Collecting electrode IGBT having hole injection structure

A collector short-circuit and hole injection technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as increased conduction loss, increased on-resistance, and increased static loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

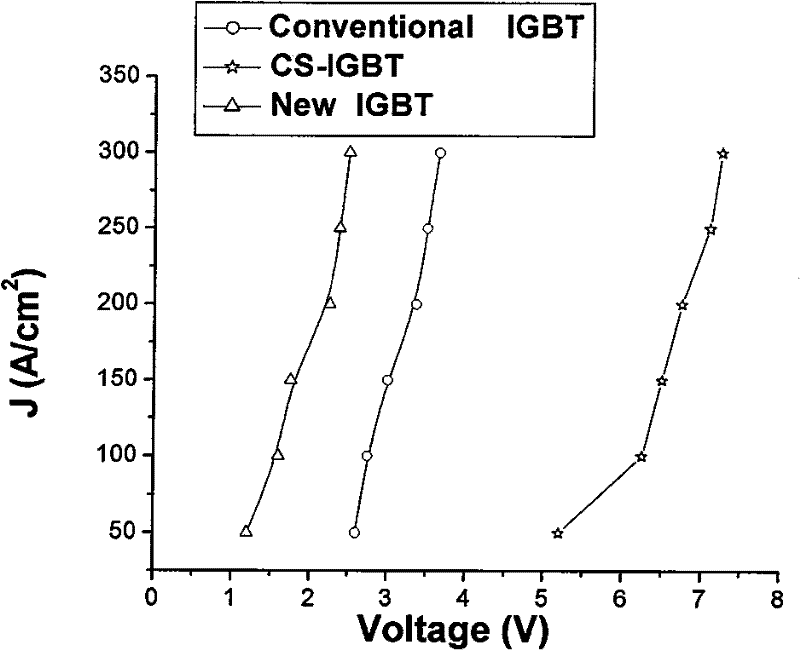

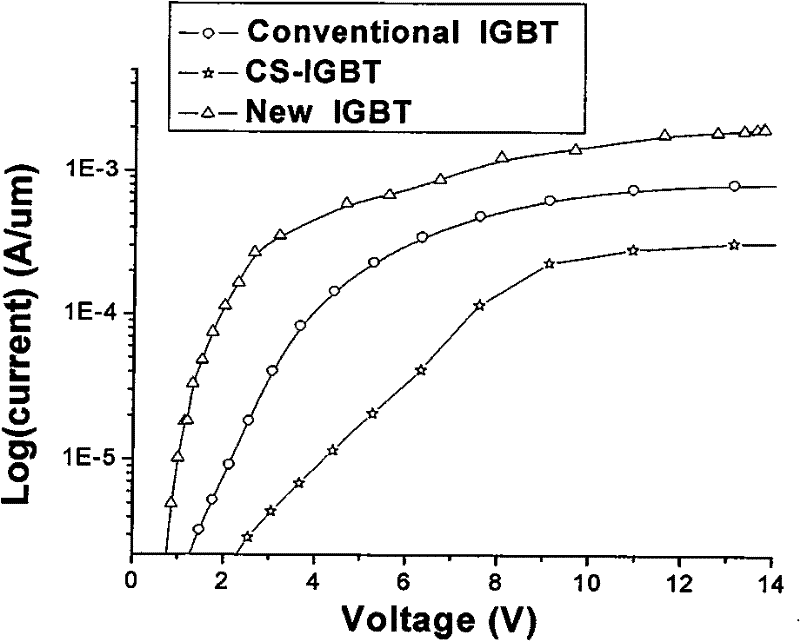

[0034] Adopting a collector short-circuit IGBT with a hole injection structure provided by the present invention can achieve low conduction voltage drop, high saturation current density, and better balance between forward conduction voltage drop and turn-off loss. compromise. With the development of semiconductor technology, more fast and low-power consumption devices can be produced by adopting the invention.

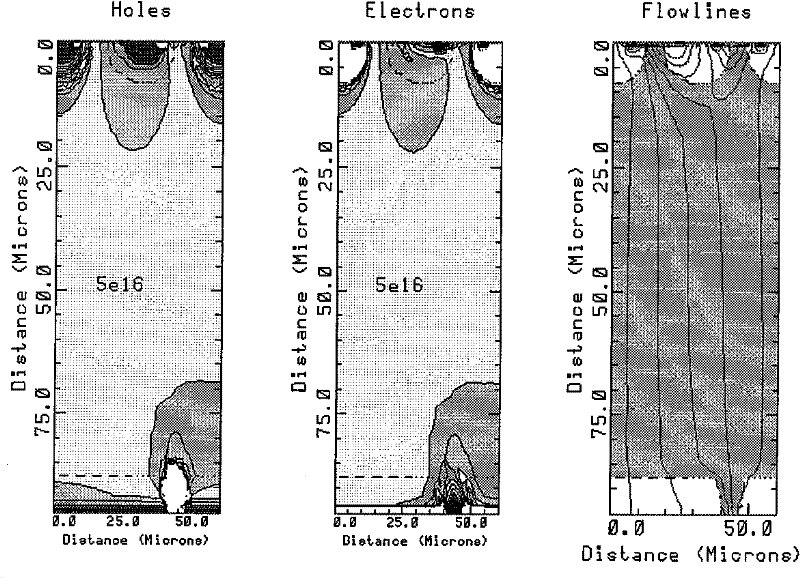

[0035] A short-collector IGBT with a hole-injection structure, such as Figure 4 As shown, it includes metallized collector 1, P-type collector 2, N - Base 4, P + Body region 5, P-type base region 6, N + Source region 7, polysilicon gate electrode 8, silicon dioxide gate oxide layer 9, metallized source electrode 10; the device is metallized collector electrode 1, P-type collector region 2, N - Base 4; Resident N - On both sides of the top of the base area 4, from bottom to top are the first P + Body region 5, first P-type base region 6, first N + source region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com