Nanogold Colloid for responding heavy metal ion and method for making same

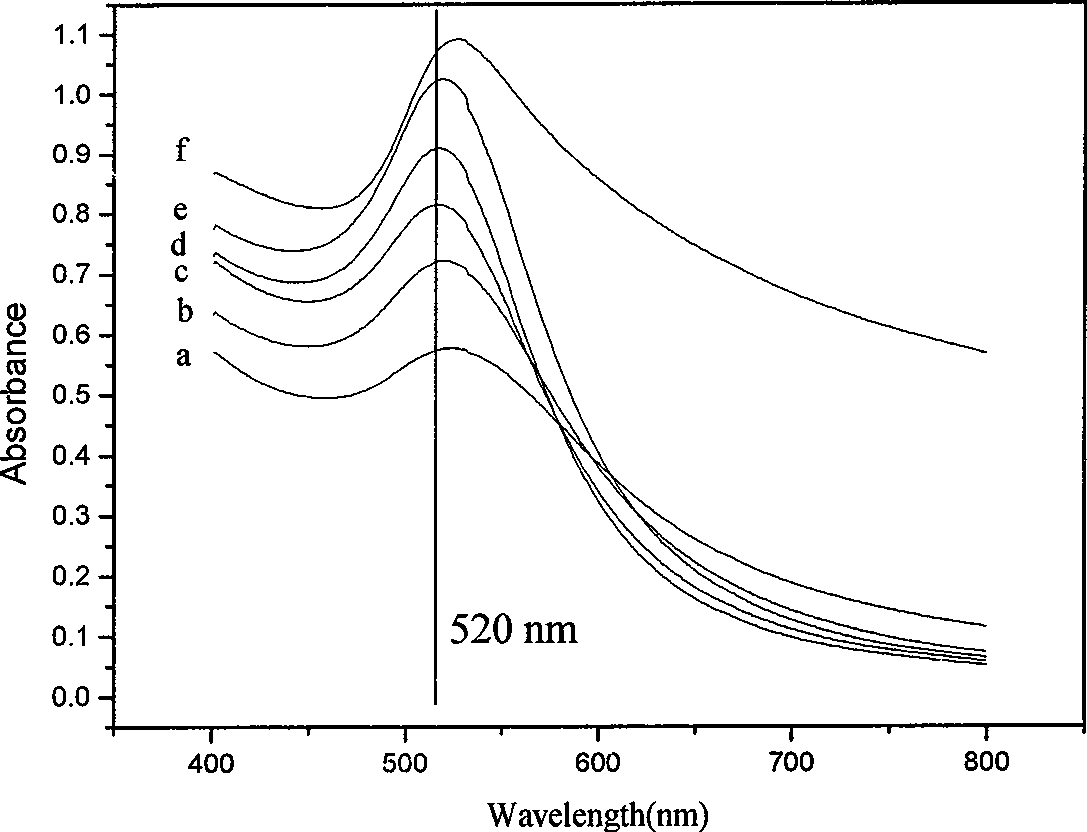

A technology of gold nano sol and heavy metal ions, which is applied in the field of gold nano materials, can solve the problems of insufficient stability of gold nanoparticles and insufficient sensitivity of heavy metal response, and achieve the effects of low manufacturing cost, long shelf life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

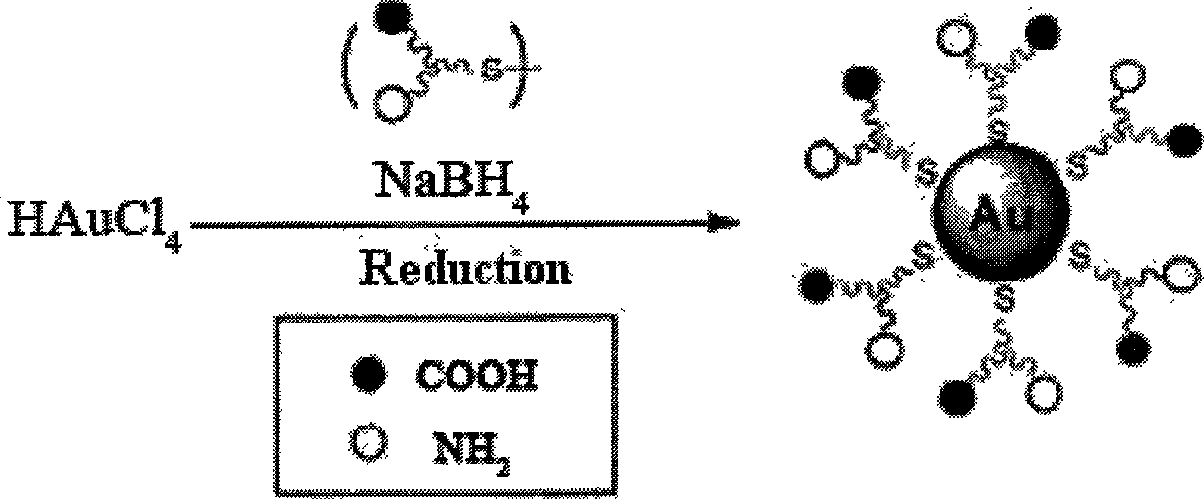

[0053] (1) Use ultrapure water to make chloroauric acid into an aqueous solution with a concentration of 0.53mmol / L, then add 0°C methanol to the chloroauric acid aqueous solution, the volume ratio of chloroauric acid aqueous solution to methanol is 1:1, and ultrasonically Shock.

