Industrial furnace liner

A technology for industrial furnaces and furnace linings, applied in lining support, overall lining and other directions, can solve the problems of reduced furnace sealing and heat preservation, large heat dissipation loss on the surface of the furnace body, and large heat storage loss in the masonry, so as to shorten the furnace laying cycle. , The effect of improving working conditions and simplifying the structure of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

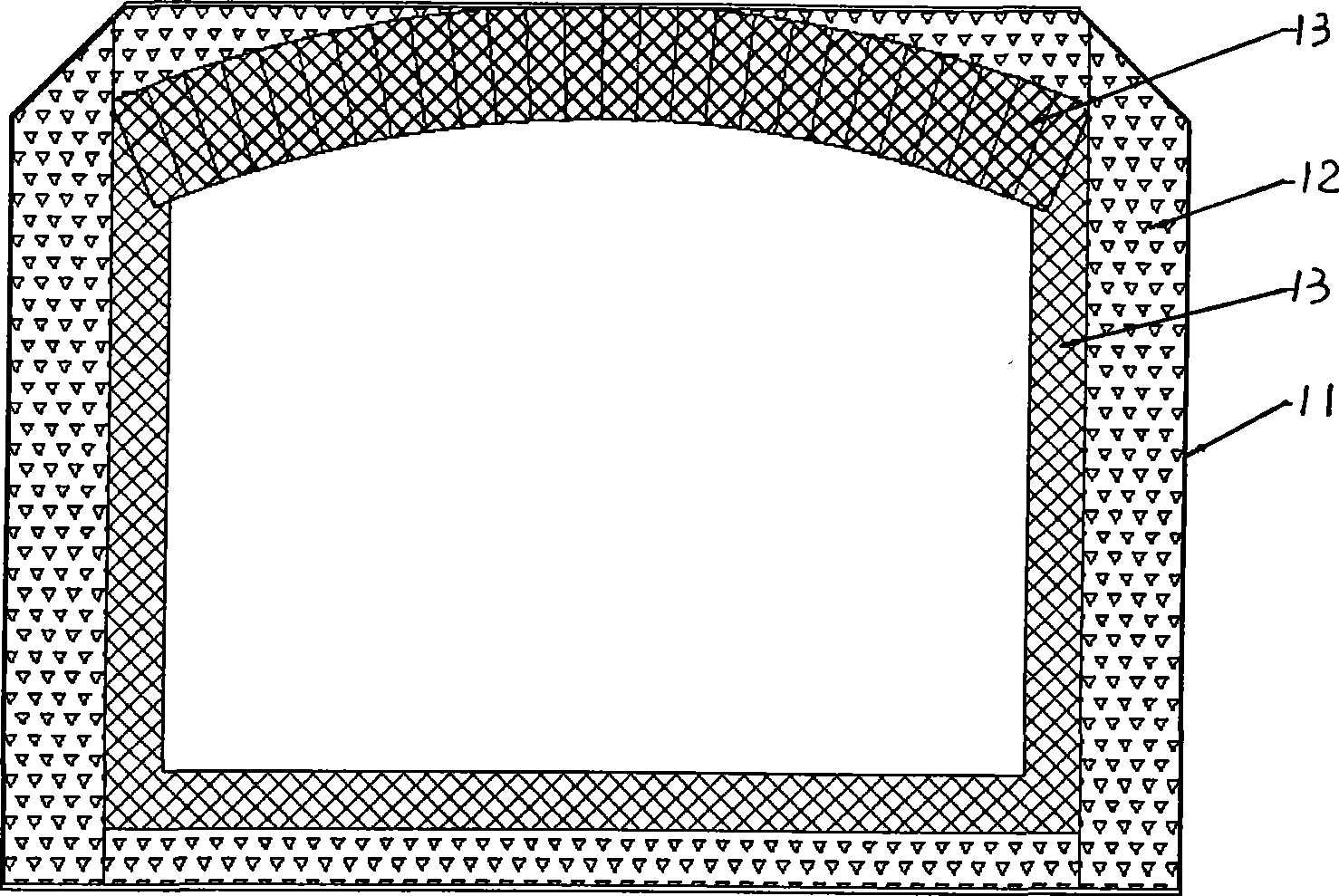

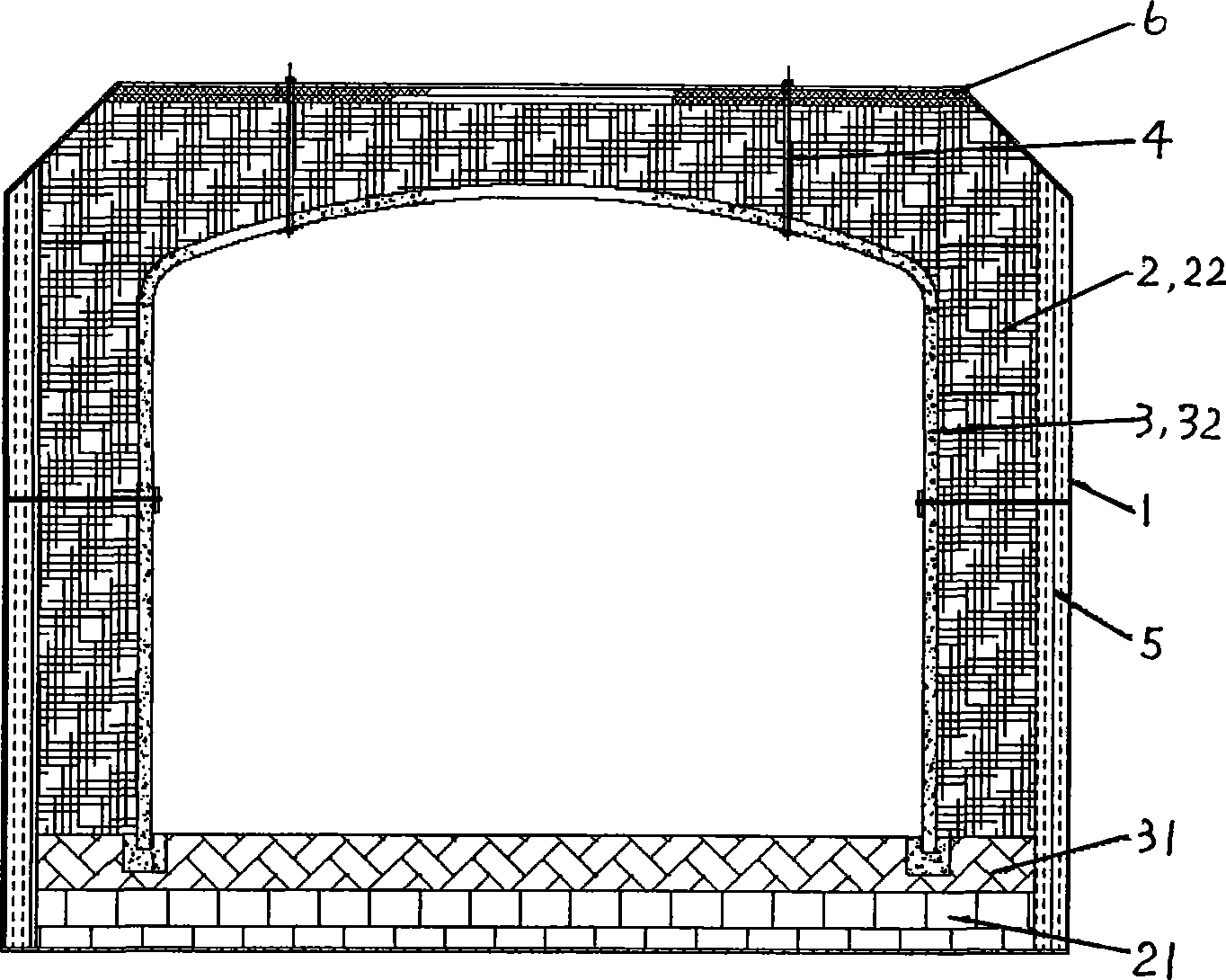

[0020] see figure 2 , image 3 , The industrial furnace lining of the present invention is arranged in the furnace shell 1 of the industrial furnace, and includes an inner high temperature resistant layer 3 and an outer heat insulating layer 2 .

