VOC-free or VOC-poor polyurethane coating

A polyurethane polymer, weight technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as unstable coatings, insufficient mechanical properties, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

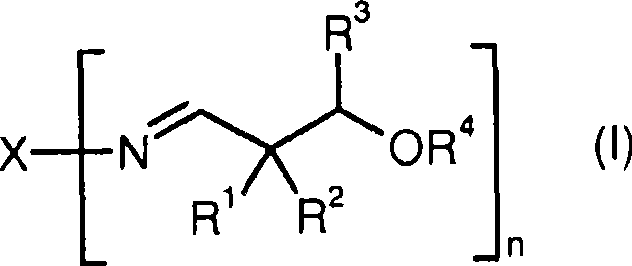

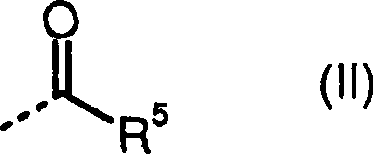

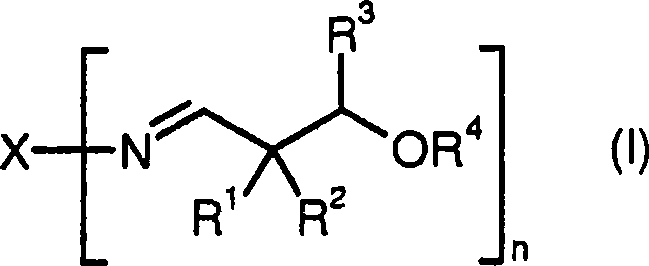

Method used

Image

Examples

Embodiment 1

[0173] 30 parts by weight of XP 2599 (viscosity 3.7Pa·s at 20°C) and 1.5 parts by weight of N 3600 mixed with each other. The viscosity of the mixture was 3.6 Pa·s at 20°C.

[0174] Then 12 parts by weight of polyaldimine ALD1 are mixed in uniformly. The viscosity of the mixture was 1.26 Pa·s at 20°C.

Embodiment 2

[0176] 24.85 parts by weight of polyurethane polymer P1 and 8 parts by weight of Z4470 mixed with each other. The viscosity of the mixture was 7.5 Pa·s at 20°C.

[0177] Then 12 parts by weight of polyaldimine ALD1 are mixed in uniformly. The viscosity of the mixture was 1.66 Pa·s at 20°C.

[0178] Examples 1 and 2 show the good diluting effect of the polyaldimines of the formula (I) in mixtures each comprising a polyurethane polymer P and an oligomeric polyisocyanate OP.

[0179] d) Preparation of filled compositions, application as a coating

Embodiment 3

[0181]The composition of Example 3 is suitable as a one-component, odorless curing, VOC-free and yellowing-resistant coating, for example as a resilient floor covering in the interior area.

[0182] In a vacuum mixer, mix 300 g of XP 2599, 15g N 3600, 5g of p-toluene-sulfonyl isocyanate, 500.4g of dry barium oxide (natural barium sulfate), 4g of Foamex N (Tego Chemie), 1.6g of benzoic acid, 4g of A 555 (Byk Chemie), 40g of titanium dioxide, 10g of 292 (Ciba) and 120 g of polyaldimine ALD1 were processed to a homogeneous, flowable mass, which was stored with exclusion of moisture.

[0183] The composition has a viscosity of 3 Pa·s at 20°C.

[0184] The composition was cast with a layer thickness of 1.1 mm onto a flat PTFE substrate and kept at 23° C. and 50% relative air humidity. 24 hours after application forms a tack-free elastic coating which cures after 7 days at 23° C. and 50% relative air humidity with

[0185] Shore A-hardness is 80,

[0186] The tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com