Process for producing wind power generator by casting technique

A technology of wind turbines and casting technology, which is applied to shafts, electrical components, electromechanical devices, etc., can solve the problems of insufficient feeding, coarse grains, low strength and toughness of castings, slow cooling speed, etc., so as to enhance market competitiveness. , Excellent mechanical properties, the effect of lowering the threshold requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

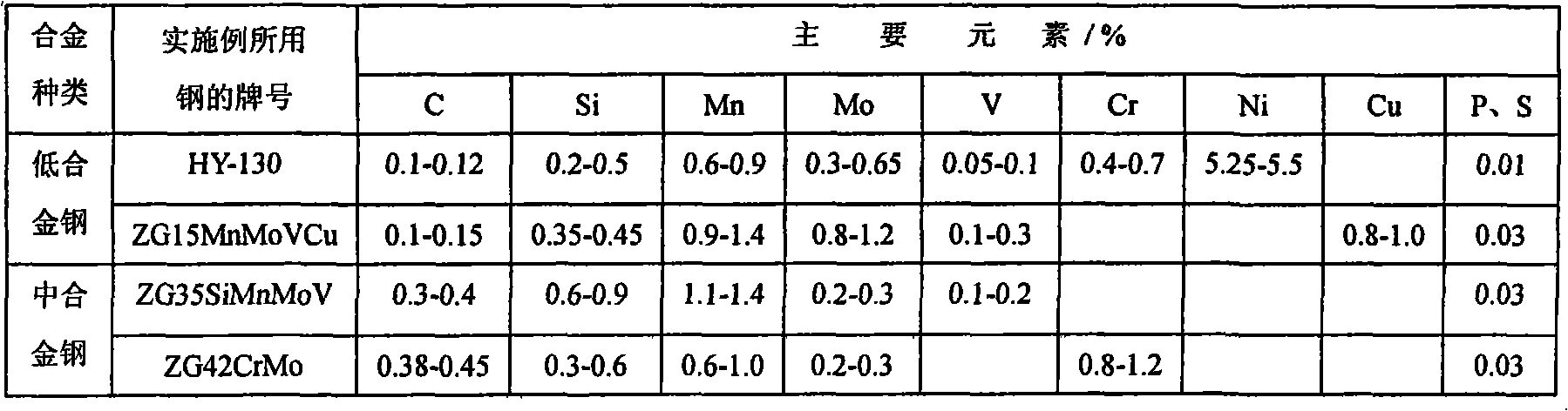

[0023] The materials used in the embodiment of the present invention are four low- and medium-alloy steels, the grades of which are HY-130, ZG15MnMoVCu, ZG35SiMnMoV, and ZG42CrMo, and their common chemical composition ranges are shown in Table 1, and Fe is the balance.

[0024] Table 1

[0025]