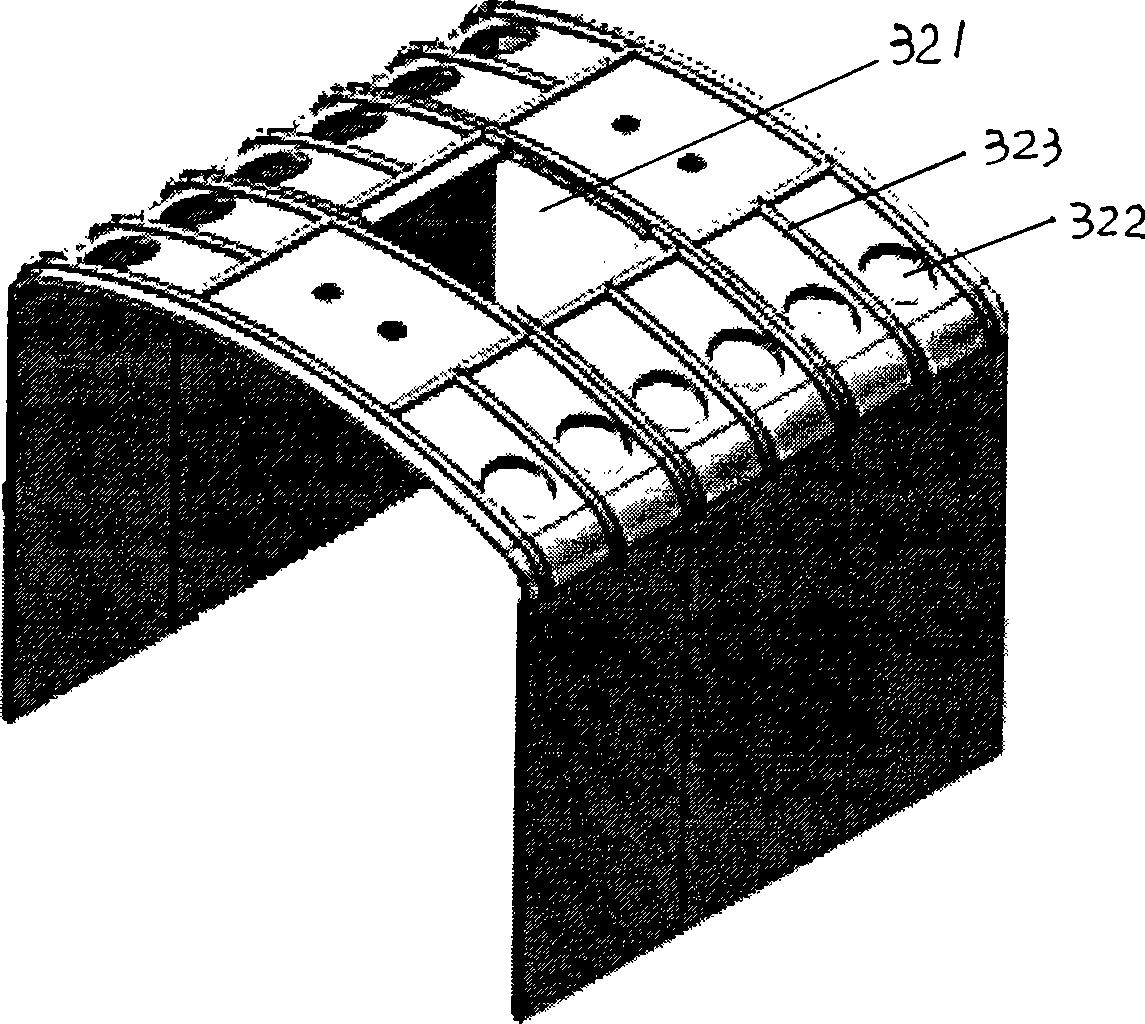

[0021] Cooperate see image 3 , the inner layer high temperature resistant layer 3 comprises the bottom 31 that is built by impermeable bricks, and the lining 32 that is arranged on both sides and top, and this lining 32 is to adopt high temperature resistant non-metallic composite material (this embodiment is silicon carbide / Silicon nitride composite material) made of an integral inverted U-shaped structural member. Both sides of the inner lining 32 of the inverted U-shaped structural member are plate structures, and an air hole 321 is provided in the middle of the top for communicating with the outside world. Rib structure 323 . The inner lining 32 of the inverted U-shaped structure is fixedly connected with the furnace shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com