Fluorine-doped TiO2/SBA-15 photocatalyst and application of fluorine-doped TiO2/SBA-15 photocatalyst in organic pollutant degradation

A photocatalyst and fluorine-doped technology, which is applied in the direction of physical/chemical process catalysts, water pollutants, molecular sieve catalysts, etc., can solve the problems that limit the application of TiO2, achieve high visible light catalytic activity, significant degradation efficiency, and improve adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

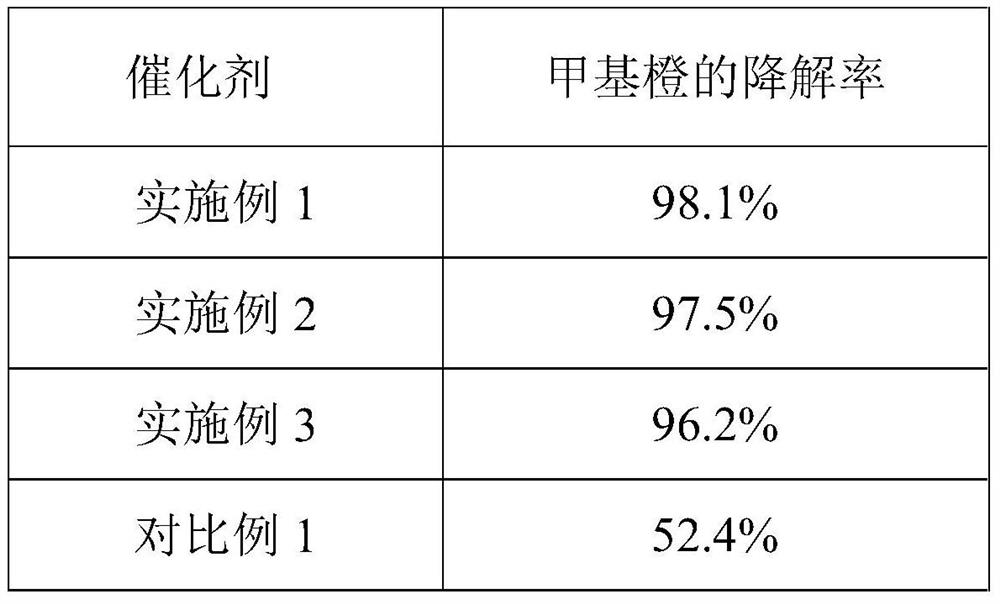

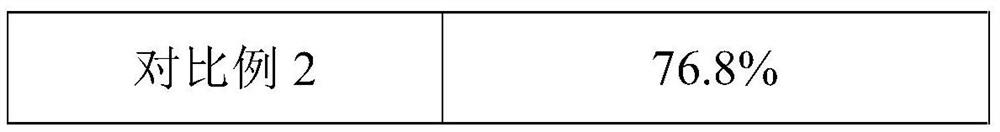

Embodiment 1

[0018] A fluorine-doped TiO 2 The photocatalyst of / SBA-15, its preparation method comprises:

[0019] S1. Add 1g of SBA-15 molecular sieve into 10mL ammonium fluoride aqueous solution (1mol / L), stir and mix for 0.5h, then hydrothermally react at 200°C for 8h, cool to room temperature, filter and wash with deionized water, Dry for 16 hours to obtain fluorine-modified SBA-15 molecular sieve;

[0020] S2. Add 4 mL of tetrabutyl titanate and 1 mL of glacial acetic acid into 20 mL of absolute ethanol and stir to obtain a tetrabutyl titanate ethanol solution; add 1 g of fluorine-modified SBA-15 molecular sieve to the above titanic acid under stirring conditions In tetrabutyl ethanol solution, after stirring for 0.5h, ultrasonically treat for 1h under the condition of frequency 45KHz; then add nitric acid solution (0.5mol / L) dropwise under stirring condition and stir for 0.5h, adjust the pH value to 2, continue Stirring for 1 hour, airtight aging for 24 hours, drying at 90°C for 1...

Embodiment 2

[0022] A fluorine-doped TiO 2 The photocatalyst of / SBA-15, its preparation method comprises:

[0023] S1. Add 1g of SBA-15 molecular sieve to 10mL of sodium fluoride aqueous solution (1mol / L), stir and mix for 0.5h, then hydrothermally react at 180°C for 10h, cool to room temperature, filter and wash with deionized water, Dry for 16 hours to obtain fluorine-modified SBA-15 molecular sieve;

[0024] S2. Add 5mL of tetrabutyl titanate and 1.5mL of glacial acetic acid into 20mL of absolute ethanol and stir to obtain a tetrabutyl titanate ethanol solution; add 1g of fluorine-modified SBA-15 molecular sieve to the above titanium After stirring for 0.5h, ultrasonic treatment was performed at a frequency of 45KHz for 1h; then nitric acid solution (0.5mol / L) was added dropwise under stirring and stirred for 0.5h to adjust the pH value to 2. Continue to stir for 1 hour, seal and age for 24 hours, dry at 80°C for 14 hours, and then calcinate at 450°C for 4 hours to obtain the fluorin...

Embodiment 3

[0026] A fluorine-doped TiO 2 The photocatalyst of / SBA-15, its preparation method comprises:

[0027] S1. Add 1g of SBA-15 molecular sieve to 10mL of hydrogen fluoride aqueous solution (1mol / L), stir and mix for 0.5h, then hydrothermally react at 200°C for 6h, cool to room temperature, filter and wash with deionized water, and dry at 120°C for 16h , to obtain fluorine-modified SBA-15 molecular sieve;

[0028] S2. Add 2 mL of tetrabutyl titanate and 0.5 mL of glacial acetic acid into 20 mL of absolute ethanol and stir to obtain a tetrabutyl titanate ethanol solution; add 1 g of fluorine-modified SBA-15 molecular sieve to the above titanium After stirring for 0.5h, ultrasonic treatment was performed at a frequency of 45KHz for 1h; then nitric acid solution (0.5mol / L) was added dropwise under stirring and stirred for 0.5h to adjust the pH value to 2. Continue to stir for 1 hour, seal and age for 24 hours, dry at 100°C for 10 hours, and then calcinate at 550°C for 2 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com