Method for preparing reforming catalyst

A technology for reforming catalysts and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problems of catalyst performance degradation, carbon-containing catalysts, and cumbersome preparation methods and other issues, to achieve the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

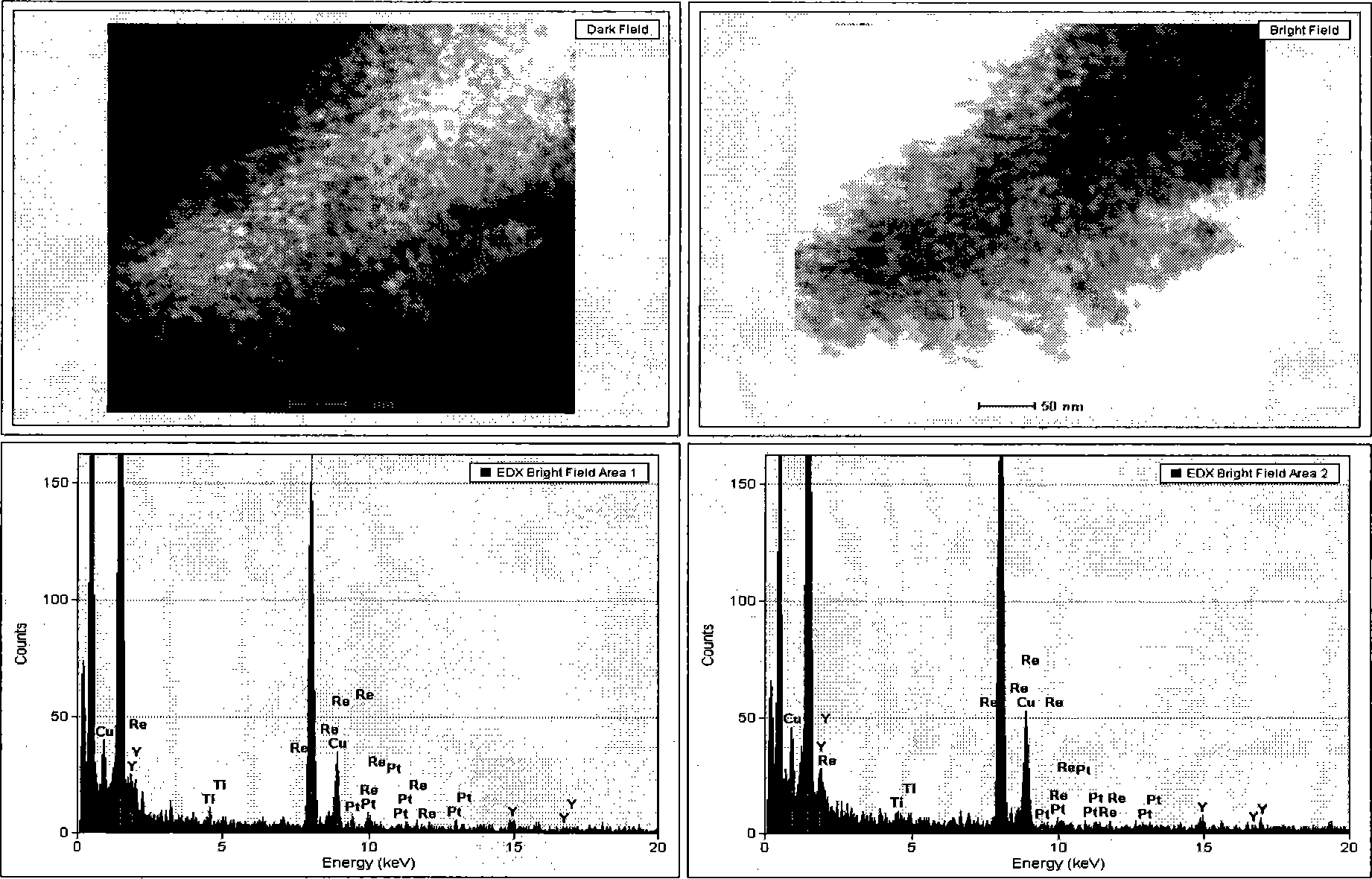

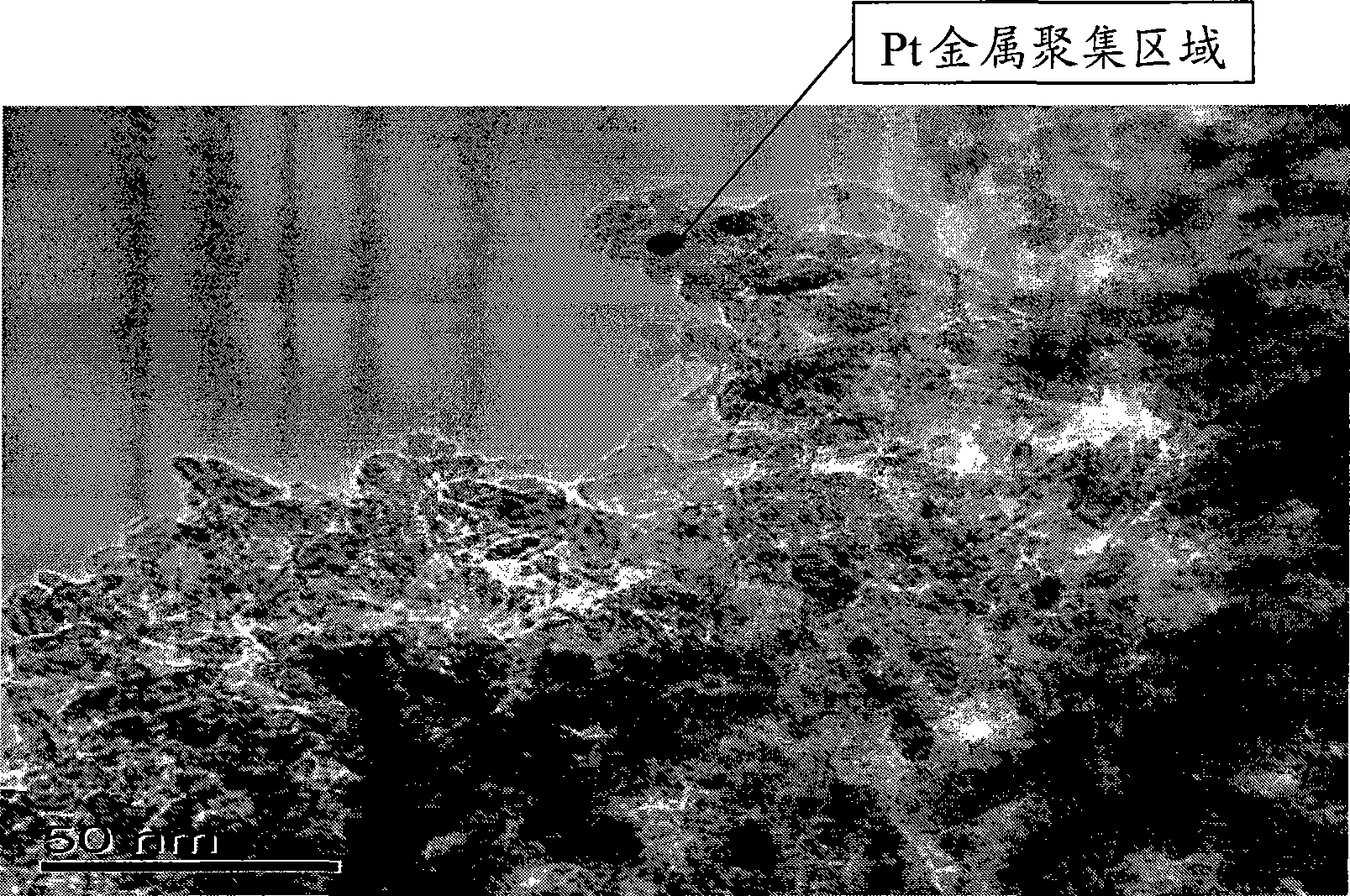

[0044] The catalyst was prepared by co-impregnation method.

[0045] Get 60 grams of bar-shaped γ-Al prepared with SB aluminum hydroxide powder (Germany Condea company production) 2 o 3 Carrier, make impregnating liquid with chloroplatinic acid, perrhenic acid, yttrium nitrate and hydrochloric acid, make impregnating liquid contain Pt 0.22%, Re 0.40%, Y 0.4%, Cl 1.8% (all relative to the quality of dry base alumina , the same below), add 0.5 g of citric acid, mix thoroughly, pour into a 500 ml flask, and reflux at 100° C. for 1 hour. γ-Al 2 o 3 The carrier was moved into the above impregnation solution with a liquid / solid volume ratio of 1.5, and was impregnated for 3 hours on a rotary vacuum evaporator (produced by Shanghai Yarong Biochemical Instrument Factory) at 30°C, 0.008MPa, and a rotational speed of 0.03 m / s. , the solid was dried under reduced pressure at 70°C, dried at 120°C for 12 hours, activated in dry air for 4 hours at 200°C, 500°C, and the gas / agent volume ...

