Preparation of rare earth doping fluorescent functional mesoporous material

A rare earth doped, mesoporous material technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, silicon oxide, etc., can solve the problem of the decrease of the loading rate of the pore channels, and achieve the effect of good luminescence performance, simple method and high-efficiency loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

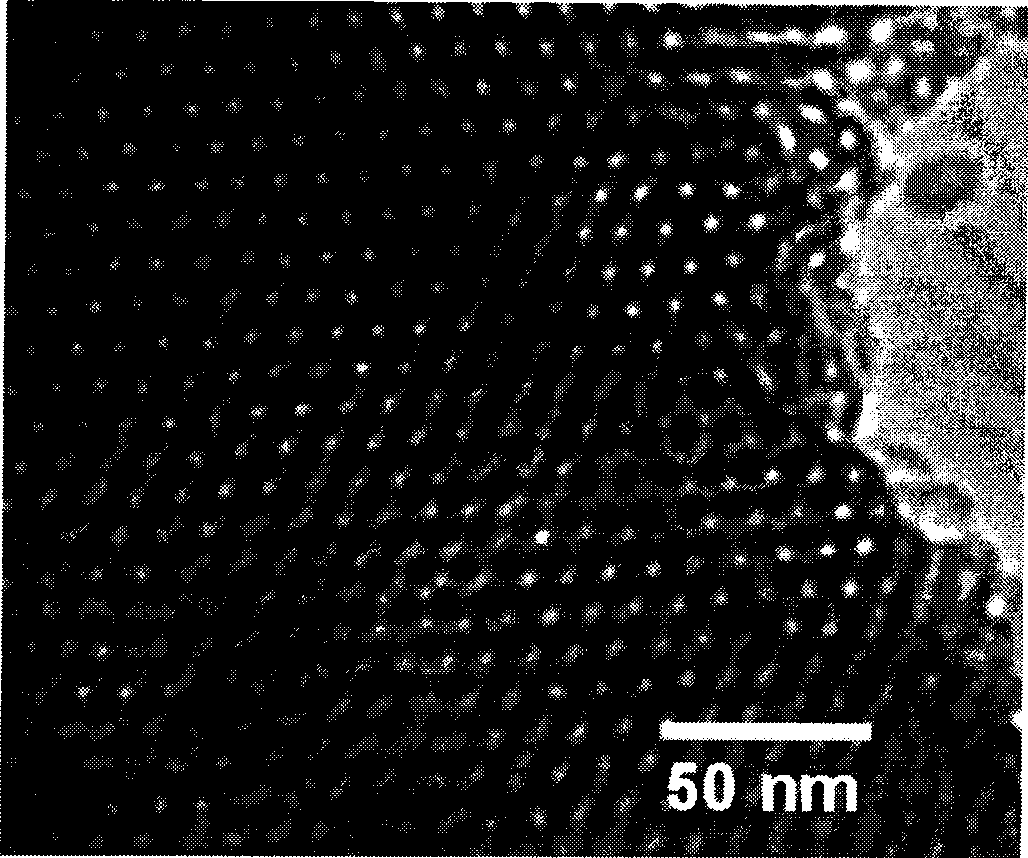

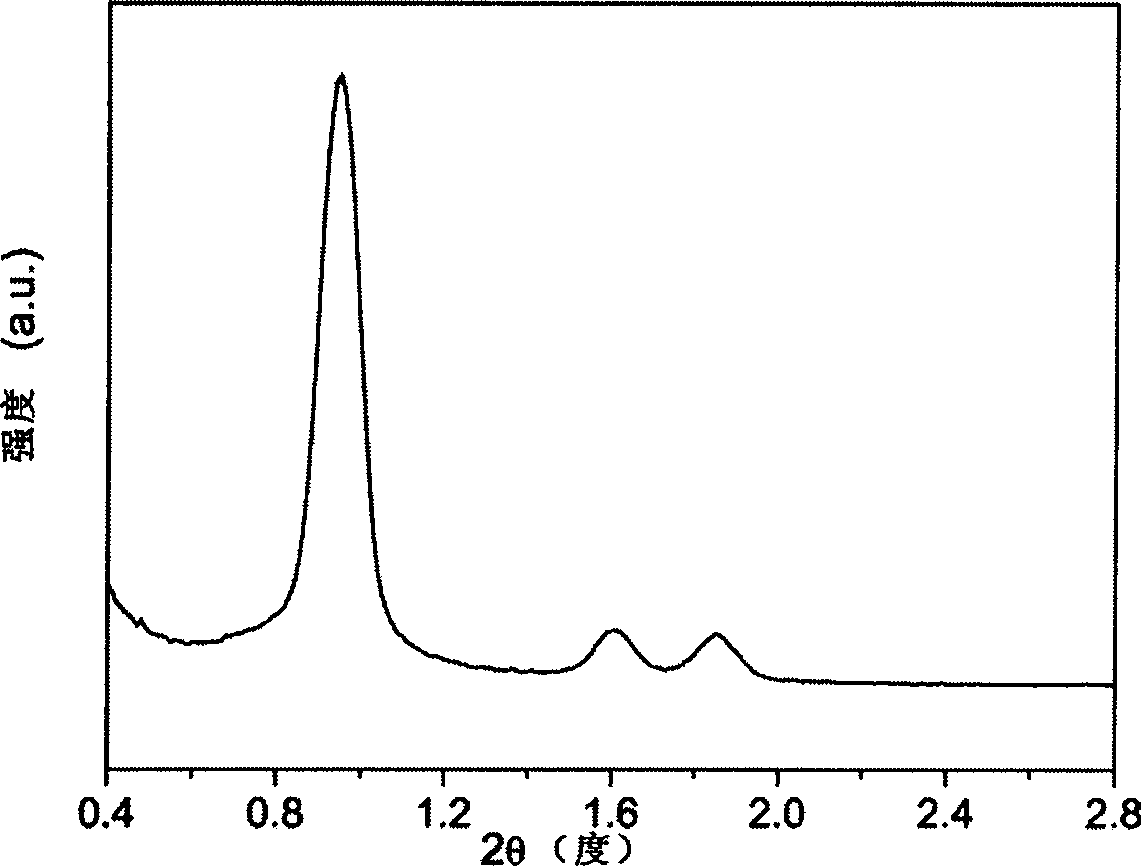

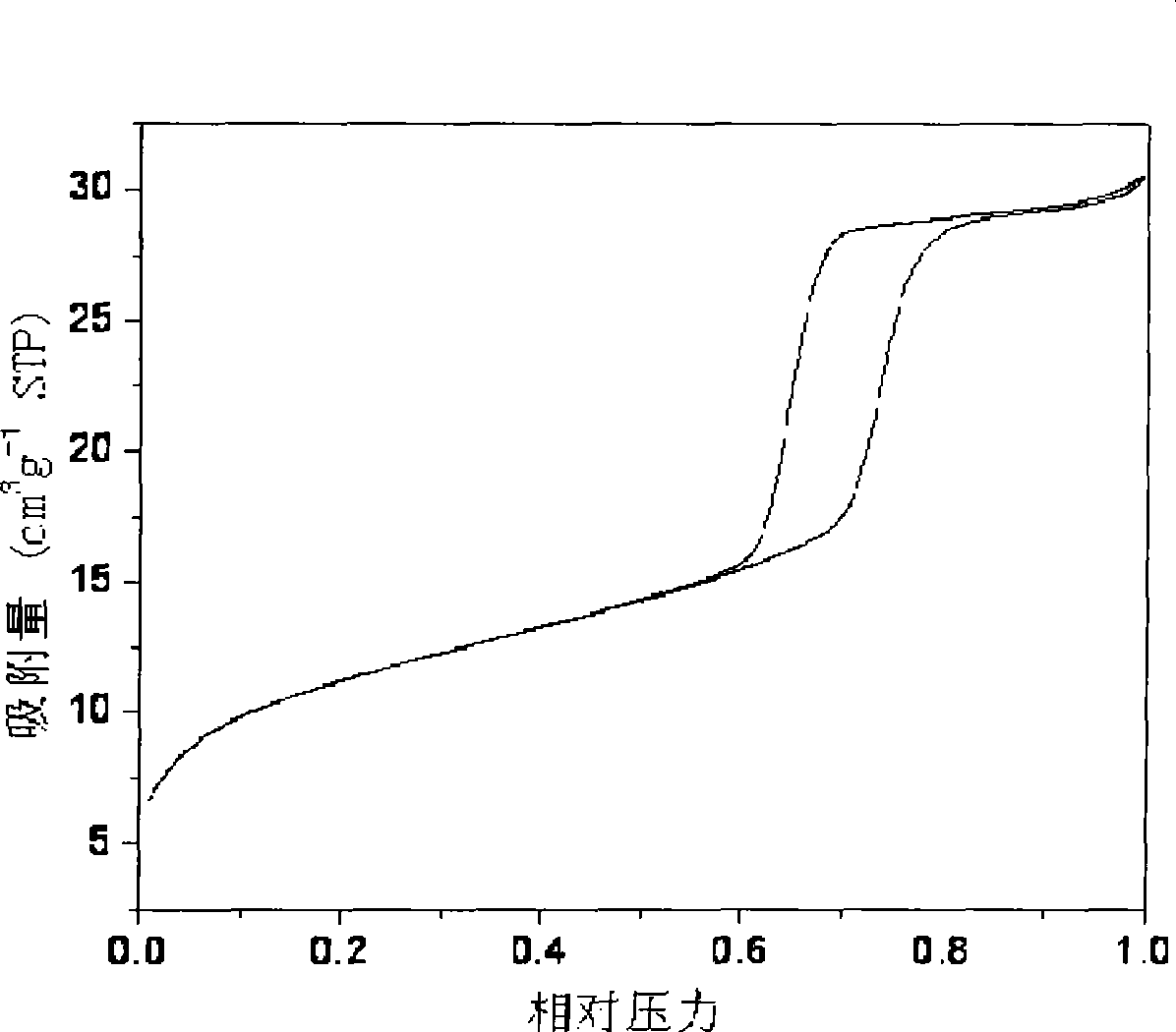

Embodiment 1

[0031] Dissolve 1.0 g of polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer (P123) (molecular weight 5800) in a certain amount of deionized water and stir until clear, stir for 1 hour, then add 2.08 g of tetraethyl orthosilicate ( TEOS) and 4ml of RE 3+ (where RE contains Y 3+ and Eu 3+ The molar ratio is n Y / n E=4.0) the total amount is 0.5mol / L rare earth nitrate solution, then add a certain amount of HCl solution so that its concentration in the final reaction medium is respectively 0.15, 0.30, 0.45 and 0.60mol / L, the final mixed solution The quantity ratio is: TEOS:RE:P123:H 2 O=1:0.2:0.017:210; the mixed solution