Sputtering equipment with close packing tip anode

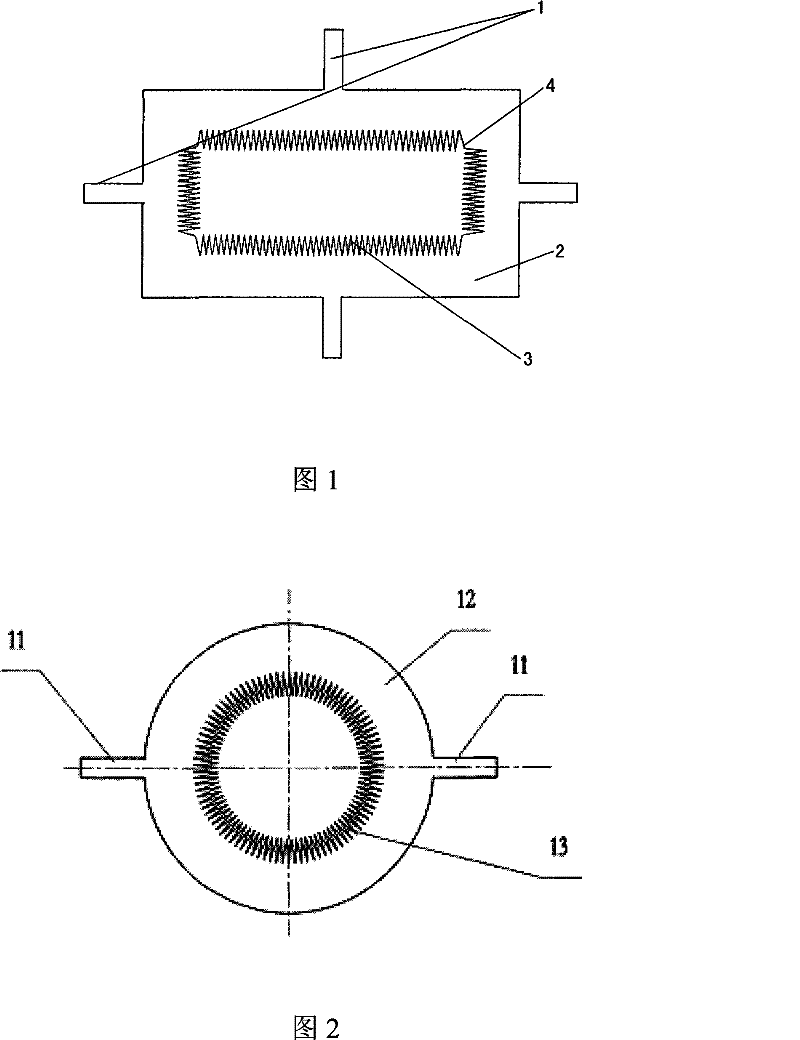

A sputtering equipment and cutting-edge technology are applied in the field of sputtering equipment with close-packed tip anodes, which can solve the problems of limited material preparation cost, negative oxygen ion bombardment, low sputtering efficiency, etc., so as to eliminate the impact of negative oxygen ion bombardment. , the effect of increasing surface area, meeting speed and process window requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

