Industrial refining production method of rice bran oil and equipment thereof

A production method and technology of rice bran oil, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems such as difficult to remove the color, difficult to meet the refining requirements of rice bran oil, and the influence of the color of the refining rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

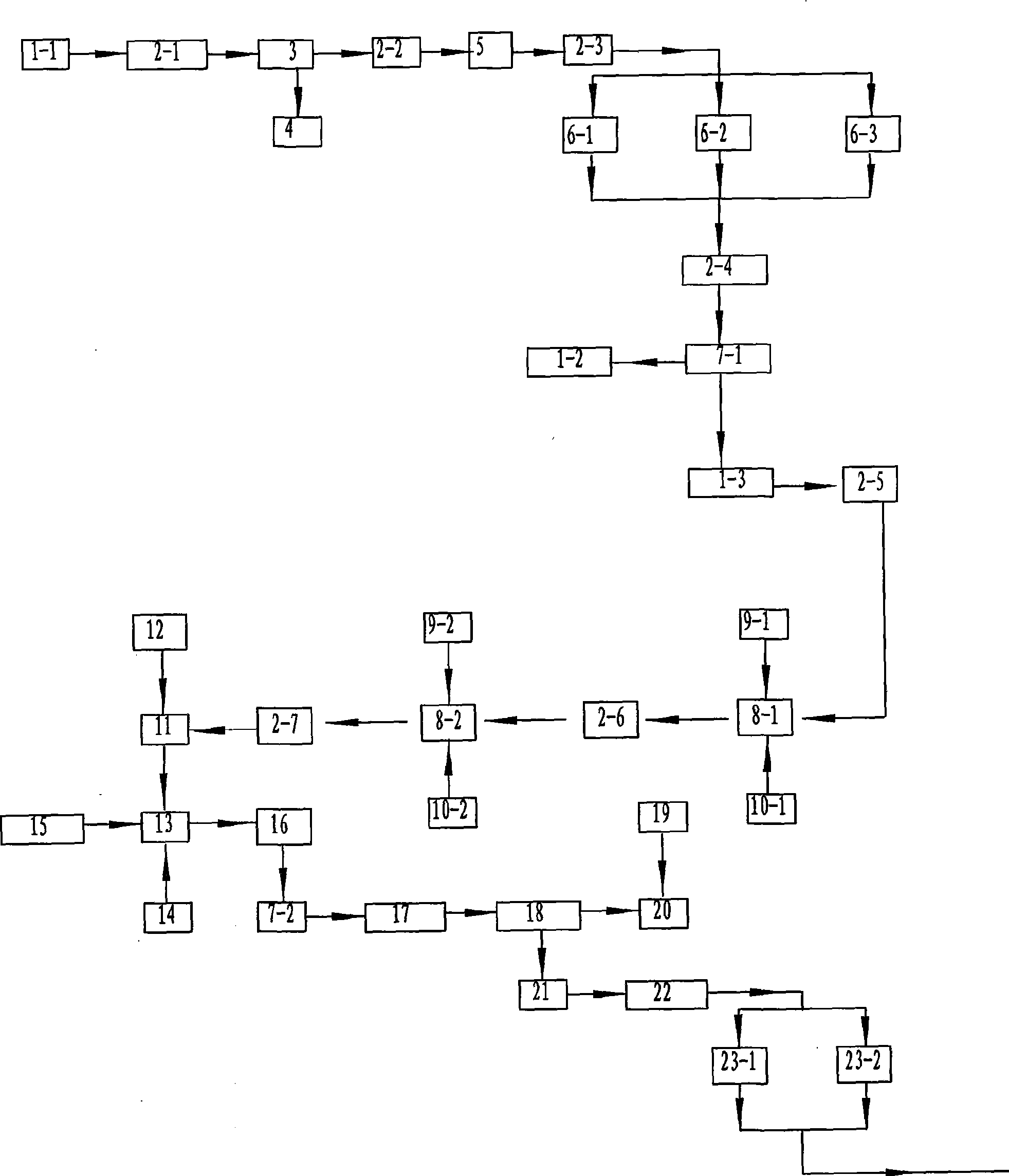

[0005] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0006] Shown in accompanying drawing, the present invention is realized by the following steps:

[0007] 1. Hydration degumming: heat rice bran crude oil (hereinafter referred to as crude oil) to 75°C, stir at a speed of 60r / min, and add 80°C hot water at the same time, the amount of water added is phospholipid (phospholipid is contained in crude oil, it It dissolves and disperses in crude oil in the form of phospholipid internal salt structure. When the water content increases, it absorbs water and swells, increases in volume, and precipitates from the oil in the form of colloid. And know) 2-3 times of the content, add in 5-10 minutes speed, stir, rotating speed 60r / min stirring, when phospholipid precipitates, stop stirring, stand still for 4 hours to precipitate, phospholipid precipitation completes oil-water layering Afterw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com