Method for preparing semi-conducting material nano structure aluminum nitride

A technology of aluminum nitride and semiconductors, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of inability to form in large quantities, high production costs, environmental pollution, etc., achieve low temperature, low cost, and simple methods fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

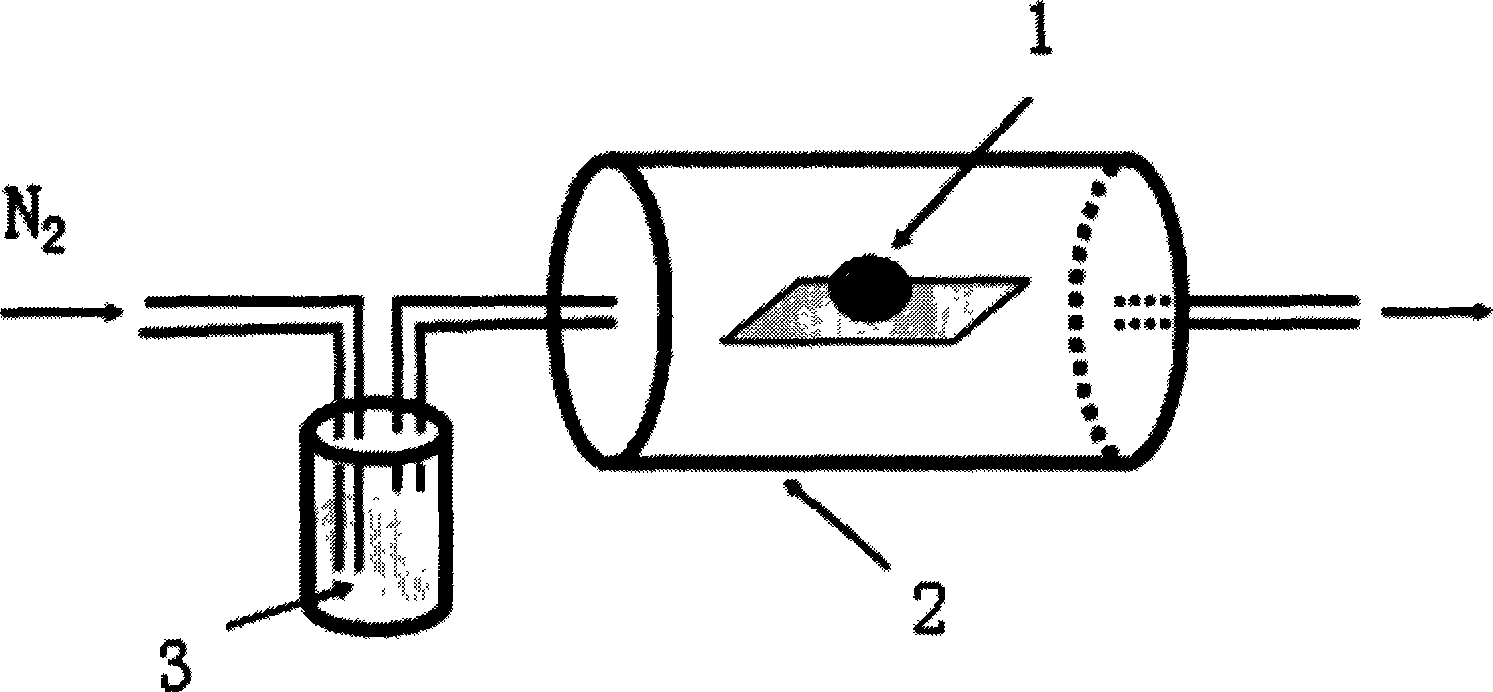

[0018] A method for preparing semiconductor material nanostructure aluminum nitride according to the present invention, the preparation process is completed in a reaction tube, the reaction tube is a quartz tube, or a corundum tube or other high temperature resistant tubes, specifically comprising the following steps:

[0019] The aluminum powder is first ground to a particle diameter between 1 micron and 50 nanometers.

