Method for preparing nano pseudo boehmite and microchannel reactor

A technology of microchannel reactor and pseudo-boehmite, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., to achieve the effects of controllable particle size, large operating flexibility, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Dissolve 9.84 grams of sodium aluminate in 200 ml of tap water to prepare a 0.6 mol / l solution, and dissolve 6.84 g of aluminum sulfate in 200 ml of tap water to prepare a 0.1 mol / l solution.

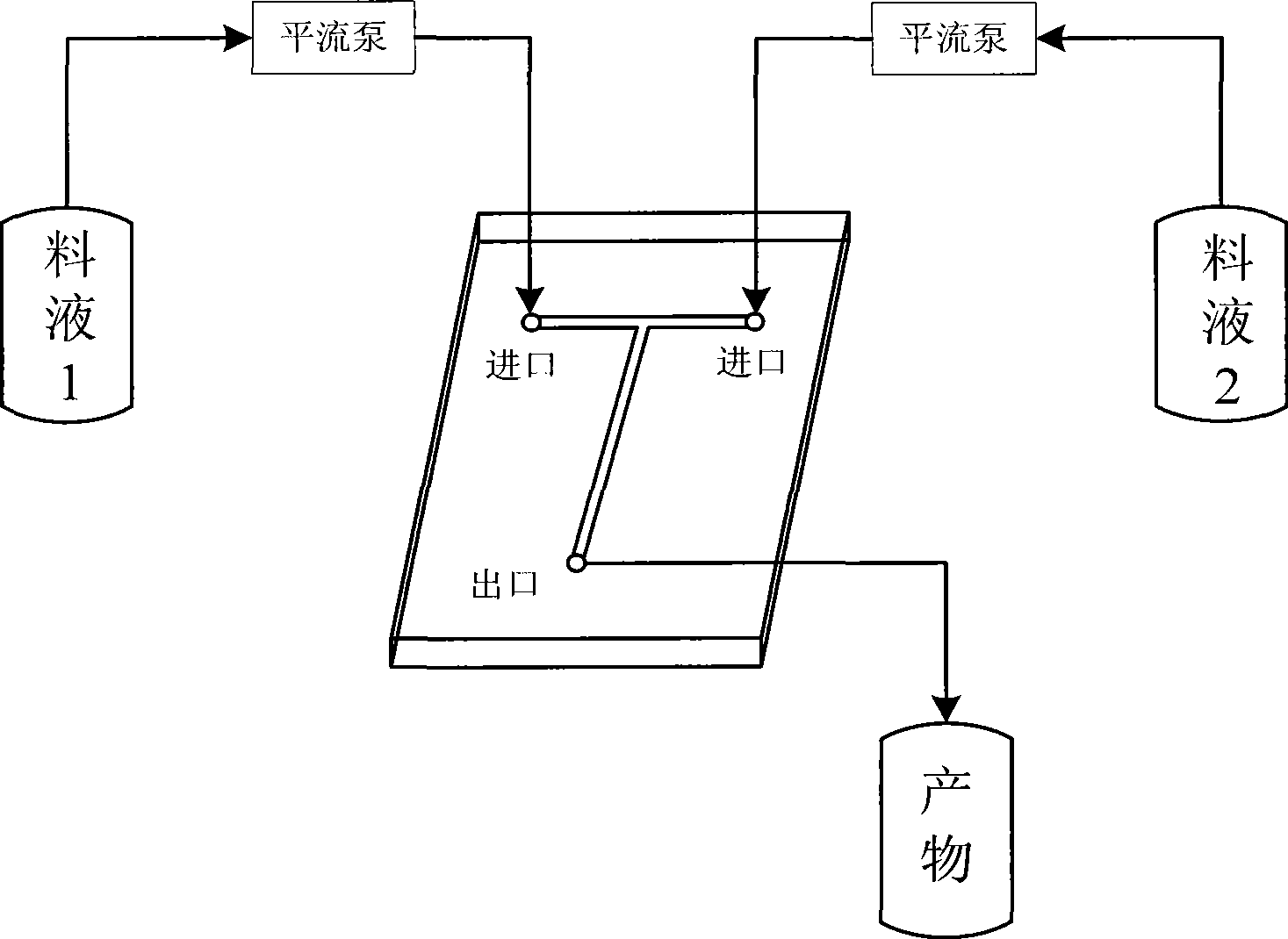

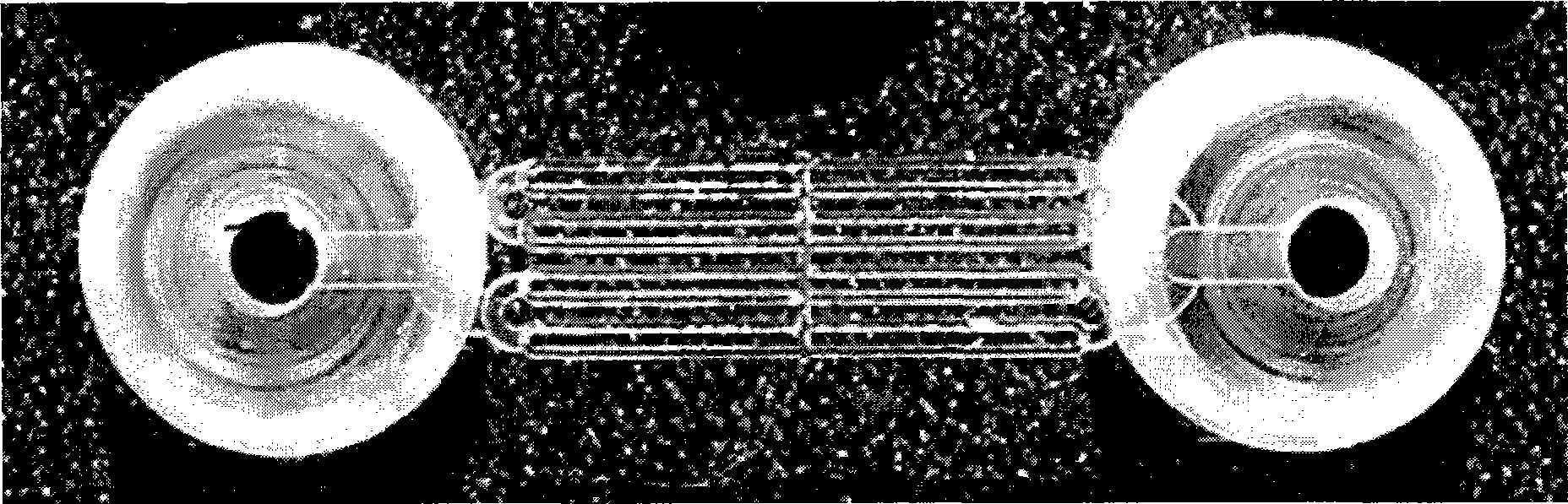

[0041] 2) Use two advection pumps to input sodium aluminate and aluminum sulfate solutions into the two inlets of the single-channel reactor respectively, and the two solutions collide and mix at the interface, and continue to react along the reaction channel. Maintain the flow rate of aluminum sulfate at 9ml / min, adjust the flow rate of sodium aluminate solution, and measure the pH value of the product at the outlet to be 7.5.