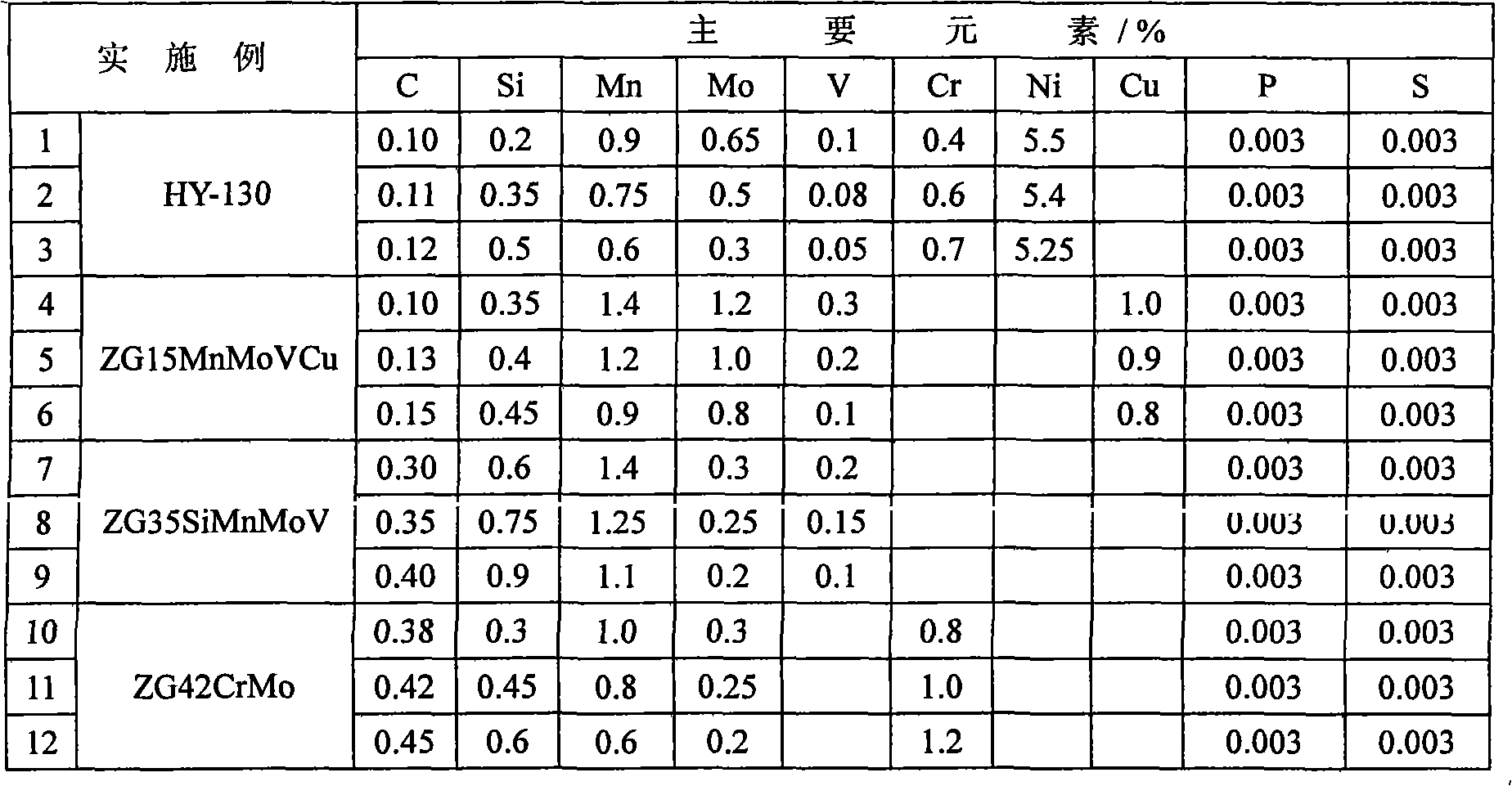

[0026] In the actual smelting process, the alloys of each brand were smelted with three components as examples. The specific components of each example are shown in Table 2, and Fe is the balance.

[0027] Table 2

[0028]

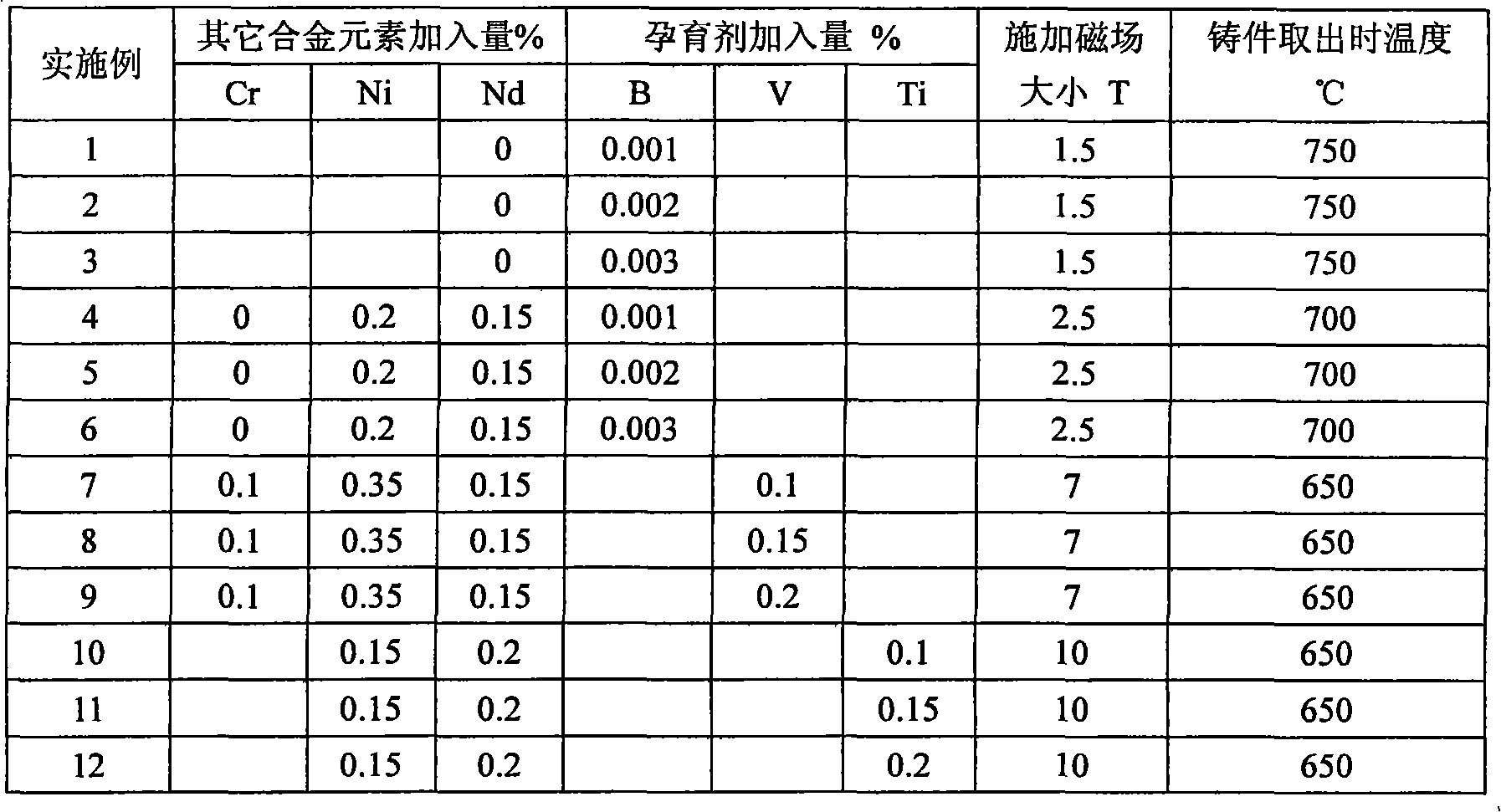

[0029]The alloys of each embodiment in Table 2 were smelted in a steelmaking furnace respectively. In order to minimize the content of P, S, O, H and other impurity elements in the alloy to improve toughness, Mn iron, Si iron and Al composite deoxidizers are used for sufficient deoxidation in the later stage of smelting, and the low alloy steel HY- Sprinkle B into 130 and ZG15MnMoVCu according to the measurement given in Table 3, sprinkle V into the medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com