[0020] The ground powder is placed in the reaction tube, nitrogen gas is passed through, the nitrogen gas is dried, and the nitrogen flow is between 20 sccm and 300 sccm; the gas desiccant used for drying the nitrogen gas can be concentrated sulfuric acid or calcium oxide or calcium sulfate.

[0021] Heat the reaction tube with a heating device to make the nitrogen and the steam generated by the aluminum powder react; the heating temperature is 700-1200°C, and the heating time is 30 minutes to 5 hours.

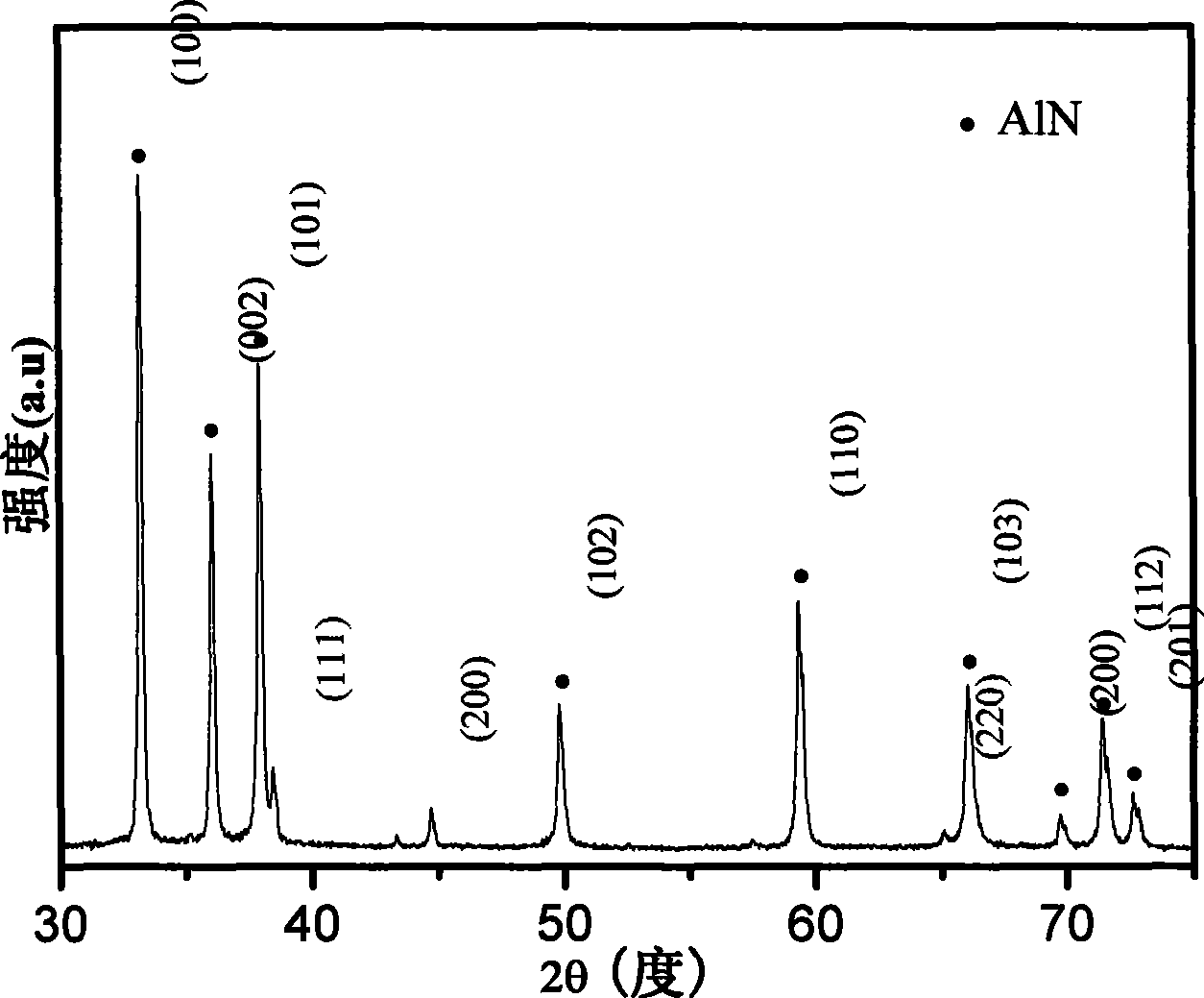

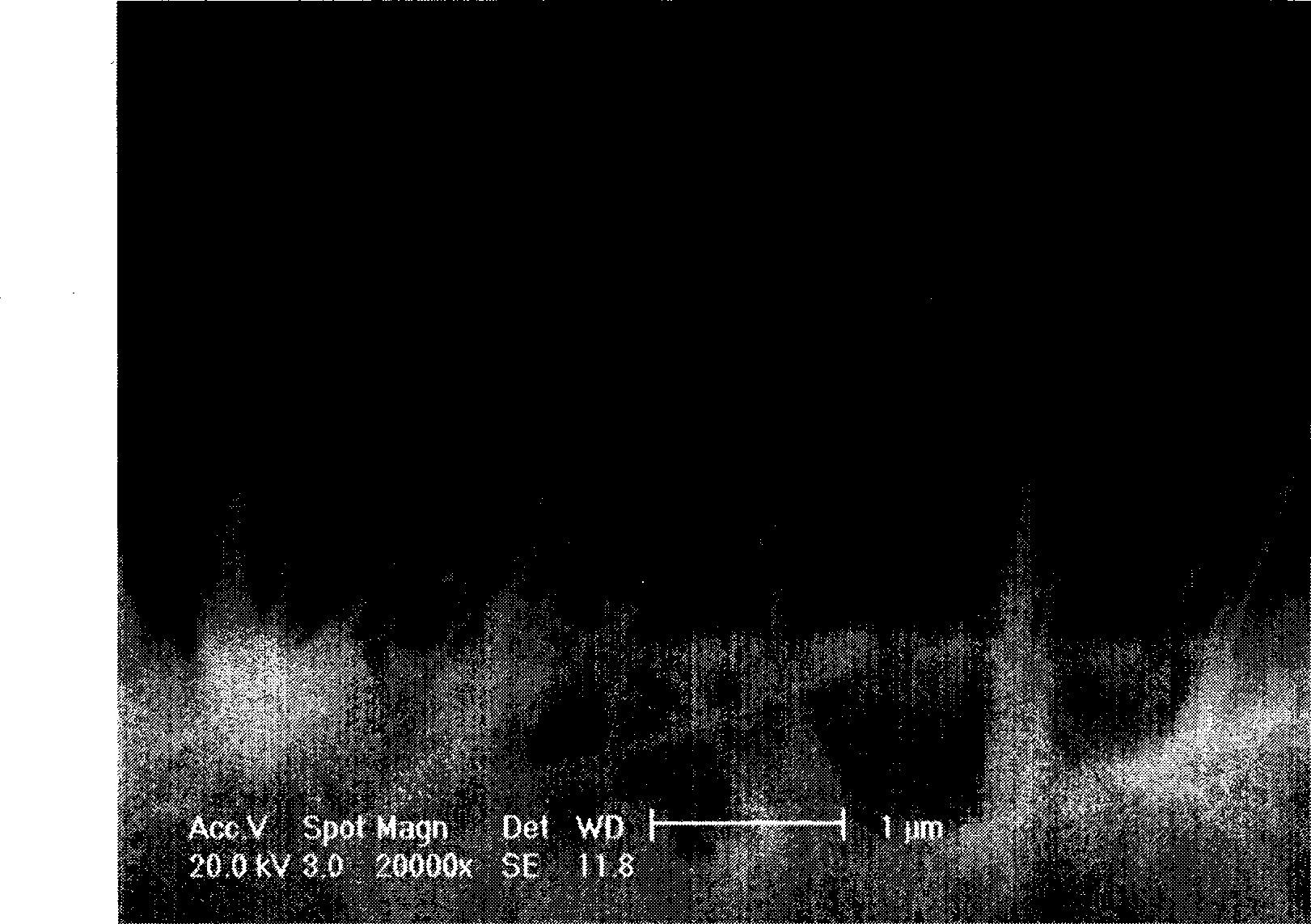

[0022] After the reaction, a large number of aluminum n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com