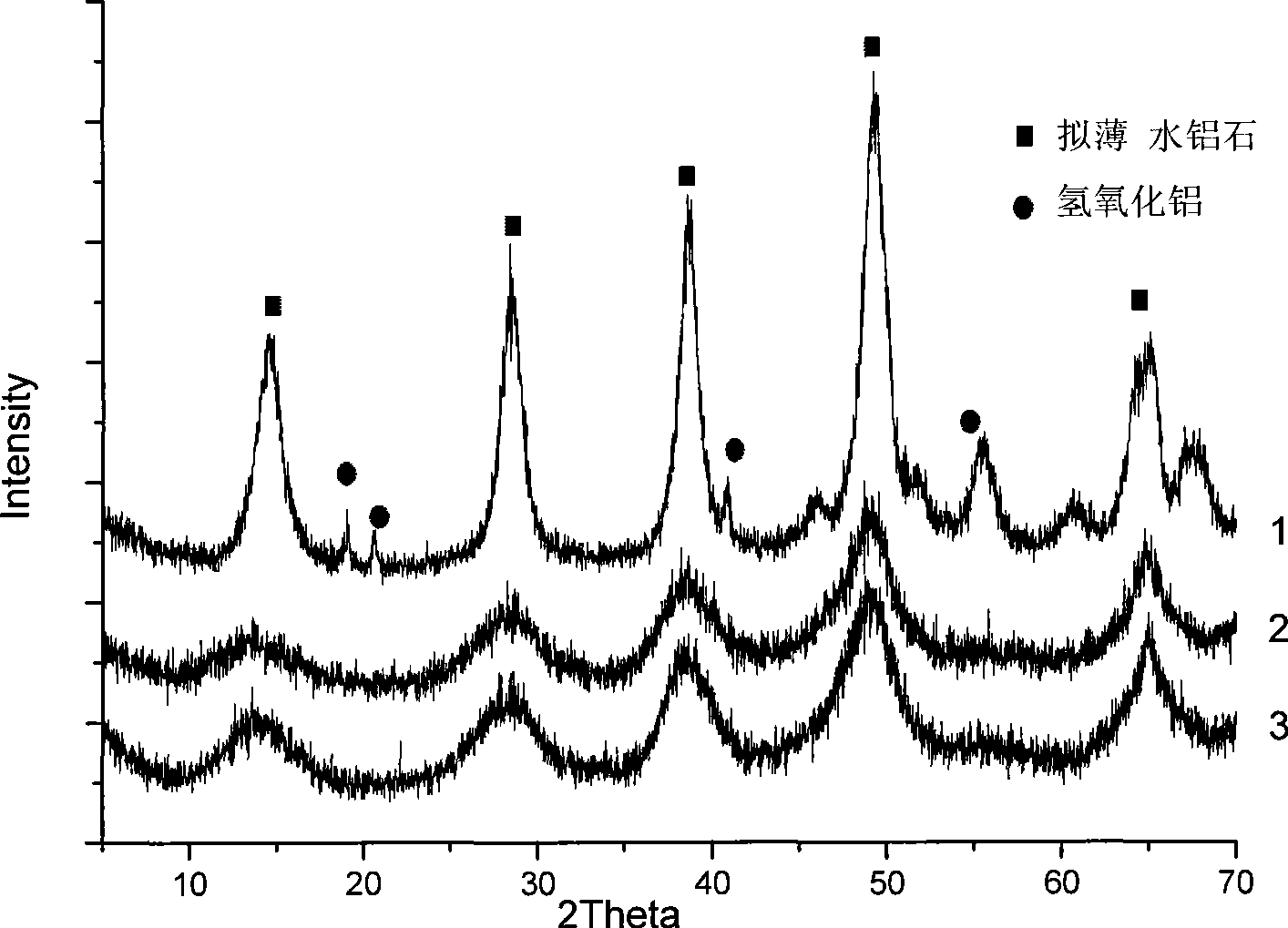

[0042] 3) Collect the aluminum salt solution at the outlet, add a small amount of Na 2 CO 3 solution, adjust the pH to 9. Put into 45 ℃ water bath and age for 24h. Then wash 3 times with centrifuge. Put it in an oven and heat it at 110°C for 10 hours, then dry it, and the conversion rate of the raw material is 100%. The dried product is ground int...

Embodiment 2

[0044] 1) Dissolve 4.92g of sodium aluminate in 200ml of tap water to prepare a 0.3mol / l solution, and dissolve 3.42g of aluminum sulfate in 200ml of tap water to prepare a 0.05mol / l solution.

[0045] 2) Use two advection pumps to input sodium aluminate and aluminum sulfate solutions to the two inlets of the single-channel reactor respectively, and the two solutions collide and mix at the interface and react along the reaction channel. The constant aluminum sulfate flow rate is 8ml / min, regulates the flow rate of sodium aluminate solution, and the pH value of the product measured at the outlet is 8.

[0046] 3) Collect the aluminum salt solution at the outlet, add a small amount of Na 2 CO 3solution to bring the pH to 9.5. Put it into a 60°C water bath for aging for 4 hours. Then wash 3 times with centrifuge. Put it in an oven and heat it at 110°C for 10 hours, then dry it, and the conversion rate of the raw material is 100%; grind the dried product into powder to obtain ...

Embodiment 3

[0048] The constant aluminum sulfate flow rate is 9ml / min, the flow rate of sodium aluminate solution is adjusted, and the pH value of the product measured at the outlet is 6. Collect the aluminum salt solution at the outlet, add a small amount of Na 2 CO 3 solution to bring the pH to 8.5. Aging at room temperature of 25°C for 48h. All the other conditions are with embodiment 1. Finally, the nano-scale target product—pure pseudo-boehmite is obtained, and the conversion rate of raw materials is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com