Method for simultaneously acquiring protein and lipid from soybean

A soybean and protein technology, applied in the direction of edible oil/fat, protein food ingredients, protein composition of vegetable seeds, etc., can solve the problems of small quantity and strength, high processing cost, and unsatisfactory requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

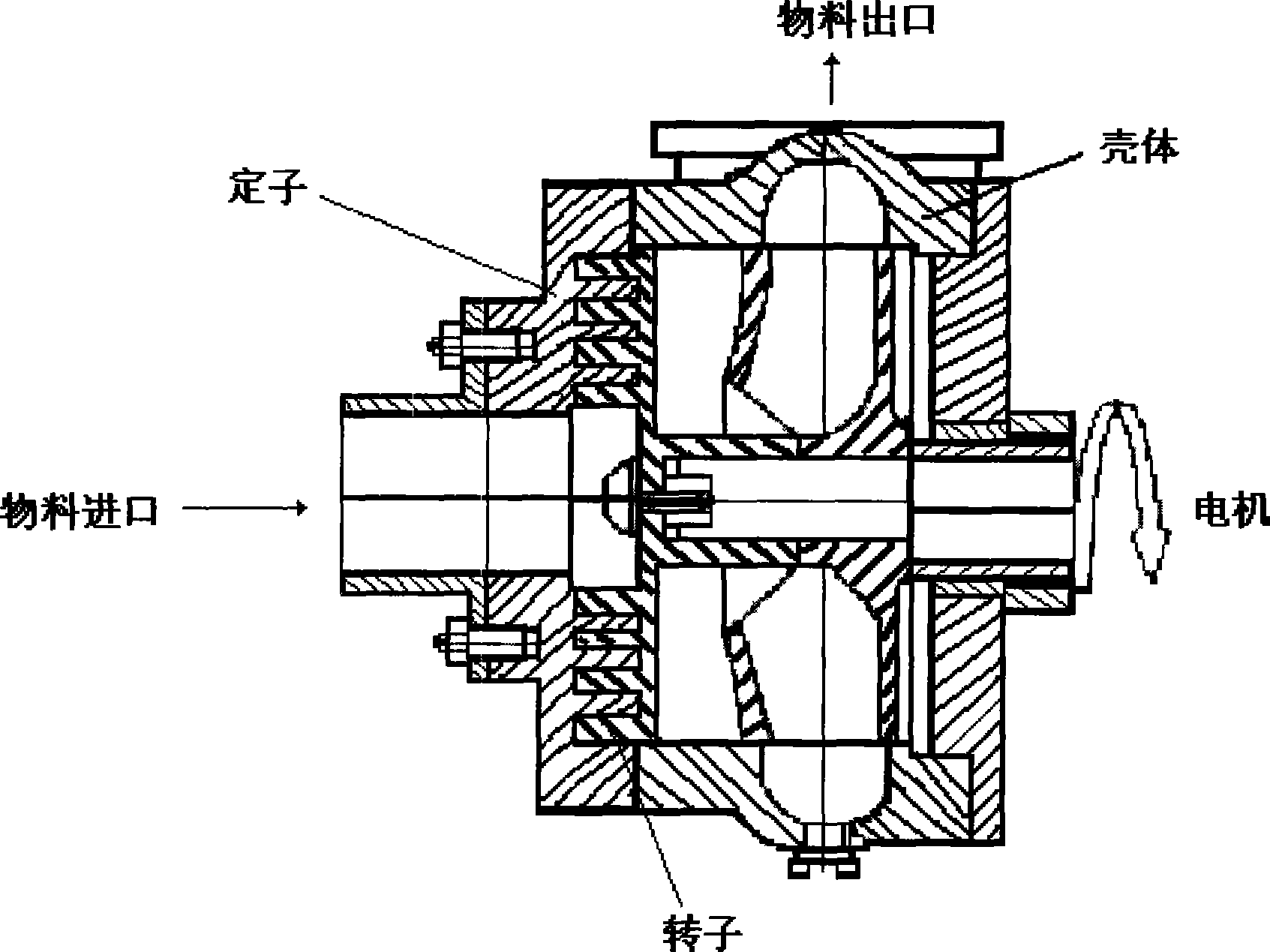

Image

Examples

example 1

[0010] Example 1: Take 100 kg of peeled soybean powder with an average particle size of 5 mm and 100 kg of mixed solvent, which is prepared by hexane and 90% aqueous ethanol in a weight ratio of 6:4. After preheating, it is pumped to a processing capacity of 10m 3 In the cavitation generator of / h, the preheating temperature and operating temperature are both 50°C, and the effluent from the machine is sampled and analyzed. Centrifuge to separate the solid and liquid phases first. After the solid phase is desolvated, the protein content is 72%. The liquid phase is divided into an oil-rich layer and an ethanol layer after cooling to 20°C. The oil-rich layer is taken to evaporate the hexane, and the obtained soybean oil is converted into weight. It is 96% of the total oil content of soybeans.

example 2

[0011] Example 2: Get 100 kilograms of peeled soybean powder with an average particle size of 2 mm and 120 kilograms of mixed solvent, which is prepared by hexane and 92% aqueous ethanol in a weight ratio of 6:4. After preheating, it is pumped to a processing capacity of 10m 3 In the cavitation generator of / h, the preheating temperature and the operating temperature are both 45°C, and the cycle is operated three times, and the effluent of the machine is sampled and analyzed. The solid and liquid phases were separated by centrifugation first. After the solid phase was desolvated, the protein content was 72.5%. The liquid phase was divided into an oil-rich layer and an ethanol layer after cooling down to 15°C. The oil-rich layer was evaporated to remove the hexane, and the obtained soybean oil was secondary soybean oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com