Fiber chelated TiO2 visible light catalyst based on LMCT effect and N doping, and preparation method thereof

A catalyst and visible light technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as loss of visible light absorption, difficulty in obtaining visible light catalytic activity, etc., to achieve High visible photocatalytic activity, excellent long-term cycle stability, and convenient source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides a fiber chelated TiO based on LMCT effect and N doping 2 The preparation method of visible light catalyst, concrete steps are:

[0023] 1) Weigh butyl titanate, glacial acetic acid and absolute ethanol at a molar ratio of 1:2:5, mix them uniformly by magnetic stirring, and add them dropwise at a rate of 0.25mL / s to a volume ratio of 1:40 glacial acetic acid in deionized water. During this period, the obtained solution was continuously stirred vigorously, and after the mixed solution was dripped, the vigorous stirring was continued for 1-2h, and then it was allowed to stand and age for 12-84h under normal temperature and dark state conditions to obtain nano-TiO 2 crystal sol.

[0024] 2) place the amidoxime modified polyacrylonitrile fiber with a weight gain rate of 13-32% in the nano-TiO prepared in step 1 according to the weight ratio of 1:50 2 In the crystal sol, make it stir and react under airtight conditions at 90-100°C for 2-...

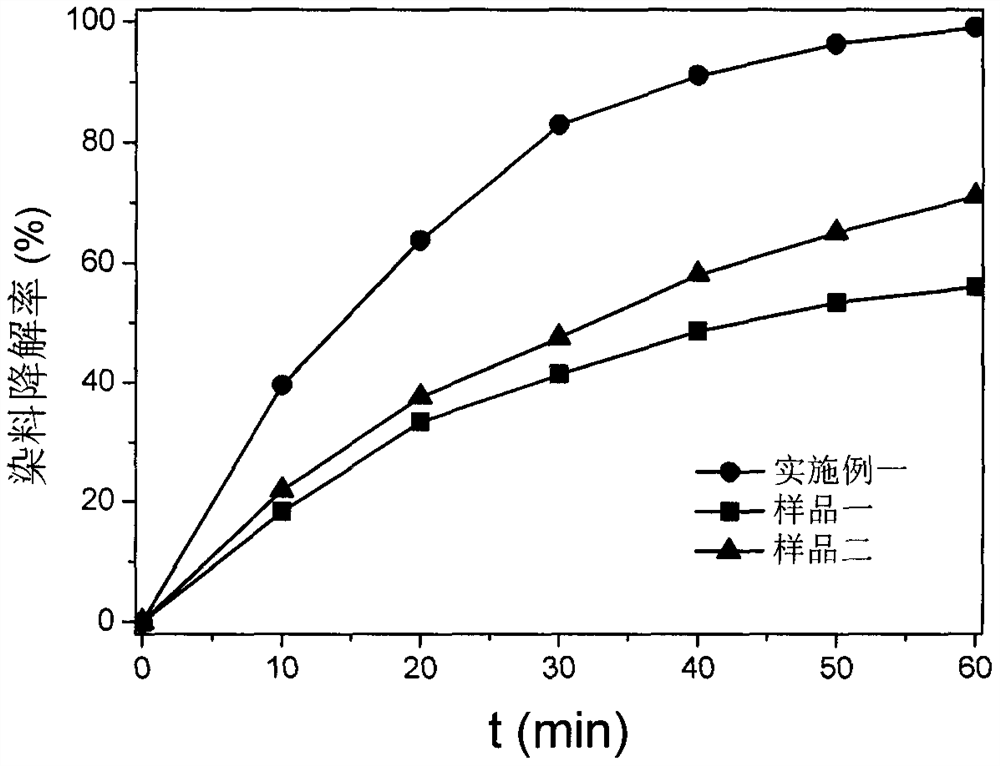

Embodiment 1

[0027] 1) Weigh butyl titanate, glacial acetic acid and absolute ethanol at a molar ratio of 1:2:5, mix them uniformly by magnetic stirring, and add them dropwise at a rate of 0.25mL / s to a volume ratio of 1:40 In deionized aqueous solution of glacial acetic acid, the TiO 2 The concentration is 0.12mol / L. During the period, the obtained solution was continuously stirred vigorously, and after the mixed solution was dripped, the vigorous stirring was continued for 2 hours, and then it was left to stand and aged for 36 hours at room temperature and in a dark state to obtain nano-TiO 2 crystal sol.