continued to be stirred at 40°C for 24h, then transferred to a reactor with a plastic substrate and crystallized at 100°C for 48h, the obtained product was filtered, washed with deionized water, and Dry at room temperature, and then bake in static air at a rate of 1°C per minute to 500°C for 4 hours to remove the tri-block copolymer to obta...

Embodiment 2

[0033] 1.0g polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer (P123) and 0.10g dodecyltrimethylammonium bromide (C 12 TAB) was dissolved in a certain amount of deionized water and stirred until clear, stirred for 1h, then added 1.52g of methyl orthosilicate and 8.0, 4.0, 2.0, 1.0 and 0.5ml of RE 3+ (where RE contains Y 3+ and Eu 3+ The molar ratio is n Y / n Eu =4.0) the total amount is 0.5mol / L rare earth nitrate solution, then add a certain amount of HBr solution so that its concentration in the final reaction medium is respectively 0.45mol / L, and the amount ratio of substances in the final mixed solution is: orthosilicon Acid methyl ester:RE:P123:C 12 TAB:H 2 O=1: (0.40, 0.20, 0.10, 0.05, 0.025): 0.017:0.032:180; the mixed solution was stirred at 40°C for 24h, then transferred to a reactor with a plastic substrate and crystallized at 100°C for 48h. The obtained product was filtered, washed with deionized water, dried at room temperature, and then cal...

Embodiment 3

[0035] 0.51g cetyltrimethylammonium bromide (C 16 TAB) was dissolved in a certain amount of deionized water and stirred until clear, stirred for 1h, then added 1.22g of sodium silicate (Na 2 SiO 3 ) and 4.0ml of RE 3+ , the total amount is 0.5mol / L rare earth nitrate solution, where RE contains Y 3+ and Eu 3+ The molar ratio is n Y / n Eu =2.3, 3.0, 4.0, 5.7, 9.0, then add a certain amount of HNO 3 The concentration of the solution in the final reaction medium is 0.45mol / L respectively, and the ratio of substances in the final mixed solution is: Na 2 SiO 3 :RE:CTAB:H 2 O=1:(0.40, 0.20, 0.10, 0.05, 0.025):0.14:150; the mixed solution was stirred at 40°C for 24h, then transferred to a reactor with a plastic substrate and crystallized at 100°C for 48h, and the obtained The product was filtered, washed with deionized water, dried at room temperature, and then calcined in static air at a rate of 1 °C per minute to 500 °C for 4 h to remove the triblock copolymer to obtain r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com