Bio-waste disposal method and apparatus

A technology of organic fertilizers and mixtures, applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, etc., can solve the problems of low content of active ingredients, difficult crop absorption, slow absorption and utilization process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

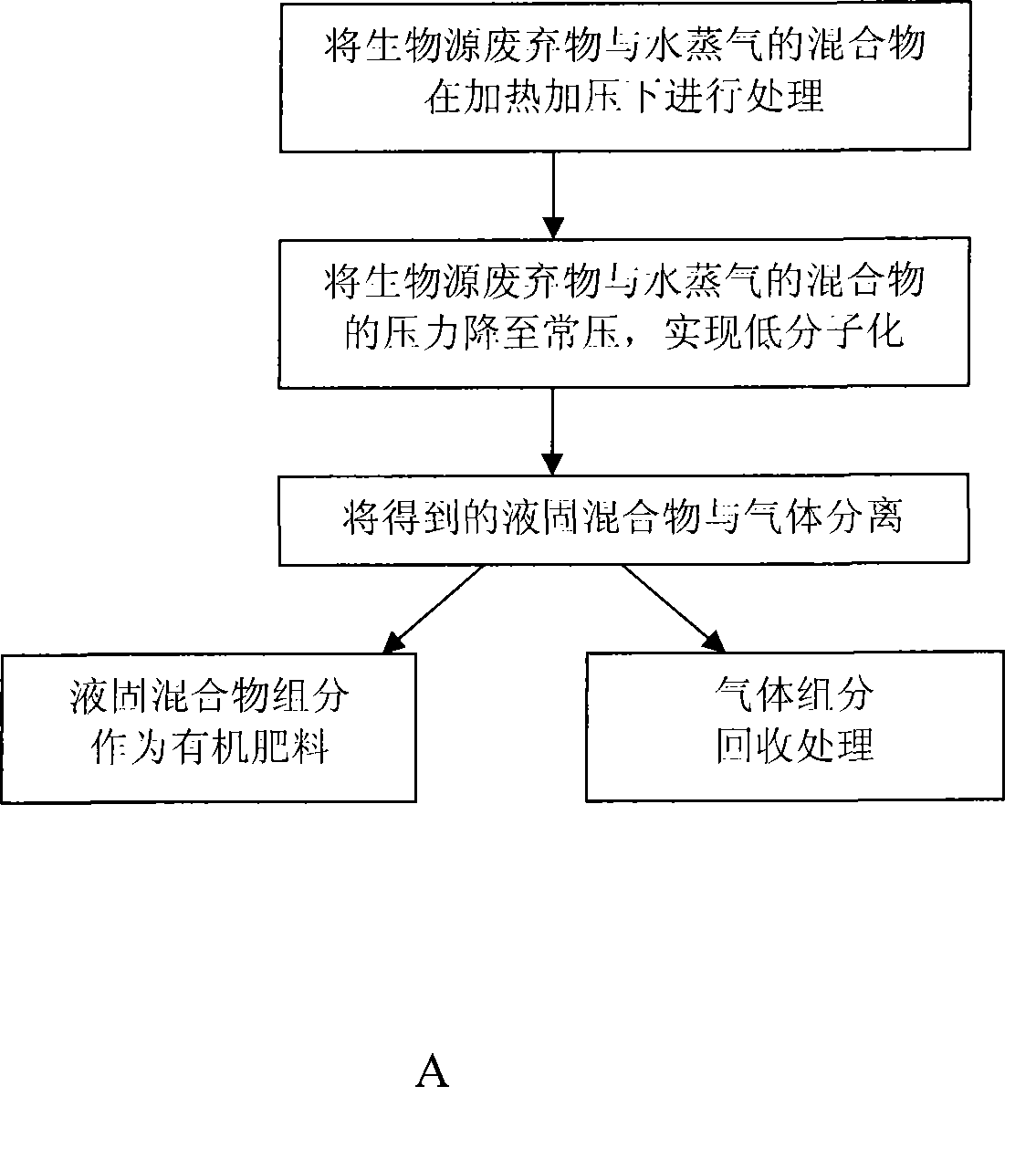

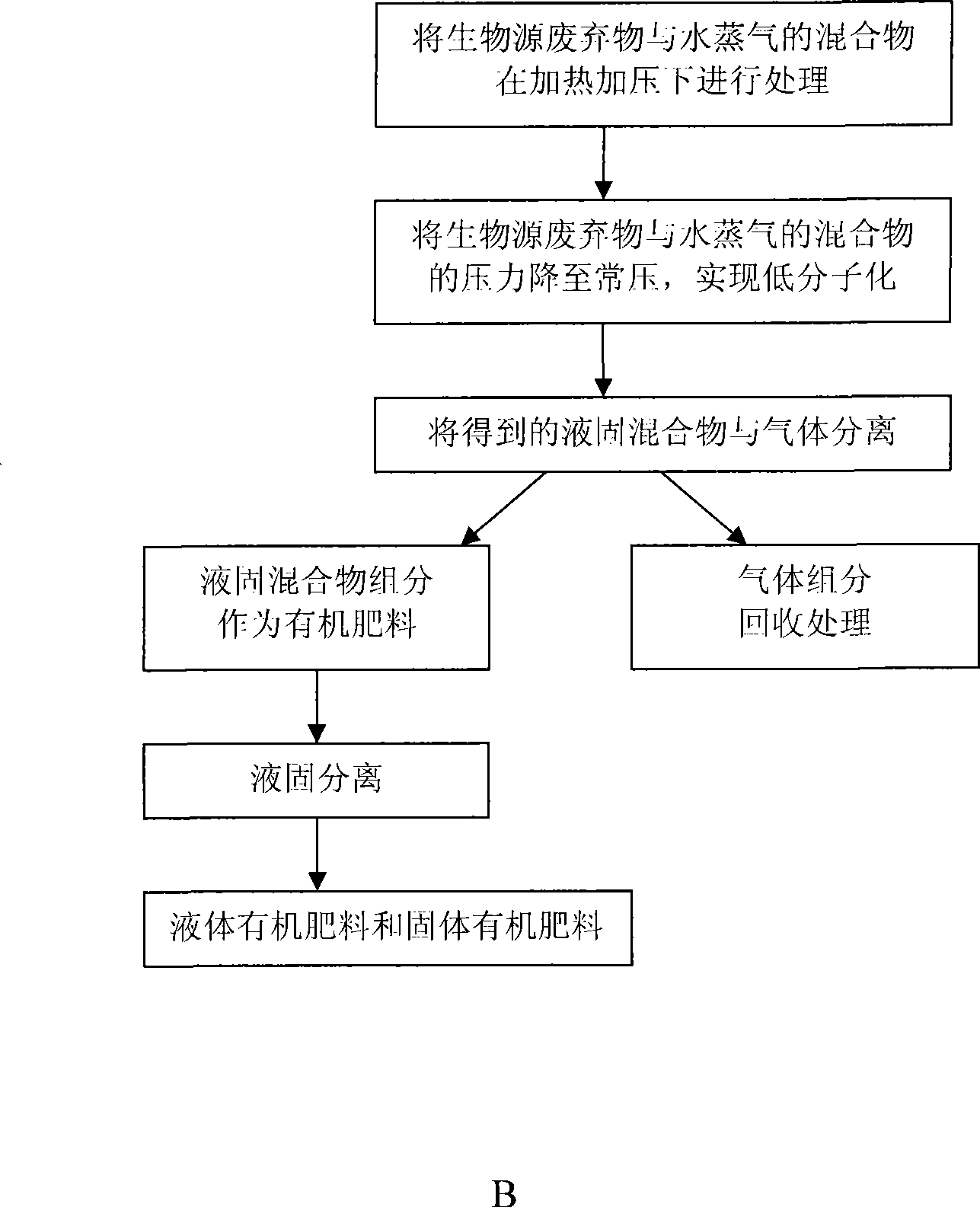

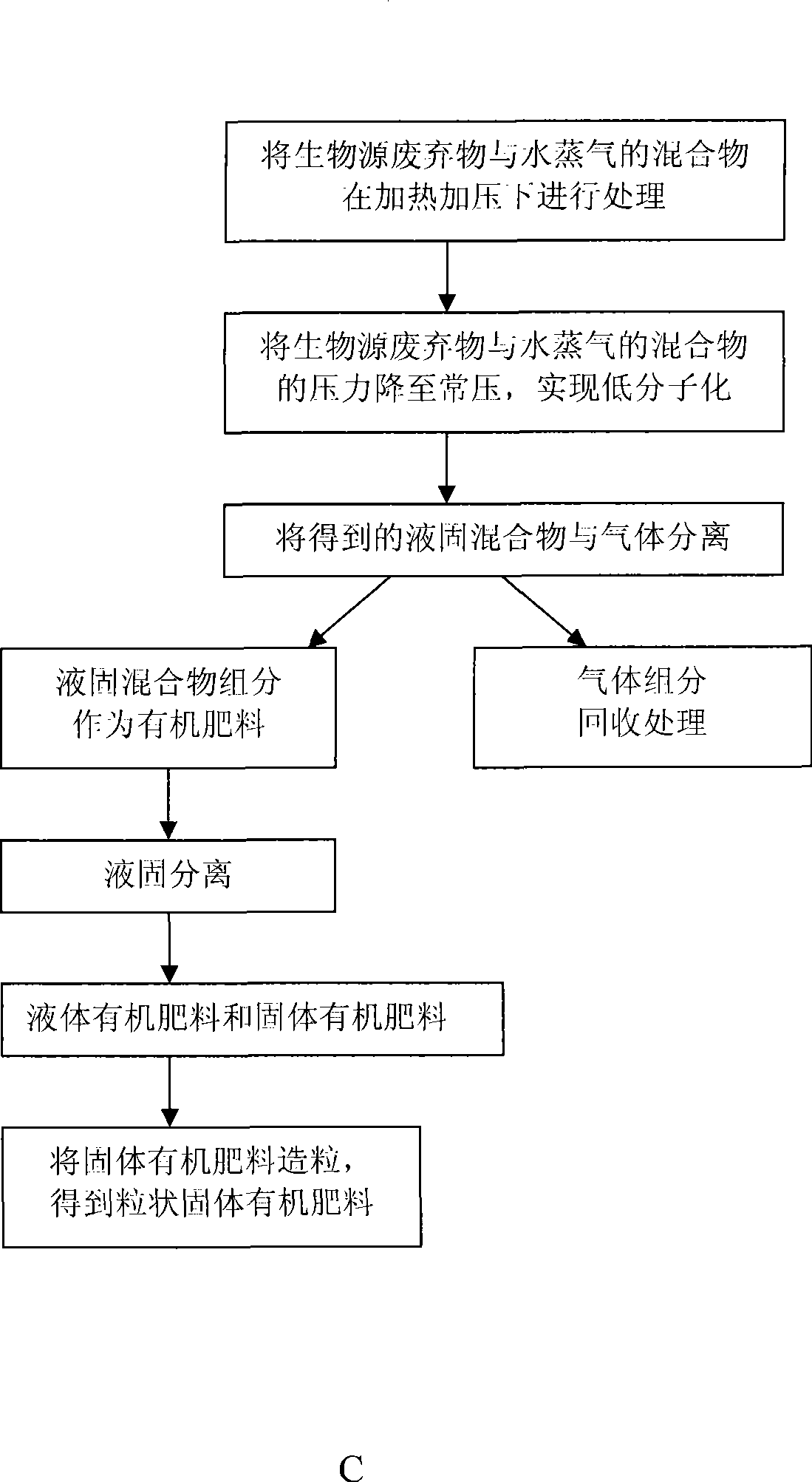

[0056] Such as figure 1 Shown in A, as the first embodiment of the organic fertilizer preparation method of the present invention, comprises the following steps:

[0057] Step 1: Treating the mixture of biological waste and water vapor under heating and pressure;

[0058] Step 2: reducing the pressure of the mixture of biological waste and water vapor in the heated and pressurized state to normal pressure, separating the obtained liquid-solid mixture from the gas, and obtaining a low-molecular liquid-solid mixture that can be used as an organic fertilizer.

