Process for advanced treatment of electroplating waste by integrated membrane

A technology of electroplating wastewater and advanced treatment, which is applied in general water supply saving, metallurgical wastewater treatment, osmosis/dialysis water/sewage treatment, etc. It can solve the problems of environmental secondary pollution and heavy metals that cannot be recycled and reused, and achieve zero discharge. Economical, the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

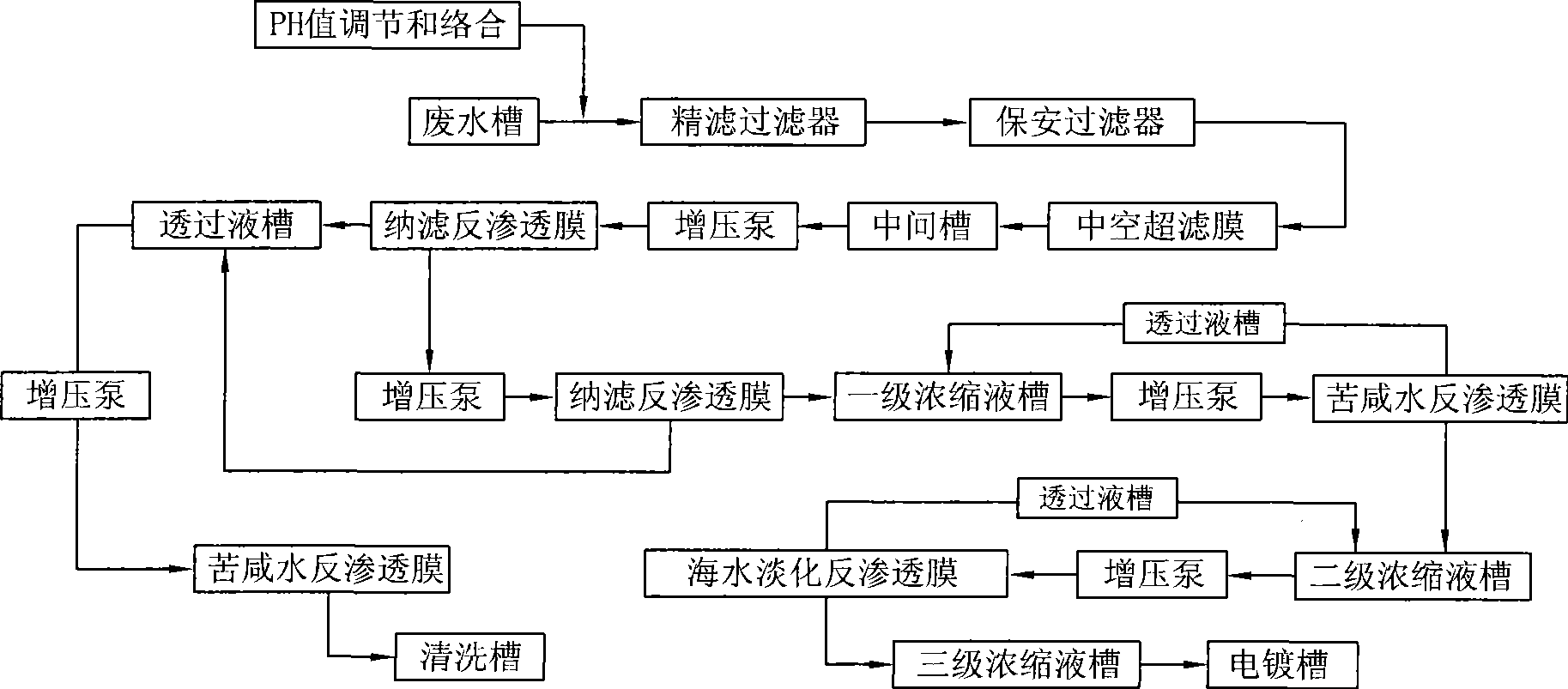

[0014] like figure 1 As shown, it is a flowchart of a process for advanced treatment of electroplating wastewater with integrated membranes in the present invention. The pH value of the electroplating wastewater in the wastewater tank is adjusted and complexed, so that the ions and organic matter that affect the quality of the product after reuse can be precipitated or After complexation, it is removed, and then it is preliminarily filtered through a fine filter and a security filter, and then enters a hollow ultrafiltration membrane to remove various organic coating agents and rust and other impurities in the electroplating wastewater, so as to protect various reverse osmosis in the subsequent process. The membrane is not blocked, so that the whole system can run smoothly.

[0015] The electroplating wastewater after the above pretreatment enters the middle tank, and the middle tank acts as a buffer. The electroplating wastewater in the middle tank is pressurized and then ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com