Brass alloy material and preparation thereof

A brass alloy and alloy technology, applied in the field of brass alloy materials and their preparation, can solve the problems of low tensile strength and complex composition, and achieve the effects of high tensile strength, simple composition and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to the preparation method of the brass alloy material provided by the present invention, the copper, zinc, aluminum and bismuth can be various raw materials conventionally used in this field, for example, the copper can be various electrolytic copper. The order of adding copper, zinc, aluminum and bismuth can be determined according to the melting point of the added elements and the order and amount of volatile and easy oxidation. In the present invention, the order of adding copper, zinc, aluminum and bismuth is as follows: Electrolytic copper is added first, then zinc is added, and bismuth and aluminum are added last, and casting is performed within 2 minutes after the copper, zinc, aluminum and bismuth are smelted evenly.

[0028] The smelting method preferably includes smelting the alloy raw material into a uniform liquid mixture, and then casting the liquid mixture into shape, wherein the smelting equipment can be a vacuum arc melting furnace, a vacuum ind...

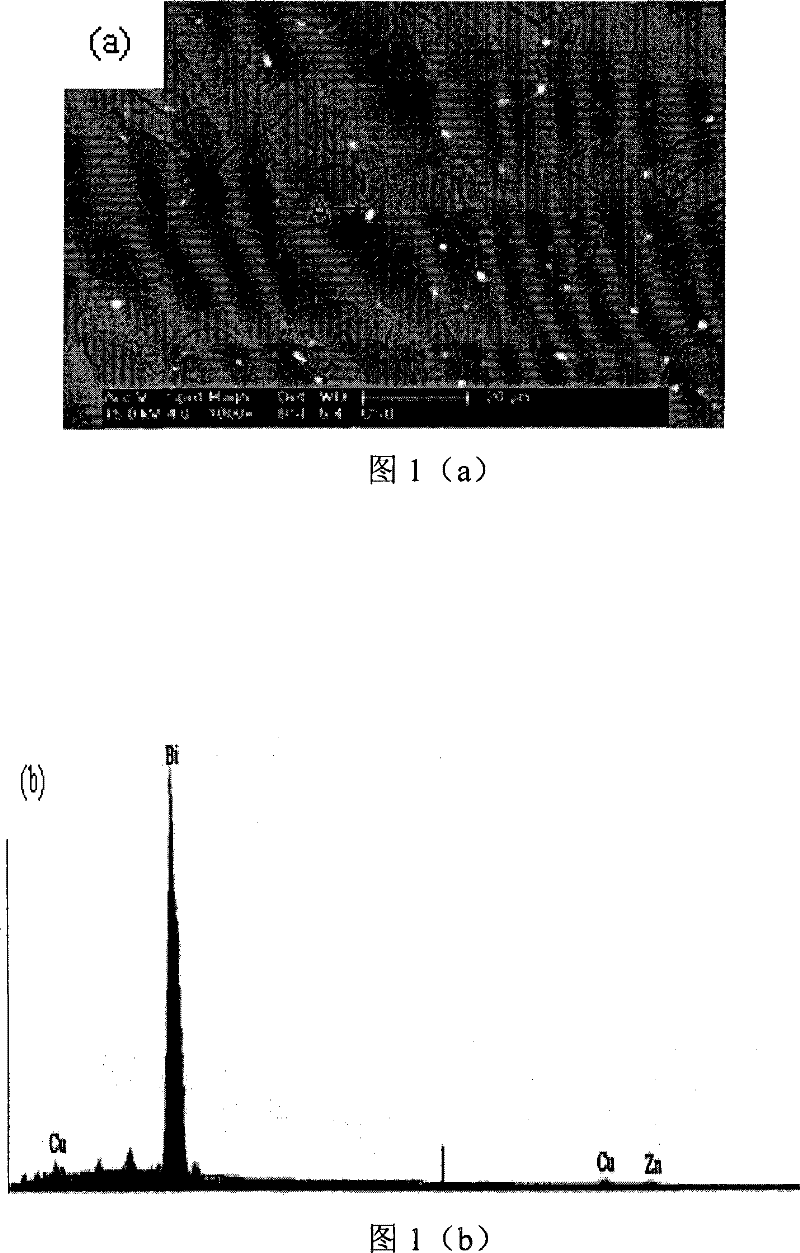

Embodiment 1

[0036] This embodiment is used to illustrate the brass alloy material provided by the present invention and its preparation method.