[0059] In the above step 1, the heating temperature is 130-190° C.; the pressing pressure is 1.5-1.9 MPa and kept for 1-25 minutes. Preferably, the heating temperature is 135-170° C.; the pressurizing pressure is 1.5-1.75 MPa and kept for 5-20 minutes.

[0060] In said step 2, the shorter the time for reducing the pressure of the mixture of biological source waste and water vapor to normal pressure, the better. Depending...

Embodiment 1

[0105] Example 1 The following sewage sludge is used as raw material to prepare organic fertilizer

[0106] Take down 500kg of sewage sludge, mix it evenly with steam, make the temperature after mixing reach 170°C, and pressure reach 1.85MPa, and keep it for 22 minutes; reduce the pressure of the mixture of sewage sludge and steam to normal within 45 seconds Press to reduce the molecular weight of sewage sludge and obtain a liquid-solid mixture that can be used as an organic fertilizer.

[0107] Table 4 shows the content of various components in the liquid-solid mixture obtained after the sewage sludge is treated by the method of the present invention.

[0108] Table 4

[0109] Analysis Project Content of various ingredients (wt%) Various oligosaccharides >8 Various amino acids, small molecule peptides >10 organic acid 0.40 N 3.60 P 2 o 5 2.78 K 2 o 0.94 CaO 0.18 MgO 0.08 moisture content 50.0

[0110...

Embodiment 2

[0118] Example 2 Preparation of liquid organic fertilizer with bamboo leaves as raw material

[0119] Take 350kg of bamboo leaves, mix it evenly with steam, make the temperature after mixing reach 138°C, and pressure reach 1.45MPa, and keep it for 1 minute; reduce the pressure of the above mixture and steam mixture to normal pressure within 35 seconds, The molecular weight of the mixture is reduced; the obtained product is centrifuged to obtain liquid organic fertilizer.

[0120] Table 7

[0121]

[0122] Table 7 shows the percentage by weight of various components in the liquid organic fertilizer obtained after bamboo leaves are processed by the method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com