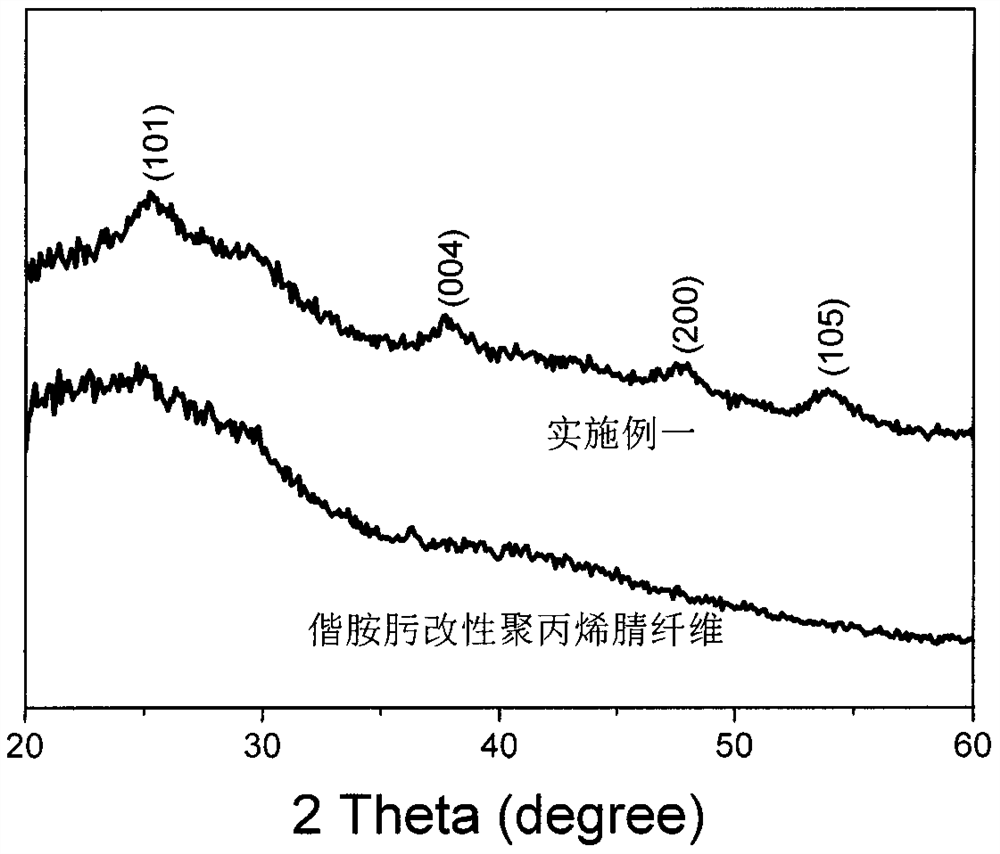

[0028] 2) Take by weighing the amidoxime modified polyacrylonitrile fiber of 1.0g weight gain rate 32%, it is placed in the nano-TiO that 50mL step 1 prepares 2 In the crystal sol, it was stirred and reacted for 3 hours under airtight conditions at 90°C, and then it was taken out and washed and dried repeatedly with distilled water to obtain the first fiber-chelated TiO based on LMC...

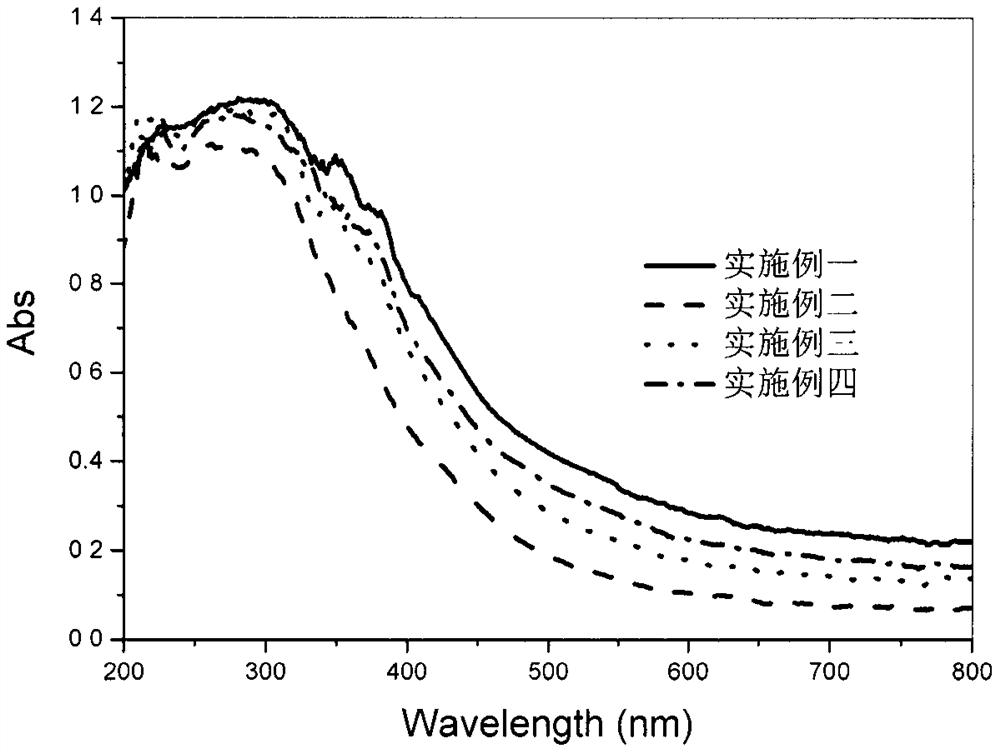

Embodiment 2 3 4

[0031] Adjust the amidoxime-modified polyacrylonitrile weight gain rate in Step 2 of Example 1 to 13%, 23% and 27% respectively, and the rest are the same as in Example 1 to obtain the second, third and fourth LMCT-based Effects and N-doped fiber chelation on TiO 2 visible light catalyst. Through measurement and calculation, the titanium content on the catalyst is 4.9mg / g, 5.7mg / g and 5.9mg / g respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com