Method for preparing hydroxylapatite-silk fibroin compound stent material using two-step method

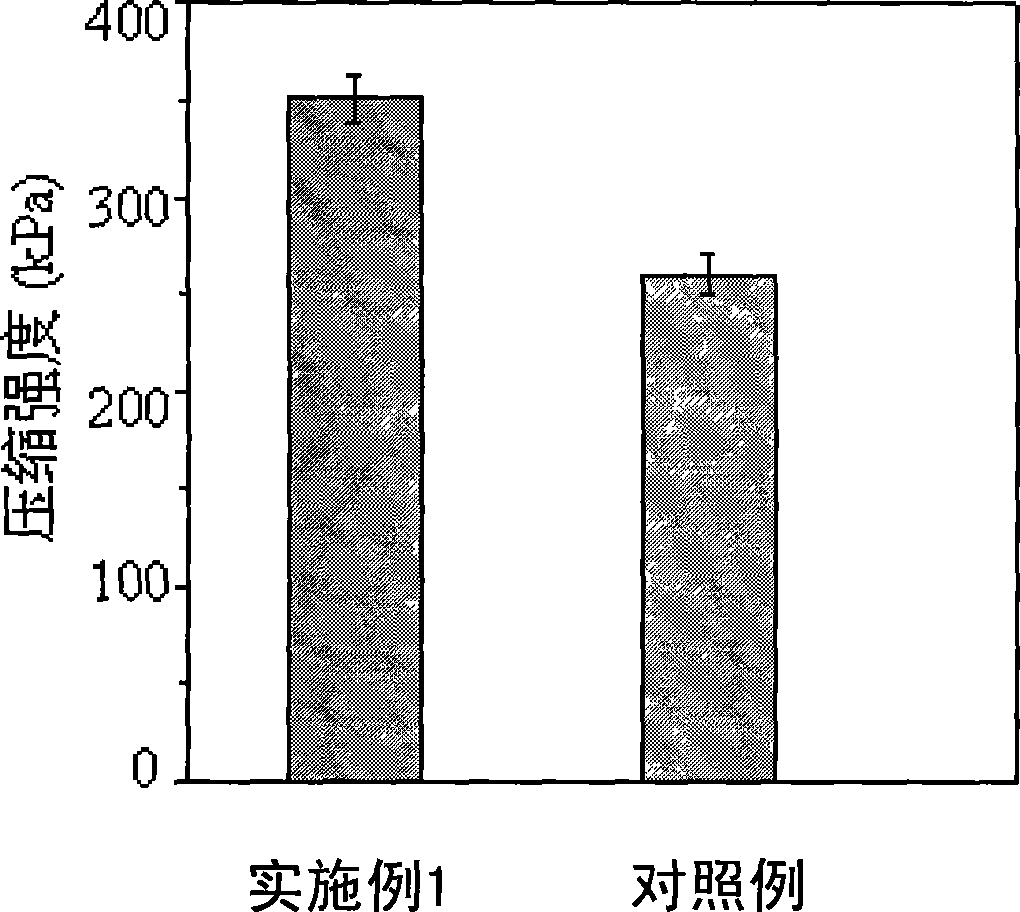

A technology of hydroxyapatite and silk fibroin, which is applied in medical science, prosthesis, etc., can solve the problems of poor interfacial bonding force, easy damage of interfacial layer, loss of effective strength, etc., and achieve the effect of good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

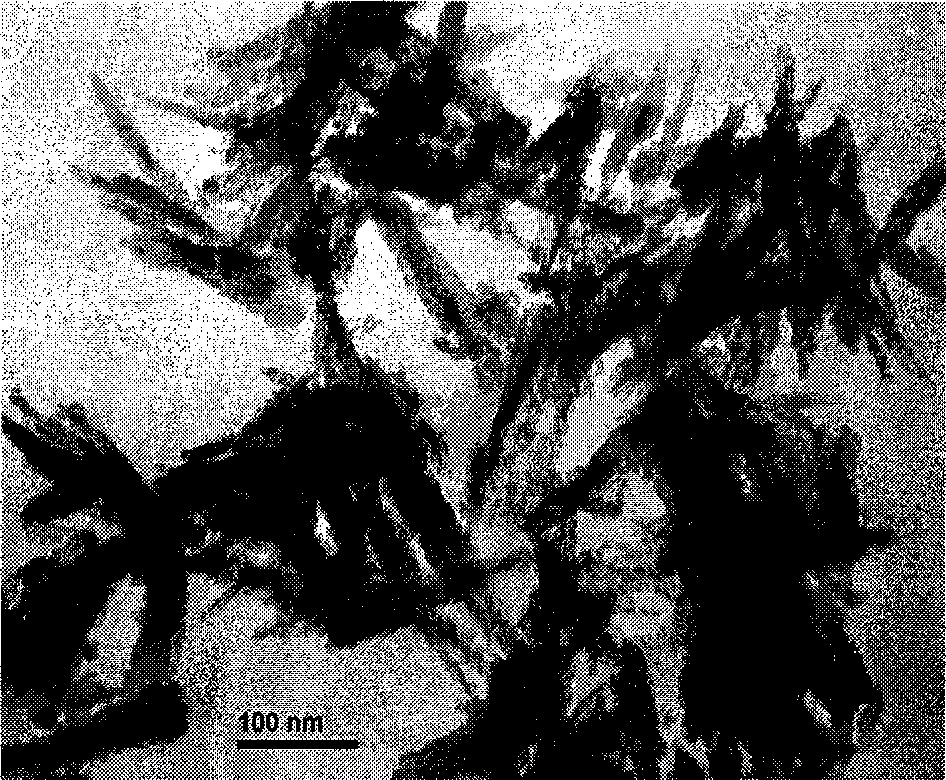

[0019] (1) Add 100 mL of CaCl with a concentration of 0.25 mol / L dropwise in the silk fibroin protein solution of 10 mL with a concentration of 2.5% (w / v) 2 solution and 100 mL of NaH with a concentration of 0.15 mol / L 2 PO 4 The solution was stirred continuously, and the pH value of the solution was adjusted to be 9 during the reaction. After the dropwise addition, the reaction liquid was aged for 24 hours, washed and centrifuged (8000rpm, 5min) three times to obtain hydroxyapatite-silk fibroin composite mud;

