Method and apparatus for producing nanofiber and polymeric web

A technology of nanofibers and polymer nets, applied in fiber processing, nanotechnology, textiles and papermaking, etc., can solve problems such as difficult maintenance, and achieve the effects of easy maintenance, simple manufacturing, and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

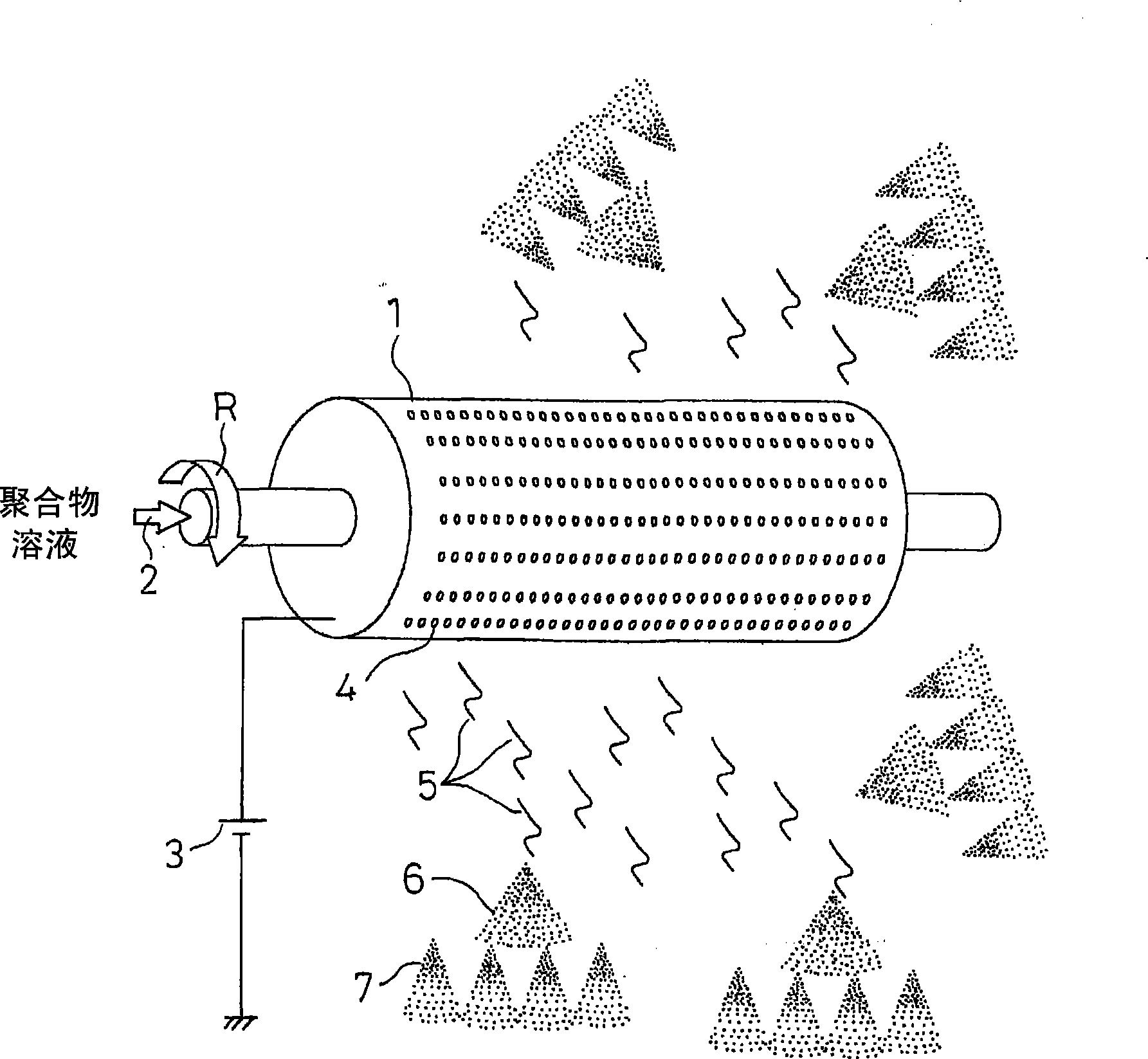

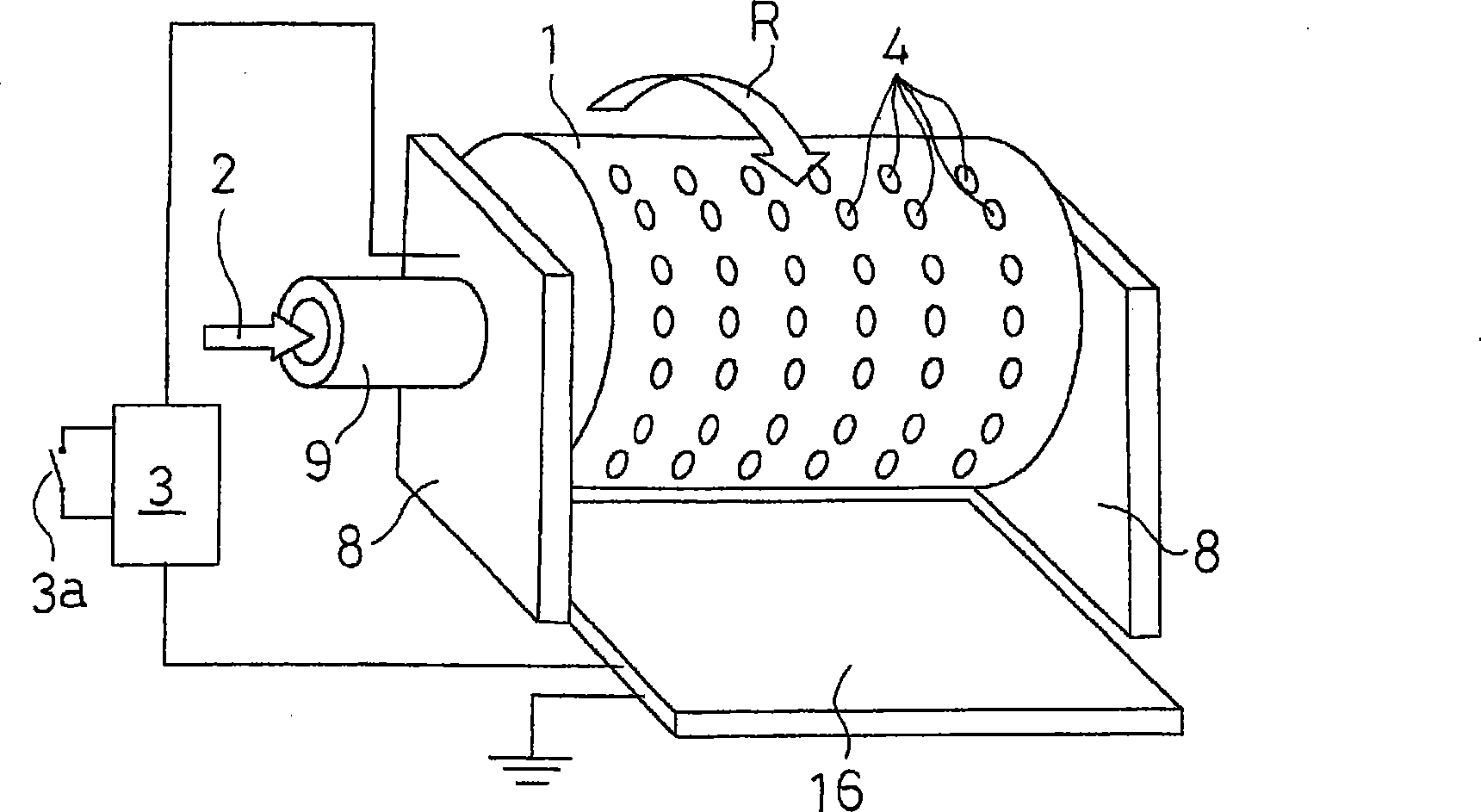

[0057] will be combined with Figure 1-7B Embodiment 1 of a method and apparatus for producing a polymeric network is described. figure 1 is a schematic diagram illustrating the principle of a method of producing nanofibers, which is applied to the method of producing a polymer network of the present embodiment. exist figure 1 Among them, reference numeral 1 denotes a cylindrical container, which is a rotating container with a diameter of 20-500 mm. The rotating container is driven to rotate around the axis of rotation as indicated by arrow R at a rotational speed of 30-6000 rpm. A polymer solution 2 is supplied to a rotating container 1 from one end thereof. In this case, the polymer solution is prepared by dissolving a polymer as a raw material of the nanofibers in a solvent.

[0058] Examples of the polymer forming the polymer solution 2 include polypropylene, polyethylene, polystyrene, polyethylene oxide, polyethylene terephthalate, polybutylene terephthalate, polyet...

Embodiment approach 2

[0072] Next, combine the Figure 8 Embodiment 2 of the method and apparatus for producing a polymer network of the present invention is described. In the description of the following embodiments, the same components appearing in the above embodiments are denoted by the same reference numerals, descriptions of these components are omitted, and only differences are described.

