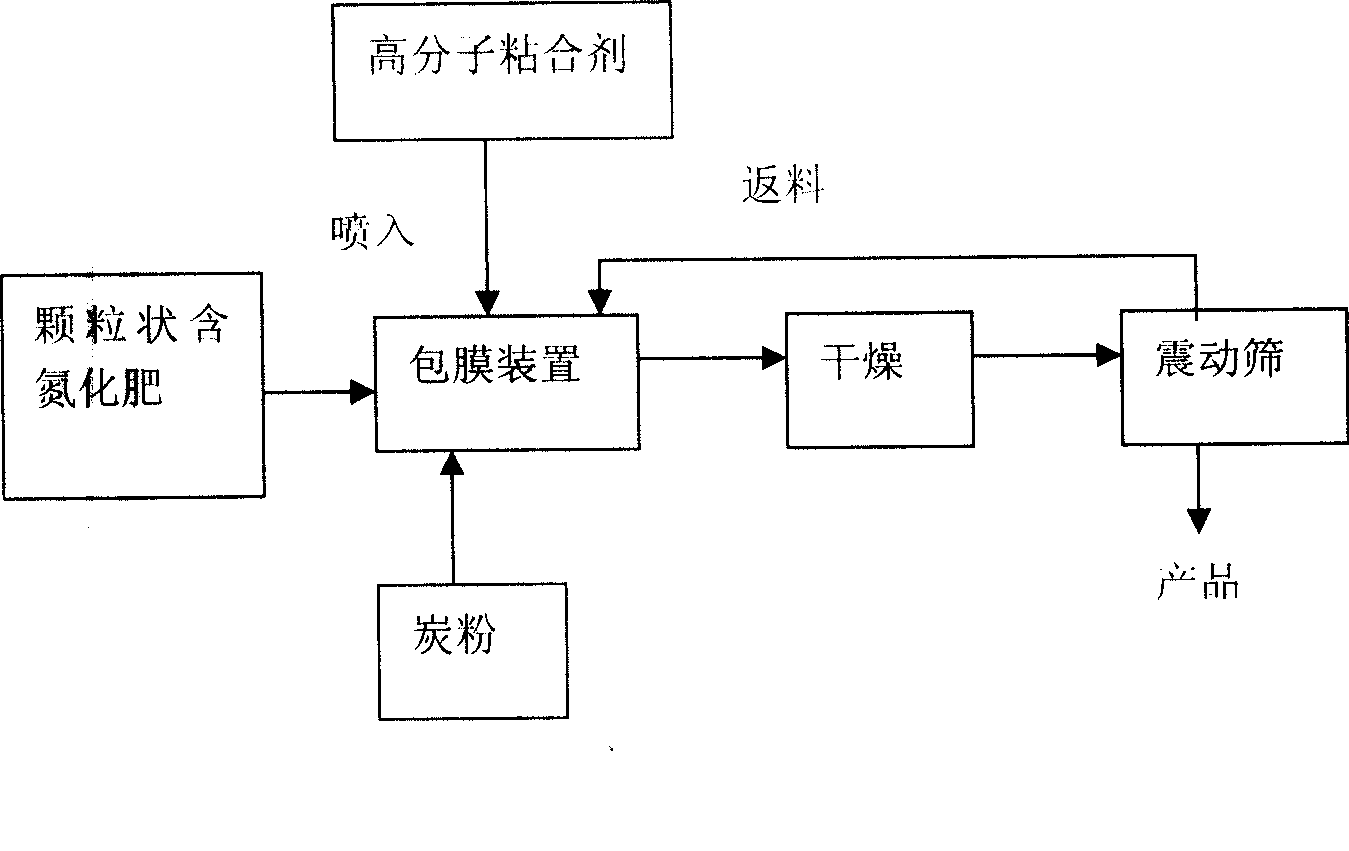

Production process of multiple-effect carbon nitrogen fertilizer

A technology of nitrogen fertilizer and charcoal, applied in the direction of nitrogen fertilizer, fertilizer form, ammonium salt fertilizer, etc., can solve the problems of high cost and limited large-scale application, and achieve the effect of low cost, low equipment requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take one kilogram of granular urea, place it in the coating pan of the coating machine, and adjust the rotation to about 400 rpm. 200 milliliters of 4% sodium carboxymethyl cellulose and ammonium humate mixed solution (each 50% of the ratio) are placed in the feed tank of the coating machine, and the spray gun is opened to spray the binder solution. Put hot air at 60-70℃ for about 3 minutes, then add a certain amount of charcoal into the rotating coating pan, continue to run for 2-3 minutes, then spray a certain amount of binder colloid solution, and then add charcoal, and so on 2-3 times; then transport the wrapped charcoal fertilizer to the composite vibrating dryer for drying, the temperature of the air inlet of the dryer is 70-90°C, the temperature of the material outlet is 40-60°C, after sieving, wait for more Effective carbon and nitrogen fertilizer granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com