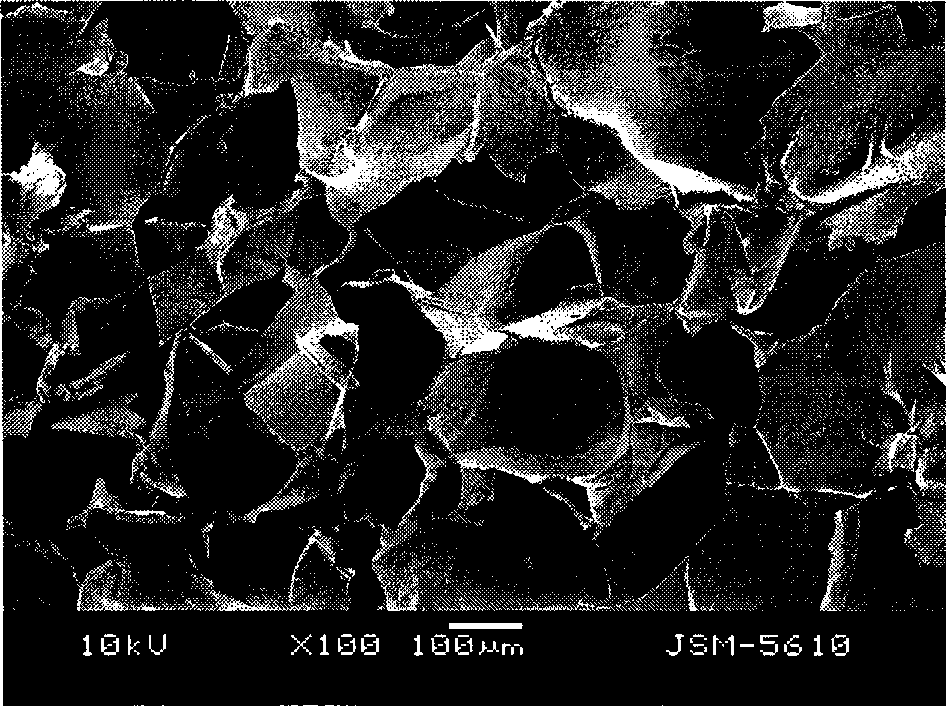

[0020] (2) Add silkworm silk fibroin protein solution with a concentration of 5% (w / v) to the hydroxyapatite-silk fibroin composite mud and keep stirring. The mass ratio of the dry weight of the composite mud to silk fibroin is 4:1 , adjust the pH value to 9; after stirring for 20 to 30 minutes, pour the mixture into the mold, pre-freeze at -20°C for 12 hours, freeze at -80°C for 2 hours, and freeze-dry to prepare a porous hydroxyapatite-silk fibroin composite scaffo...

Embodiment 2

[0022] (1) Add 100 mL of 0.25 mol / L Ca(NO 3 ) 2 solution and 100 mL of Na with a concentration of 0.15 mol / L 2 HPO 4 The solution was stirred continuously, and the pH value of the solution was adjusted to be 9 during the reaction. After the dropwise addition, the reaction liquid was aged for 24 hours, washed and centrifuged (8000rpm, 5min) three times to obtain hydroxyapatite-silk fibroin composite mud;

[0023] (2) Add silkworm silk fibroin solution with a concentration of 2% (w / v) to the hydroxyapatite-silk fibroin composite mud and keep stirring. The mass ratio of the dry weight of the composite mud to silk fibroin is 4:1 , adjust the pH value to 9; after stirring for 20 to 30 minutes, pour the mixture into the mold, pre-freeze at -20°C for 12 hours, freeze at -80°C for 2 hours, and freeze-dry to prepare a porous hydroxyapatite-silk fibroin composite scaffold Material.

Embodiment 3

[0025] (1) Add 100 mL of 0.25 mol / L Ca(NO 3 ) 2 solution and 100 mL of K with a concentration of 0.15 mol / L 2 HPO 4 The solution was stirred continuously, and the pH value of the solution was adjusted to be 9 during the reaction. After the dropwise addition, the reaction liquid was aged for 24 hours, washed and centrifuged (8000rpm, 5min) three times to obtain hydroxyapatite-silk fibroin composite mud;

[0026] (2) Add silkworm silk fibroin solution with a concentration of 8% (w / v) to the hydroxyapatite-silk fibroin composite mud and keep stirring, the mass ratio of the dry weight of the composite mud to silk fibroin is 4:1 , adjust the pH value to 9; after stirring for 20 to 30 minutes, pour the mixture into the mold, pre-freeze at -20°C for 12 hours, freeze at -80°C for 2 hours, and freeze-dry to prepare a porous hydroxyapatite-silk fibroin composite scaffold Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com