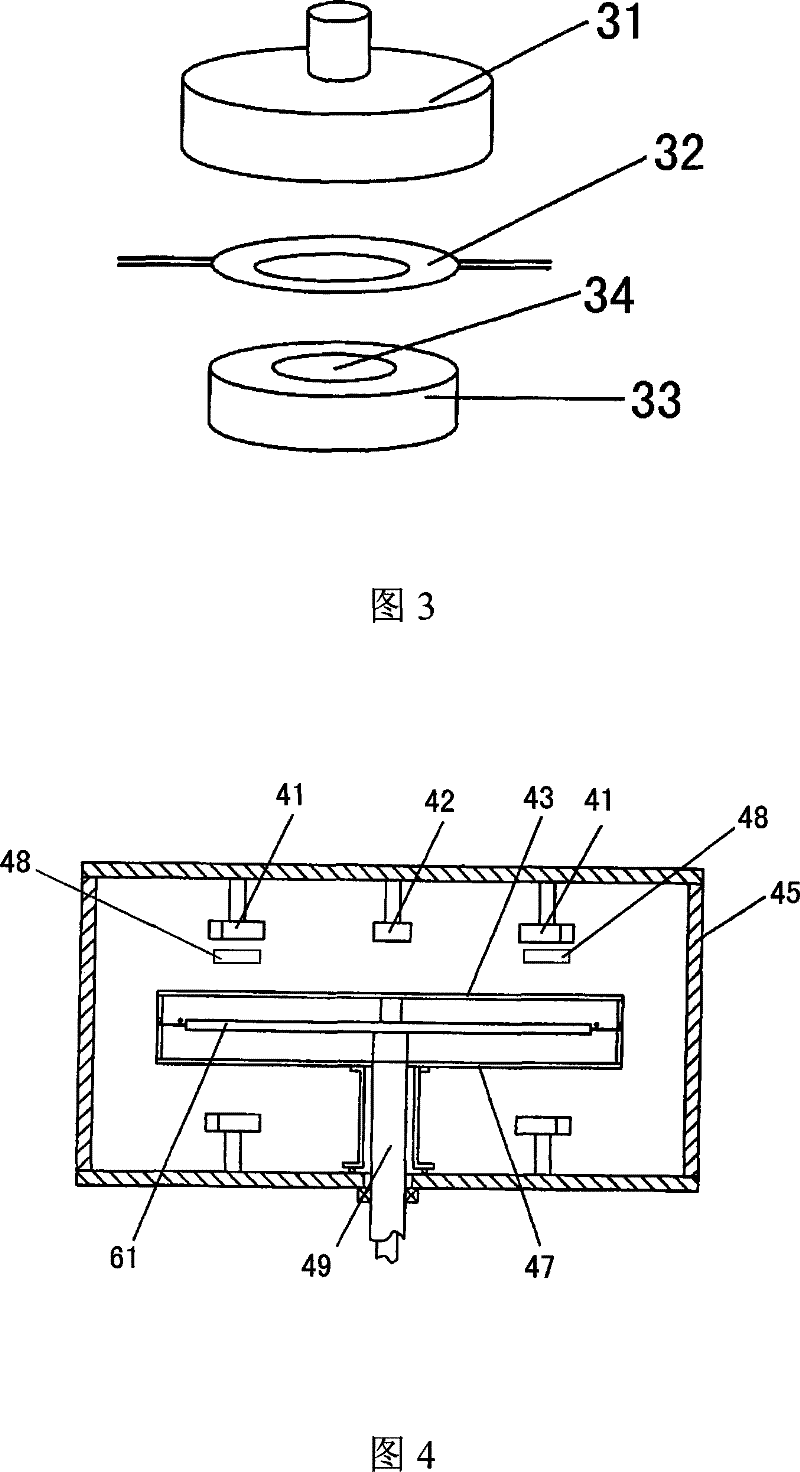

[0030] Such as image 3As shown, Example 1 is a schematic diagram of preparing YBCO high temperature superconducting thin film by static sputtering. Carry out sputtering with the circular YBCO planar target material 31 of φ 68mm, place the close-packed tip anode 32 of circular YBCO sputtering target material at about 20 mm below the planar target material 31 (in image 3 , the close-packed tip body in the close-packed tip anode 32 is not shown and omitted). Opposite to the close-packed tip anode 32 are the oxide single crystal substrate 34 and the heating body 33 of φ 2 ". Generally, a layer of soaking quartz sheet (not shown in the figure) is added between the heating body 33 and the oxide single crystal substrate 34. Shown), in order to play the role of heat uniformity and prevent the sample from bursting due to uneven heating. A positive bias voltage of 50V is applied to the anode end of the close-packed tip.

[0031] During the implementation, at 860°C heating temperatur...

Embodiment 2

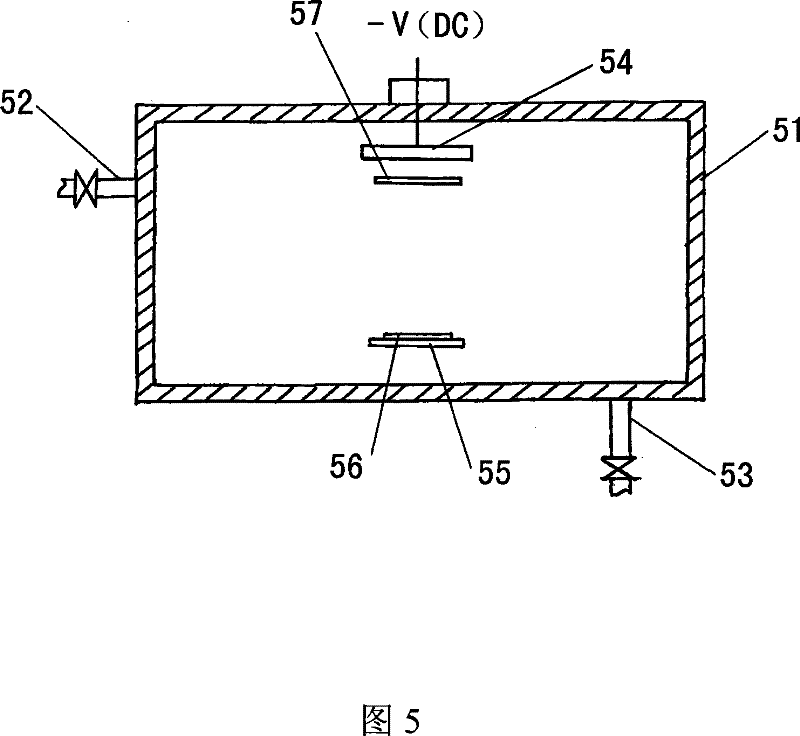

[0034] YBCO high temperature superconducting thin films were prepared by dynamic fixed axis rotation. The equipment disclosed in the patent No. 200620119334.1 entitled "A Device for Batch Preparation of Double-sided High-Temperature Superconducting Thin Films" can be used, such as Figure 4 As shown, the equipment is provided with a planar high-temperature superconducting material target 41 and a metal target 42 for in-situ sputtering electrodes in the vacuum chamber 45; A rotating device, the disc-shaped heating rotating device is composed of a disc rotating device and a disc heating device. The disc heating device includes an upper heating plate 43 and a lower heating plate 47; the disc rotating device is composed of a disc sample stage 61 and a rotating device, and the disc sample stage 61 is evenly spaced for placing large-area superconducting thin films. The circular hole of the substrate (not shown in the figure), the rotating device includes the main rotating shaft 49,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com