High-grade porket granule feedstuff

A technology for pellets and suckling pigs, applied in the field of suckling pig feed, can solve the problems of low digestion and absorption rate, single composition, poor palatability, etc., and achieve the effects of improving economic benefits, reducing formula costs, and improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

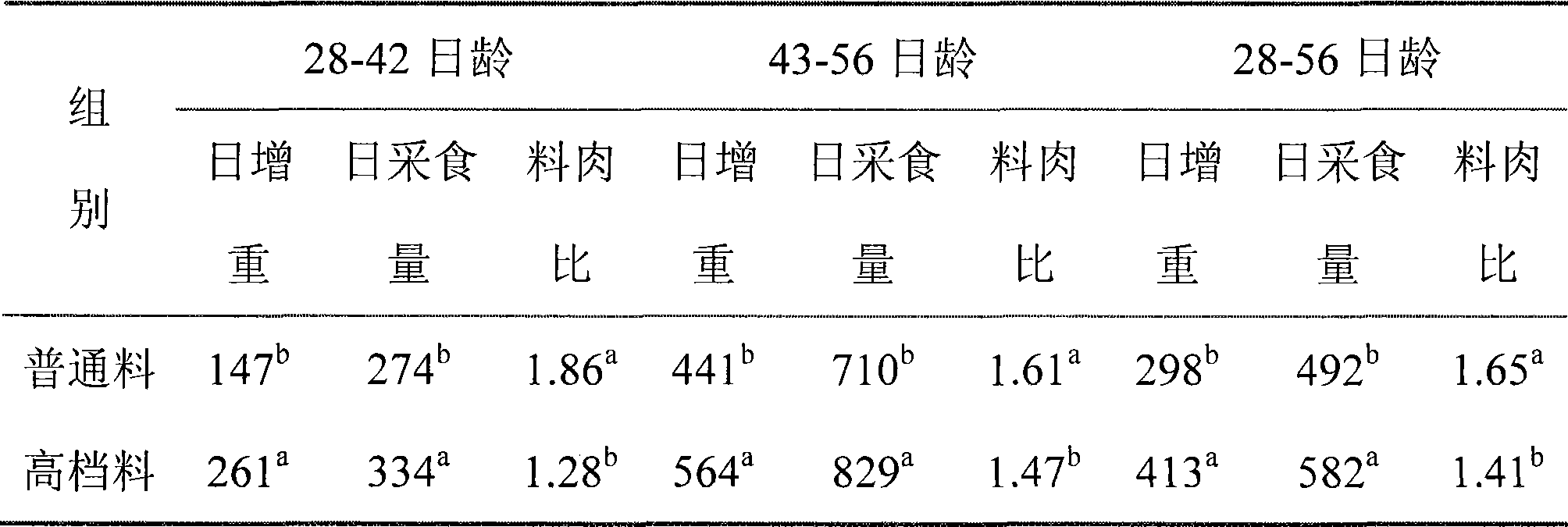

Embodiment 1

[0033] The high-grade suckling pig pellets in this embodiment are divided into two stages, the first stage is the trough-42 days old pellets, and the second stage is from 43-56 days old pellets, wherein the weight of each component in the first stage The content is: 245 parts of first-grade corn, 265 parts of puffed corn, 8 parts of second-grade soybean oil, 120 parts of puffed soybean, 30 parts of medium-protein soybean meal, 40 parts of imported fish meal, 40 parts of plasma protein powder, 41 parts of intestinal Taikang, 40 parts of nutritional pie 3 parts of fine stone powder, 15 parts of calcium hydrogen phosphate, 82 parts of high protein whey powder, 45 parts of fine white sugar, 5 parts of lysine, 1.2 parts of methionine, 1.8 parts of threonine, 2 parts of zinc oxide, 2 15 parts of high-grade suckling pig premix; the weight content of each component in the second stage is: 568.4 parts of first-grade corn, 10 parts of second-grade soybean oil, 145 parts of puffed soybea...

Embodiment 2

[0036] The high-grade suckling pig pellets in this embodiment are divided into two stages, the first stage is the trough-42 days old pellets, and the second stage is from 43-56 days old pellets, wherein the weight of each component in the first stage The content is: 244.4 parts of first-grade corn, 270 parts of puffed corn, 10 parts of second-grade soybean oil, 120 parts of puffed soybean, 35 parts of medium-protein soybean meal, 30 parts of imported fish meal, 40 parts of plasma protein powder, 45 parts of intestinal Taikang, 35 parts of nutritional pie 4 parts of fine stone powder, 12 parts of calcium hydrogen phosphate, 85 parts of high protein whey powder, 45 parts of fine white sugar, 4 parts of lysine, 1.2 parts of methionine, 1.9 parts of threonine, 2.5 parts of zinc oxide, 2% milk 15 parts of high-grade pig premix; the weight content of each component in the second stage is: 569.1 parts of first-grade corn, 20 parts of second-grade soybean oil, 145 parts of puffed soybe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com