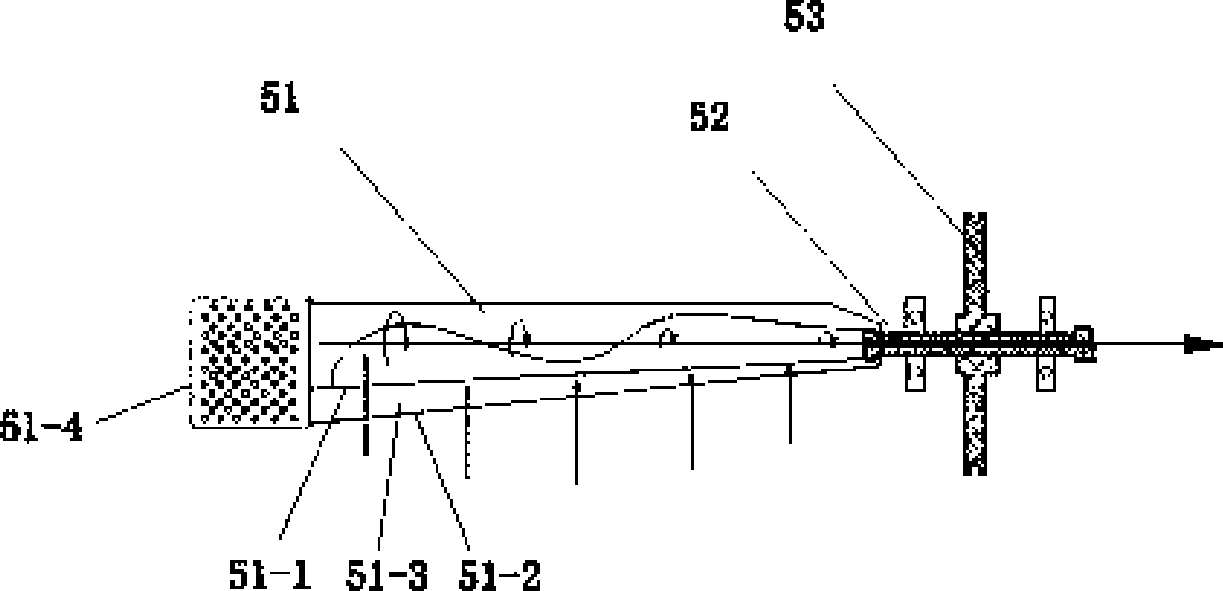

[0032] See figure 1 , the equipment of manufacturing glass fiber wool yarn of the present invention has frame, machine cover 11, feeding device 2, heating and melting device 3, cooling silk-forming device 4, puffing and twisting device 5, length measuring instrument 6, winder 7, Antistatic device 8 and control circuit.

[0033] The frame is fixed on the ground or the floor as the working surface, the machine cover 11 is fixed on the frame, and the control circuit is arranged in the control box fixed on the working surface.

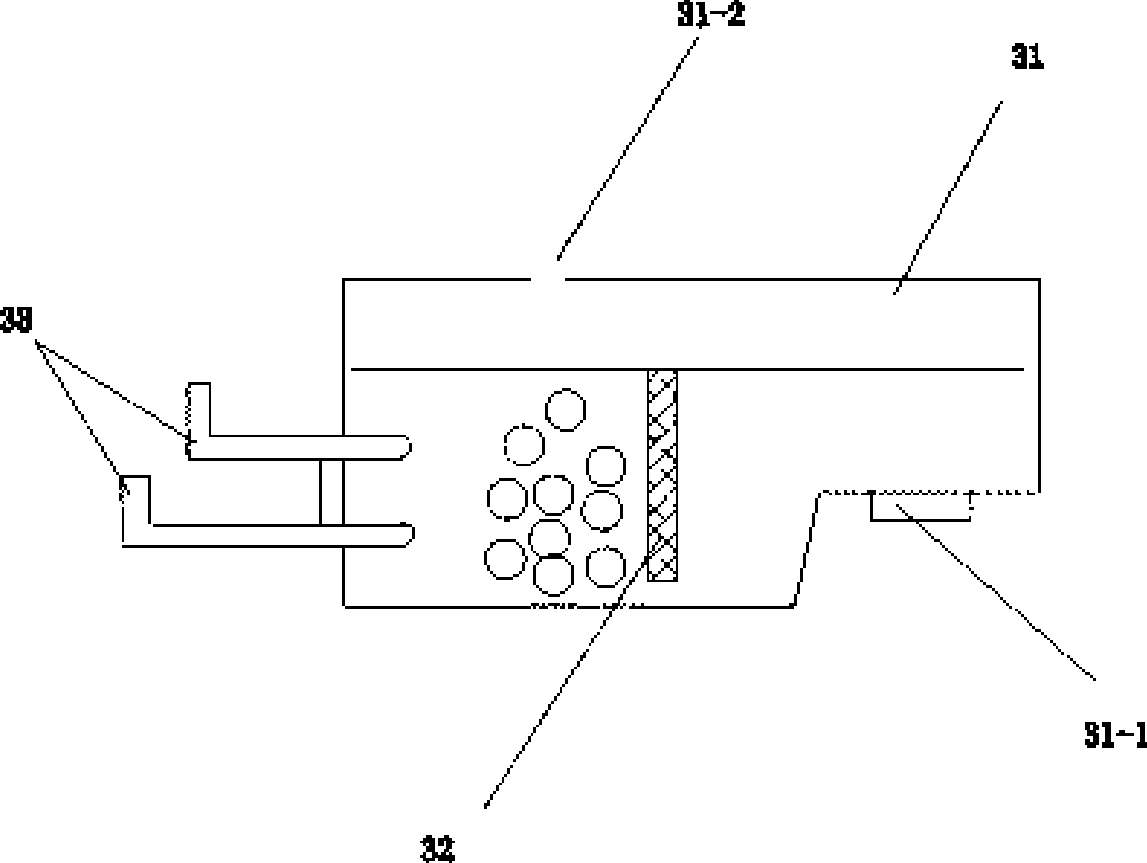

[0034]The feeding device 2 includes a feeding hopper 21 , an automatic metering feeder 22 and a feeding tank 23 . The feeding hopper 21 of the feeding device 2, the automatic metering feeder 22 and the feeding tank body 23 are all fixed on the frame, and the lower outlet of the feeder hopper 21 is connected with the feeding port of the automatic metering feeder 22, and the automatic metering The discharge port of the feeding machine 22 is located above t...

Embodiment 2

[0052] The equipment of this embodiment is the same as that of Example 1, and the manufacturing method is basically the same, except that the glass bulbs in step ① are high-alkali glass bulbs, the melting temperature is 960°C, and the liquefaction temperature is 1100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com