Method for preparing solar battery photo-anode substrate

A solar cell and photoanode technology, applied in capacitor electrodes, circuits, photovoltaic power generation, etc., can solve the problem of low photoelectric conversion efficiency of solar cells DSC cells, and achieve the goal of improving photoelectric conversion efficiency, increasing effective use area, and avoiding direct contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Take ordinary glass as the substrate, soak it with distilled water, analytically pure acetone and aqueous solution respectively, clean it in an ultrasonic cleaner for 15 minutes, and dry it for later use;

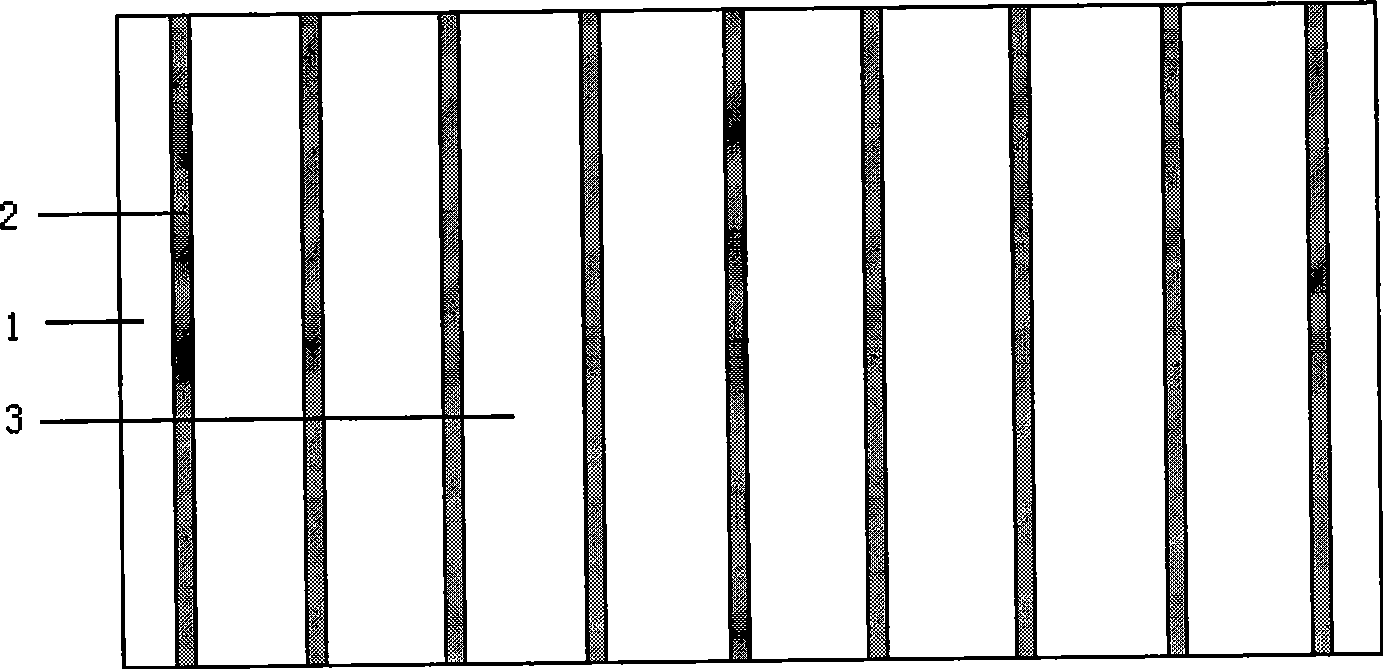

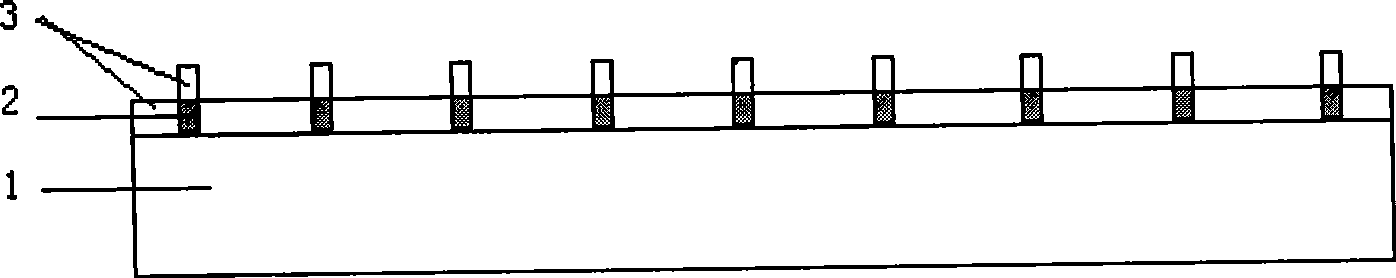

[0025] 2) On the cleaned glass substrate, print the required metal grid pattern with metal paste, and the parameters used for printing are as follows:

[0026] ①Screen printing machine inlet pressure: 0.4Mpa; scraper pressure: 0.2Mpa; scraper pressure: 0.25Mpa; scraper angle: 70°; scraper downward pressure: 0.5mm; scraper travel speed setting: 50mm / s;

[0027] ②The material used for printing is metal electronic paste, and silver with good conductivity is used as the metal electronic paste for printing;

[0028] ③The size of the screen printing screen is 250 mesh;

[0029] ④The degassing temperature is 370°C; the degassing holding time: 10min; the sintering temperature: 450°C; the sintering holding time is 30min, and the resistance value of the grid line is 0.05mΩ...

Embodiment 2

[0035] 1) Take ordinary glass as the substrate, soak it with distilled water, analytically pure acetone and aqueous solution respectively, clean it in an ultrasonic cleaner for 15 minutes, and dry it for later use;

[0036] 2) On the cleaned glass substrate, print the required metal grid pattern with metal paste, and the parameters used for printing are as follows:

[0037] ①Screen printing machine inlet pressure: 0.5Mpa; scraper pressure: 0.25Mpa; scraper pressure: 0.2Mpa; scraper angle: 70°; scraper downward pressure: 0.5mm; scraper travel speed setting: 10mm / s;

[0038] ②The material used for printing is metal electronic paste, and platinum with good conductivity is used as the metal electronic paste for printing;

[0039] ③The size of the screen printing screen is 400 mesh;

[0040] ④The degassing temperature is 250°C; the degassing holding time: 30min; the sintering temperature: 580°C; the sintering holding time is 10min, and the resistance value of the grid line is 1Ω; ...

Embodiment 3

[0046] 1) Take ordinary glass as the substrate, soak it with distilled water, analytically pure acetone and aqueous solution respectively, clean it in an ultrasonic cleaner for 15 minutes, and dry it for later use;

[0047] 2) On the cleaned glass substrate, print the required metal grid pattern with metal paste, and the parameters used for printing are as follows:

[0048] ①Screen printing machine inlet pressure: 0.45Mpa; scraper pressure: 0.23Mpa; scraper pressure: 0.23Mpa; scraper angle: 70°; scraper downward pressure: 0.5mm; scraper travel speed setting: 30mm / s;

[0049] ② The material for printing is metal electronic paste, and gold with good conductivity is used as the metal electronic paste for printing;

[0050] ③The size of the screen printing screen is 320 mesh;

[0051] ④The degassing temperature is 310°C; the degassing holding time: 20min; the sintering temperature: 500°C; the sintering holding time is 20min, and the resistance value of the grid wire is 0.1Ω;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com