Liquid crystal photo-alignment agent and liquid crystal photo-alignment film and liquid crystal display

一种光取向、液晶的技术,应用在LCD。领域,能够解决集聚、不能形成均匀膜等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

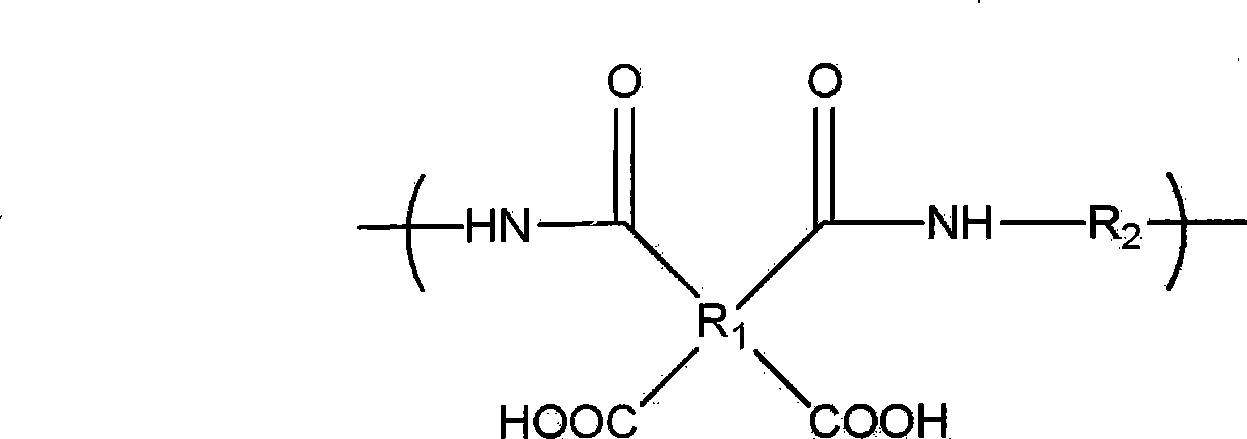

[0211] Preparation Example 1: Preparation of Polyamic Acid Copolymer (PAA-1)

[0212] 0.7 mol of phenylenediamine, 0.15 mol of functional diamine 3,5-diaminophenyldecylsuccinimide of following chemical formula 24 and 0.15 mol of the following chemical formula 25 of diaminobenzoic acid 4-(2-ethoxycarbonyl-vinyl)-phenyl ester was added to a four-necked flask equipped with a stirrer, a temperature controller, a nitrogen injector and a cooler, and nitrogen was fed from beginning to end, and N-methyl -2-pyrrolidone (NMP) was added thereto to obtain a mixed solution.

[0213] [Chemical formula 24]

[0214]

[0215] [Chemical formula 25]

[0216]

[0217] In the above general formula 25, n=2.

[0218] 1.0 mol of solid 1,2,3,4-cyclobutyltetracarboxylic dianhydride was added to the above mixed solution and vigorously stirred. The amount of solids is 20% by weight. The reaction was carried out for 10 hours while the temperature was kept at 30° C. to 50° C. to obtain a polyami...

preparation example 2

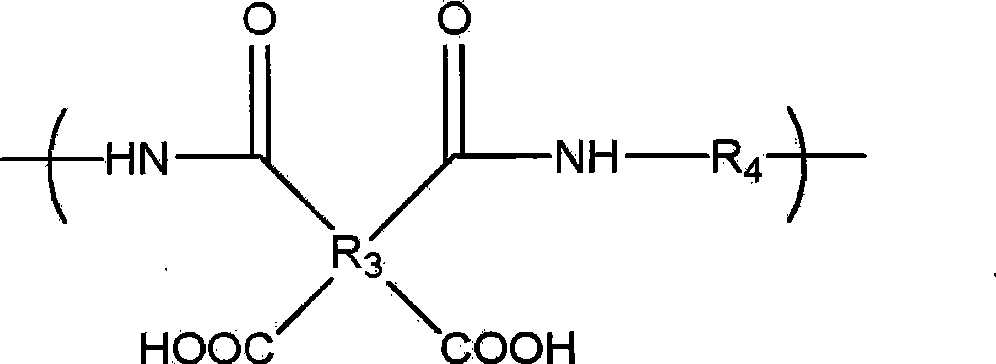

[0219] Preparation Example 2: Preparation of Polyamic Acid Copolymer (PAA-2)

[0220] The polyamic acid solution (PAA-2) was prepared according to the same process as Preparation Example 1, except that the functional diamine shown in the following chemical formula 26 was used instead of the functional diamine shown in chemical formula 24.

[0221] [Chemical formula 26]

[0222]

preparation example 3

[0223] Preparation Example 3: Preparation of Polyamic Acid Copolymer (PAA-3)

[0224] The polyamic acid solution (PAA-3) was prepared according to the same process as Preparation Example 1, except that the functional diamine shown in the following chemical formula 27 was used instead of the functional diamine shown in chemical formula 24.

[0225] [Chemical formula 27]

[0226]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com