[0037] (1) Smelting and casting molding: 885 grams of No. 2 electrolytic copper, 592.5 grams of zinc, 15 grams of bismuth, 7.5 grams of aluminum and charcoal with a purity of 99.99% by weight are first No. 2 electrolytic copper and charcoal, then zinc, and then bismuth Put them into the vacuum arc melting furnace in the order of aluminum and smelting at 1700 ° C. After the alloy is fully melted and stirred evenly, quickly add it to the casting mold preheated to 300 ° C in advance. The melting time is 3 minutes and the pouring time is 3 minutes. Minutes, the furnace temperature is 1100 ° C, air-cooled demoulding, to obtain a Φ50 mm ingot. The composition of the ingot was 59% by weight of copper, 39.5% by weight of zinc, 1% by weight of bismuth and 0.5% by weight of aluminum.

[0038] (2) Hot extrusion: Preheat the Φ50mm ingot obtained in (1) abo...

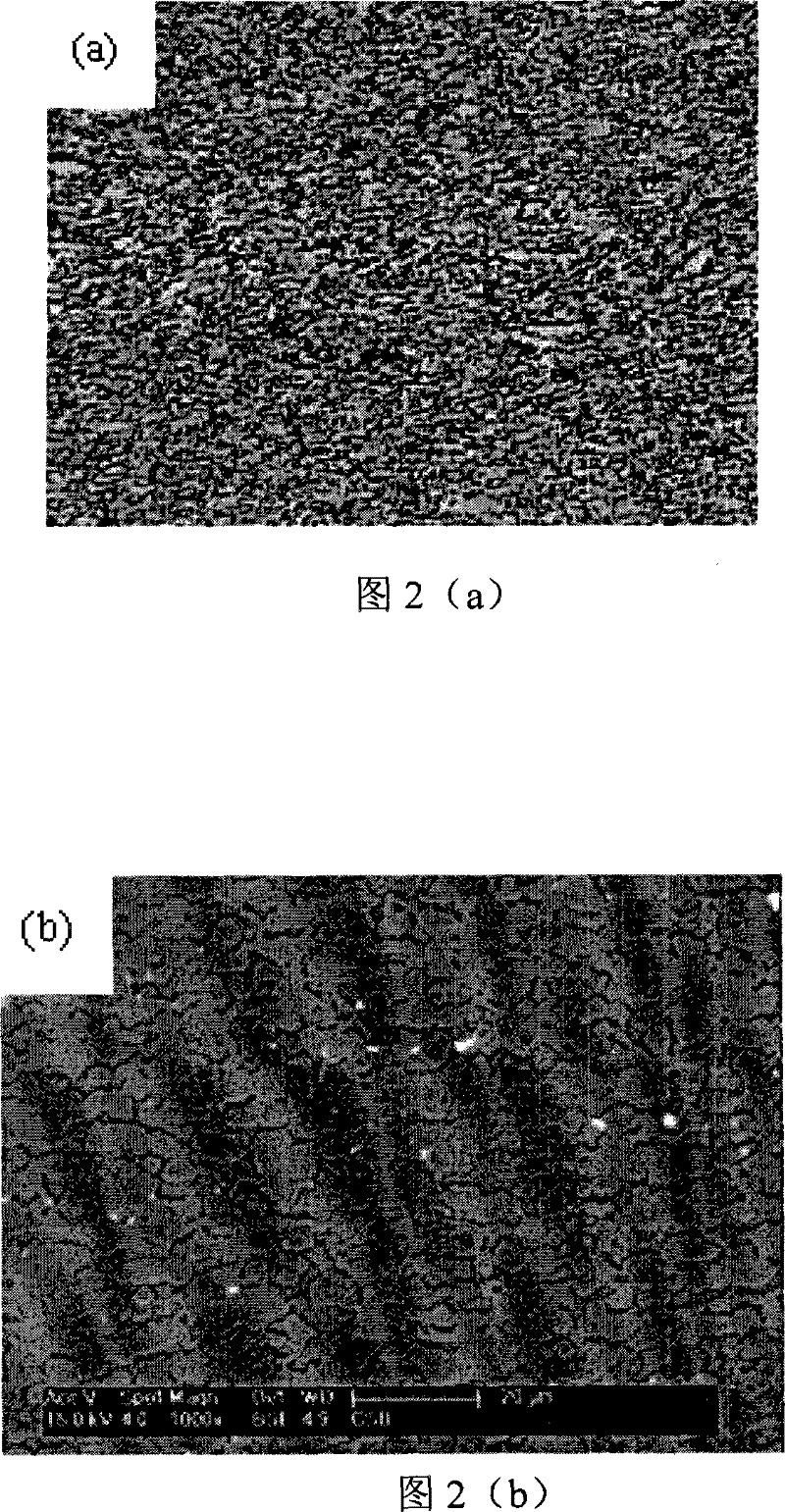

Embodiment 2

[0048] This embodiment is used to illustrate the brass alloy material provided by the present invention and its preparation method.

[0049] The brass alloy material was prepared according to the method described in Example 1, except that the obtained extruded rod was not subjected to the recrystallization annealing step to obtain the brass alloy material sample S2 provided by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com