Production method for self-heat preserving energy-saving waterproof building block for architectural engineering

A technology of construction engineering and production methods, applied in the direction of cement production, chemical instruments and methods, manufacturing tools, etc., can solve the problems of ecological environment damage, easy cracking of walls, water consumption, etc., and achieve environmental protection, good heat insulation and insulation Acoustic performance, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The raw materials used in the self-insulation, energy-saving and waterproof block of the present invention are phosphogypsum, quicklime, dephosphorization and desulfurization catalyst, cement, hollow glass microspheres, methyl hydrogen-containing silicone oil waterproofing agent, mixed with water evenly, and formed by hydraulic ejection equipment. It is produced by non-calcined autoclave curing method.

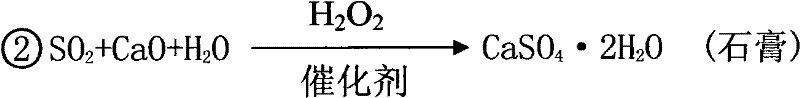

[0015] The technical key of the phosphogypsum self-heating, energy-saving and waterproof block of the invention is the phosphorus removal and desulfurization of the phosphogypsum. The invention adopts quicklime, water, phosphorus removal and desulfurization catalyst hydrogen peroxide to react rapidly under the catalysis, and produces calcium pyrophosphate and calcium sulfate which are harmless to building blocks and the environment, thereby achieving the purpose of phosphorus removal and desulfurization. It reacts as follows:

[0016]

[0017] The specific formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com