Boron carbide base composite ceramic and preparation method thereof

A technology of composite ceramics and boron carbide, which is applied in the field of boron carbide-based composite ceramics and its preparation, can solve the problems of large line shrinkage before and after sintering of products, difficulty in preparing products with shape changes, high inability to scale production, etc., to improve oxidation resistance , high elastic modulus, high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

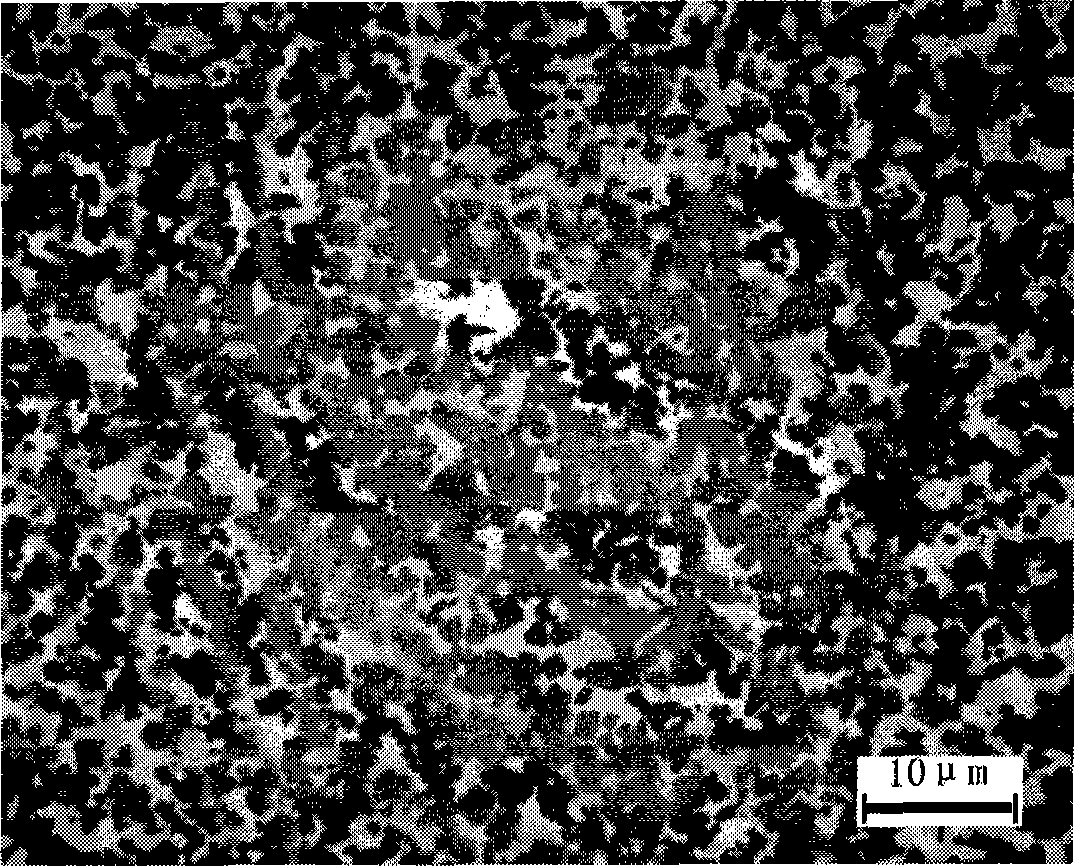

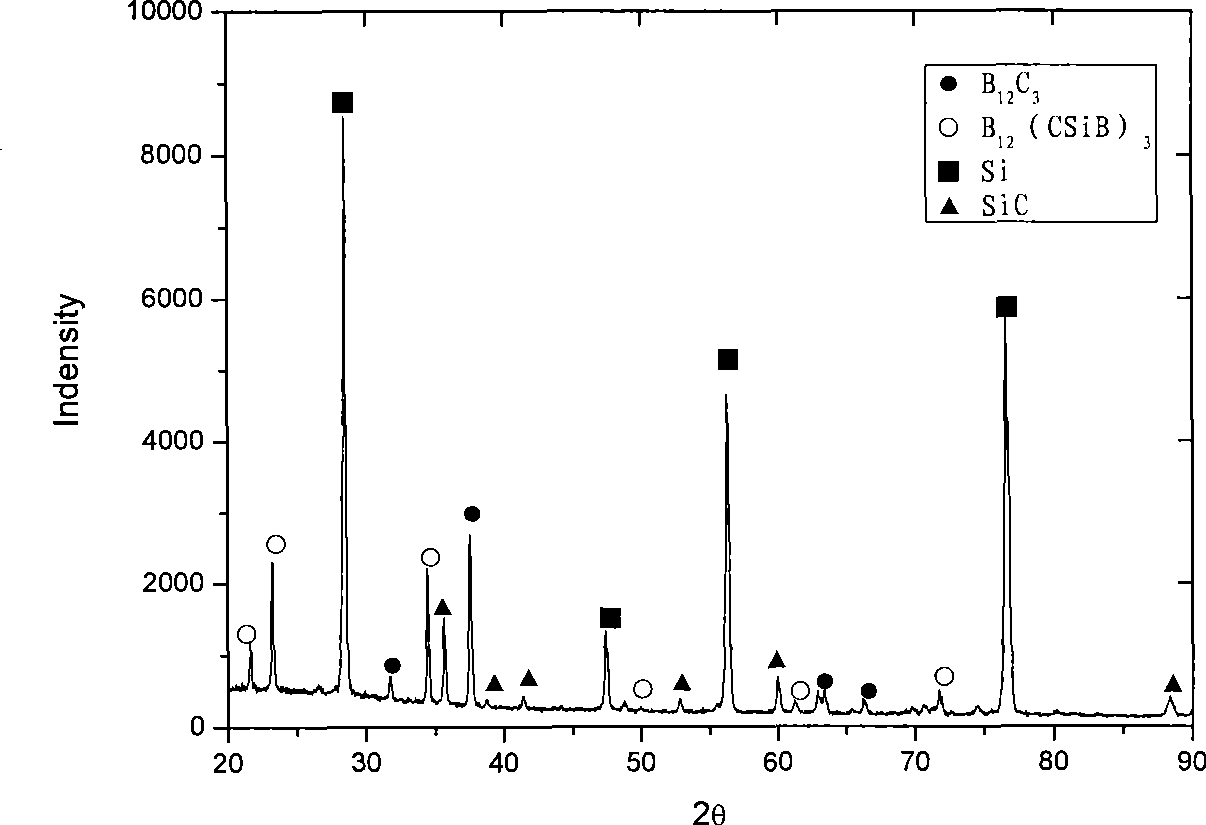

Image

Examples

Embodiment Construction

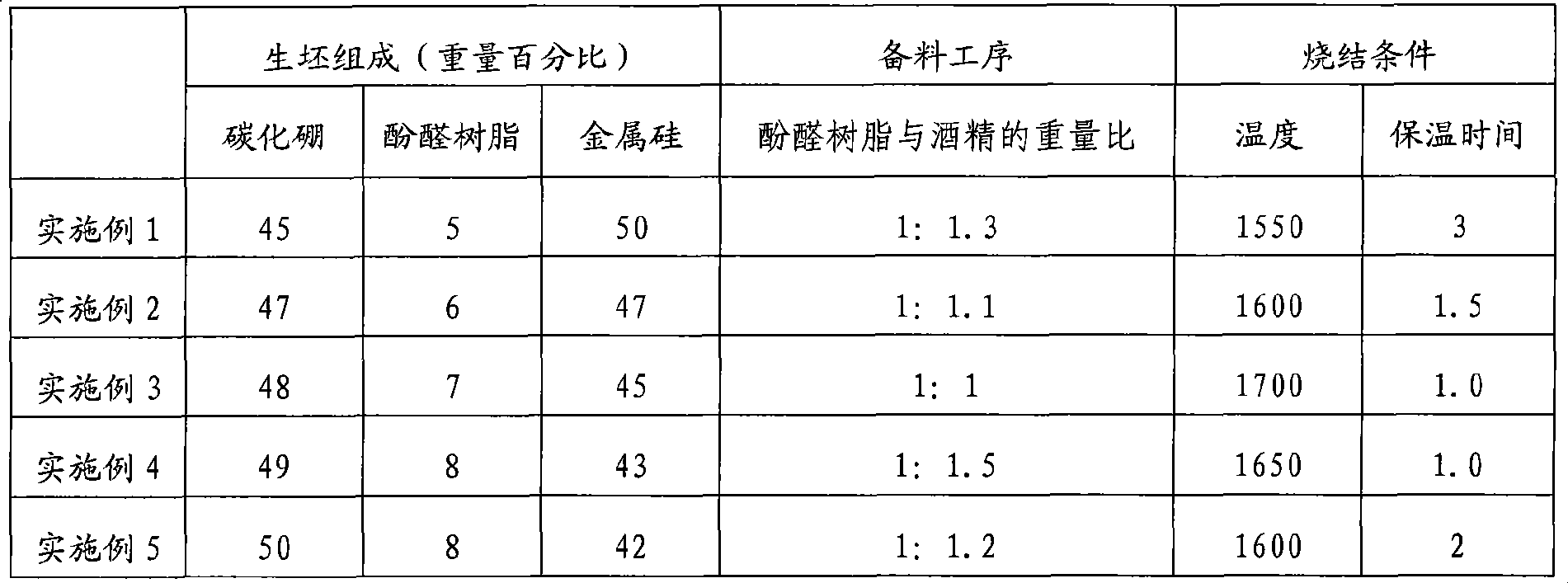

[0025] The present invention will be further described in detail below in conjunction with specific examples.

[0026] A boron carbide-based composite ceramic, the composition of which is shown in Table 1, in Examples 1-5 shown in Table 1. The percentage content of the boron carbide phase in the obtained product is generally 70-85%. If it is less than 70%, the boron carbide content in the sintered body is too small, the hardness of the sintered material is low, and the mechanical properties of the sintered body are reduced. If it is greater than 85%, the sintered body is prone to impermeability.

[0027] The percentage of phenolic resin in the green body is preferably 5-10%. If it is less than 5%, the strength of the green body is too low, the bonding performance of the powder is poor, and the forming performance is poor. If it exceeds 10%, more pores will be formed after the cracking of the phenolic resin, the amount of residual silicon will increase, and the mechanical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com