example 2

[0048] Catalyst was prepared by the method of Example 1, except that 1.5 grams of citric acid was added in the impregnation solution, and the composition of the prepared catalyst B was shown in Table 1.

example 3

[0050] The catalyst was prepared by a stepwise impregnation method.

[0051] (1) Get 60 grams of bar-shaped γ-Al prepared from SB aluminum hydroxide powder (produced by Condea, Germany) 2 o 3 Carrier, make chloroplatinic acid and hydrochloric acid into impregnation solution, make the impregnation solution contain Pt 0.22%, Cl 1.8%, add 0.5 g of citric acid, mix well, pour into a 500 ml flask, and reflux at 100 ° C for 1 hour. γ-Al 2 o 3 The carrier was moved into the above-mentioned refluxed liquid with a liquid / solid volume ratio of 1.5, and was impregnated on a rotary vacuum evaporator at 30°C, 0.008MPa, and a rotational speed of 0.03 m / s for 3 hours, and made under reduced pressure at 70°C. The solid is dry, dried at 120°C for 12 hours, activated in dry air for 4 hours at 200°C, 500°C, and gas / agent volume ratio of 700 to obtain platinum-containing γ-Al 2 o 3 carrier.

[0052] (2) Prepare perrhenic acid, yttrium nitrate and appropriate amount of deionized water to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com