[0054] (2) Add a concentration of 0.002g / ml L-cysteine aqueous solution to the chloroauric acid solution obtained in step 1, so that the molar ratio of L-cysteine to chloroauric acid is 1:3, and ultrasonically vibrate well mixed.

[0055] (3) Add dropwise a methanol solution of sodium borohydride with a concentration of 0.002g / ml to the mixed solution obtained in step 2, the molar ratio of sodium borohydride to chloroauric acid is 8:1, and the S / Au obtained by ultrasonic vibration is 1 :3 gold nano-sol.

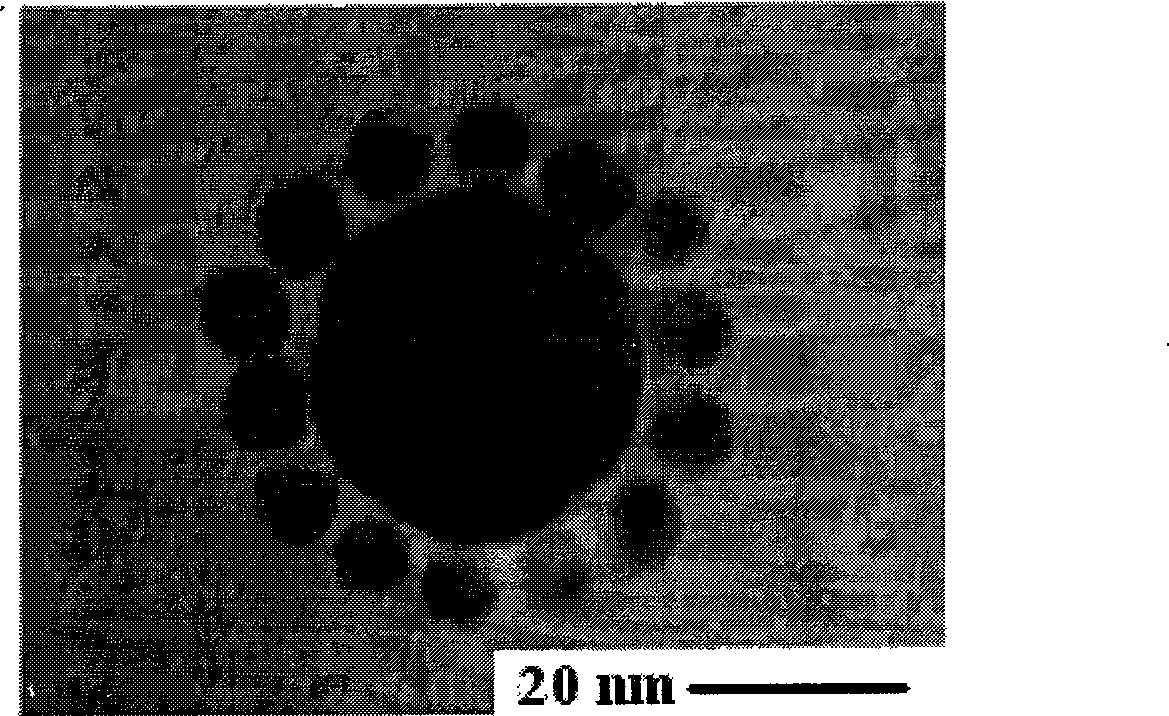

[0056] Transmission electron microscopy confirmed that the average particle size of the nanoparticles was 5nm.

Embodiment 2

[0058] The preparation method of gold nano sol is as follows:

[0059] (1) Use deionized water to make chloroauric acid into an aqueous solution with a concentration of 0.86mmol / L, then add methanol at -5°C to the chloroauric acid aqueous solution, and the volume ratio of chloroauric acid aqueous solution to methanol is 1:1.2, Ultrasound.

[0060] (2) Add an aqueous L-cysteine solution with a concentration of 0.0018g / ml to the chloroauric acid solution obtained in step 1, so that the molar ratio of L-cysteine to chloroauric acid is 1:2, and ultrasonically vibrate well mixed.

[0061] (3) Add dropwise a methanol solution of sodium borohydride with a concentration of 0.002g / ml to the above mixture, the molar ratio of sodium borohydride to chloroauric acid is 7:1, and ultrasonically vibrate to obtain a solution of S / Au with a ratio of 1:2. gold nanosol. Transmission electron microscopy confirmed that the average particle size of the nanoparticles was 10nm.

Embodiment 3

[0063] The preparation method of gold nano sol is as follows:

[0064] (1) Use deionized water to make chloroauric acid into an aqueous solution with a concentration of 0.6mmol / L, take 3mL of chloroauric acid solution in a conical flask, then add methanol at -1°C to the chloroauric acid aqueous solution, The volume ratio of acid aqueous solution to methanol is 1:1.4, and ultrasonically oscillated.

[0065] (2) Add an aqueous L-cysteine solution with a concentration of 0.0016 g / ml to the above chloroauric acid solution so that the molar ratio of L-cysteine to chloroauric acid is 1:2.5, and mix evenly by ultrasonic vibration.

[0066] (3) Add dropwise a methanol solution of sodium borohydride with a concentration of 0.002g / ml to the above mixture, the molar ratio of sodium borohydride to chloroauric acid is 6:1, and ultrasonically vibrate to obtain a solution of S / Au of 1:2.5. gold nanosol.

[0067] Transmission electron microscopy confirmed that the average particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com