Process for preparing high-performance sensing film of fluorescent sensor by covalently immobilizing indicator dye

A fluorescence sensor, covalently immobilized technology, applied in the field of sensitive film, can solve the problems of slow reversibility of response, unsatisfactory reproducibility, unsuitable control of the thickness of sensor sensitive film, etc., to achieve good reversibility, avoid fluorescence extinction phenomenon, High sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

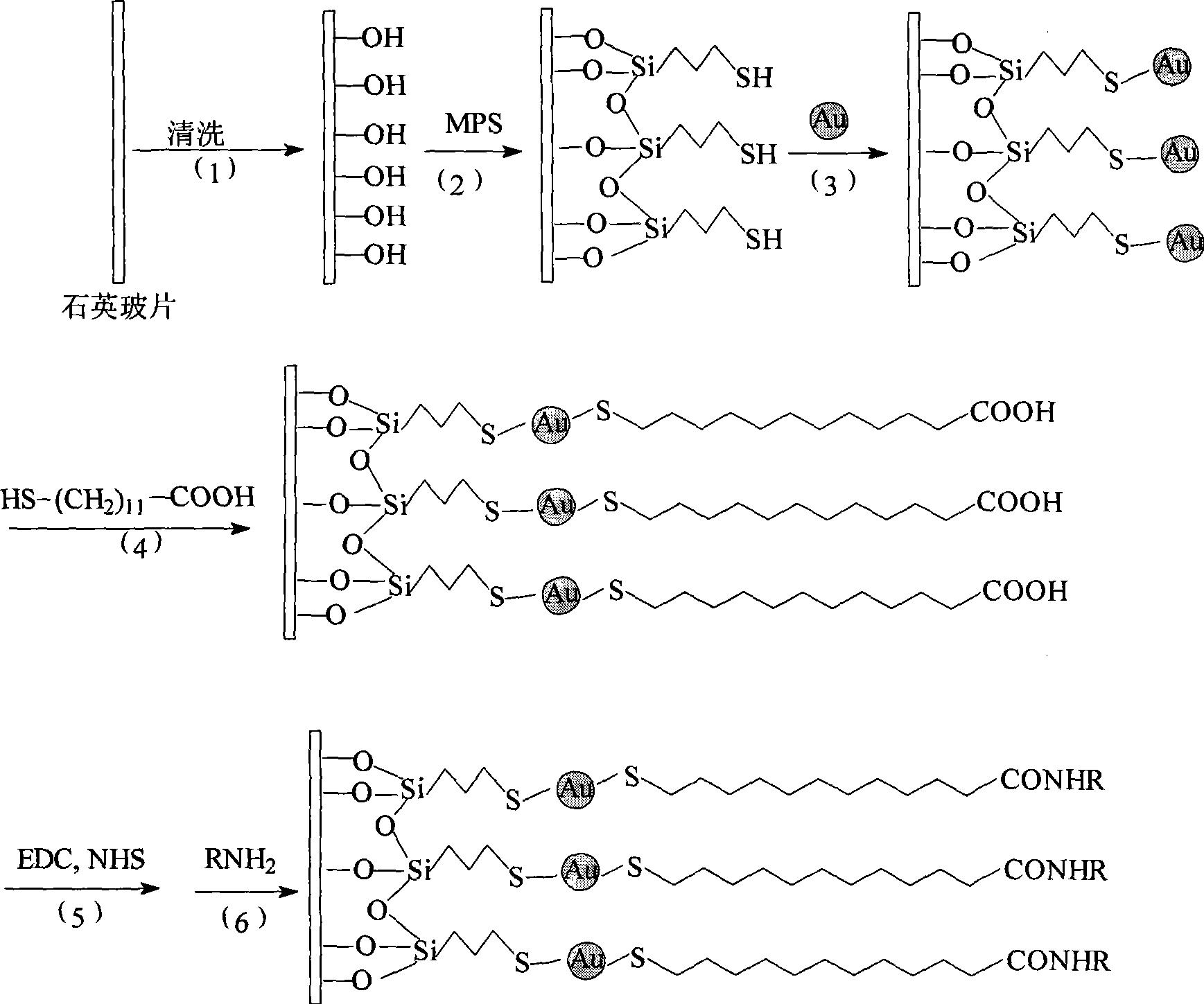

Embodiment 1

[0023] The preparation steps of the fluorescent sensor covalently immobilized 3-amino-9-ethylcarbazole: (1) cleaning of quartz glass slides: the slides were washed with 3% HF acid, 10% H 2 o 2 Clean, then rinse with distilled water, and dry at room temperature; (2) introduce mercapto groups on the quartz glass slide: mix 1mL of MPS, 4mL of water, 0.5mL of ethanol and 0.165mL of HCl (0.1mol L -1 ) mixing, followed by ultrasonication for 30 minutes to obtain a clear and uniform solution, and then placed at room temperature for 2-3 hours to obtain a silica sol. Place the cleaned glass slides in silica sol, take them out after 24 hours, wash them with water and ethanol in turn to remove the unbonded substances on the surface of the slides, a layer of MPS is bonded to the surface of the slides, and mercapto groups are introduced; (3) Fixation of gold nanoparticles: immerse the glass slide with mercapto groups introduced into the surface into the colloidal solution of gold nanopart...

Embodiment 2

[0026] The preparation steps of the fluorescent sensor of covalently immobilized 1-aminopyrene: the first (1)-(3) step is the same as in Example 1; (4) HS-(CH 2 ) 10 -Covalent immobilization of COOH: Immerse the slides immobilized with gold nanoparticles in a 2.0×10 -3 mol L -1 HS-(CH 2 ) 10 -COOH ethanol solution, take it out after 12h, and then rinse with ethanol to remove the mercaptocarboxylic acid that is not bonded on the surface of gold nanoparticles; -1 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) and 0.2mol L -1 N-hydroxysuccinimide (NHS) was mixed in equal volumes, and then the glass slides obtained in (4) were immersed in the mixed solution for 2 hours, washed with ethanol and distilled water successively after taking out, and then dried at room temperature; (6) Covalent immobilization of 1-aminopyrene: immerse the glass slide obtained in (5) in an acetone solution of 1-aminopyrene (1.0×10 -3 mol L -1 ), take it out after 6h, wash with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com