[0073] In the above-mentioned embodiment, an example is described in which the central shaft 9 is fixed on the support member 8 and the cylindrical container 1 is rotatably supported by the bearing 10 around the central shaft 9 . However, in this embodiment, if Figure 8 As shown, the cylindrical container 1 is fixed on the central shaft 9, and the two ends of the central shaft 9 are rotatably supported by the supporting element 8, and the supporting element 8 has a bearing 10 arranged between the supporting element 8 and the central shaft 9. Therefore, the rotary drive 15 is arranged such that the outp...

Embodiment approach 3

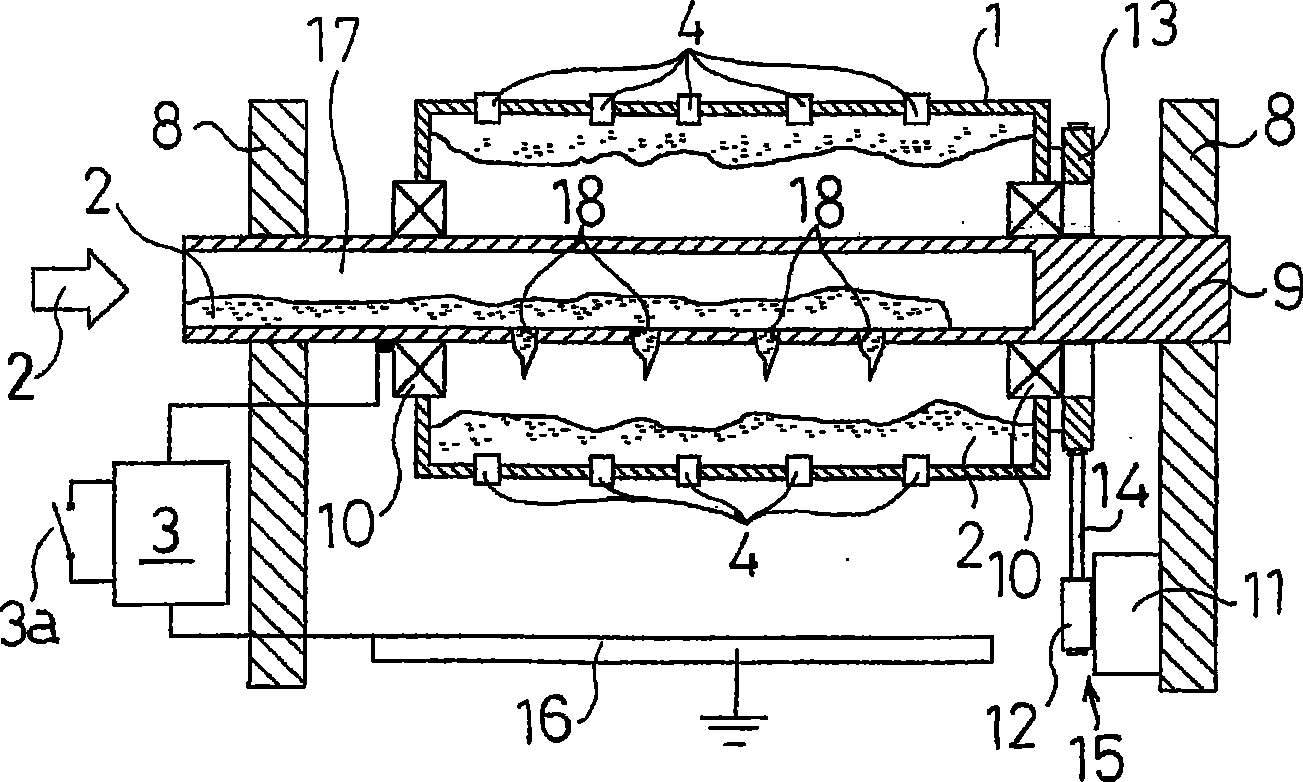

[0076] Next, combine the Figure 9 Embodiment 3 of the method and apparatus for producing a polymer network of the present invention is described.

[0077] In the above-mentioned embodiment, an example is described in which the high voltage generated by the high voltage generating device 3 with respect to the ground potential is applied to the cylindrical container 1, and the collector 16 is kept at the ground potential. However, in this embodiment, the positive or negative high voltage generated by the high voltage generator 3 is applied to the collector 16 , and the cylindrical container 1 is grounded through the conductive element 29 and the bearing 10 .

[0078] In this embodiment, the polymer filaments 5 are expelled from a cylindrical container 1 held at a high positive or negative voltage relative to the collector 16 . Then, the polymer solution forming these polymer filaments 5 is charged under the action of the electric field generated between the cylindrical contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com