Preparation and use of maize yellow powder protein hydrolysate with hypotensive function

A protein hydrolyzate and corn yellow powder technology, applied in the field of plant protein development and utilization, can solve the problems of long process, high production cost, slow hydrolysis rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

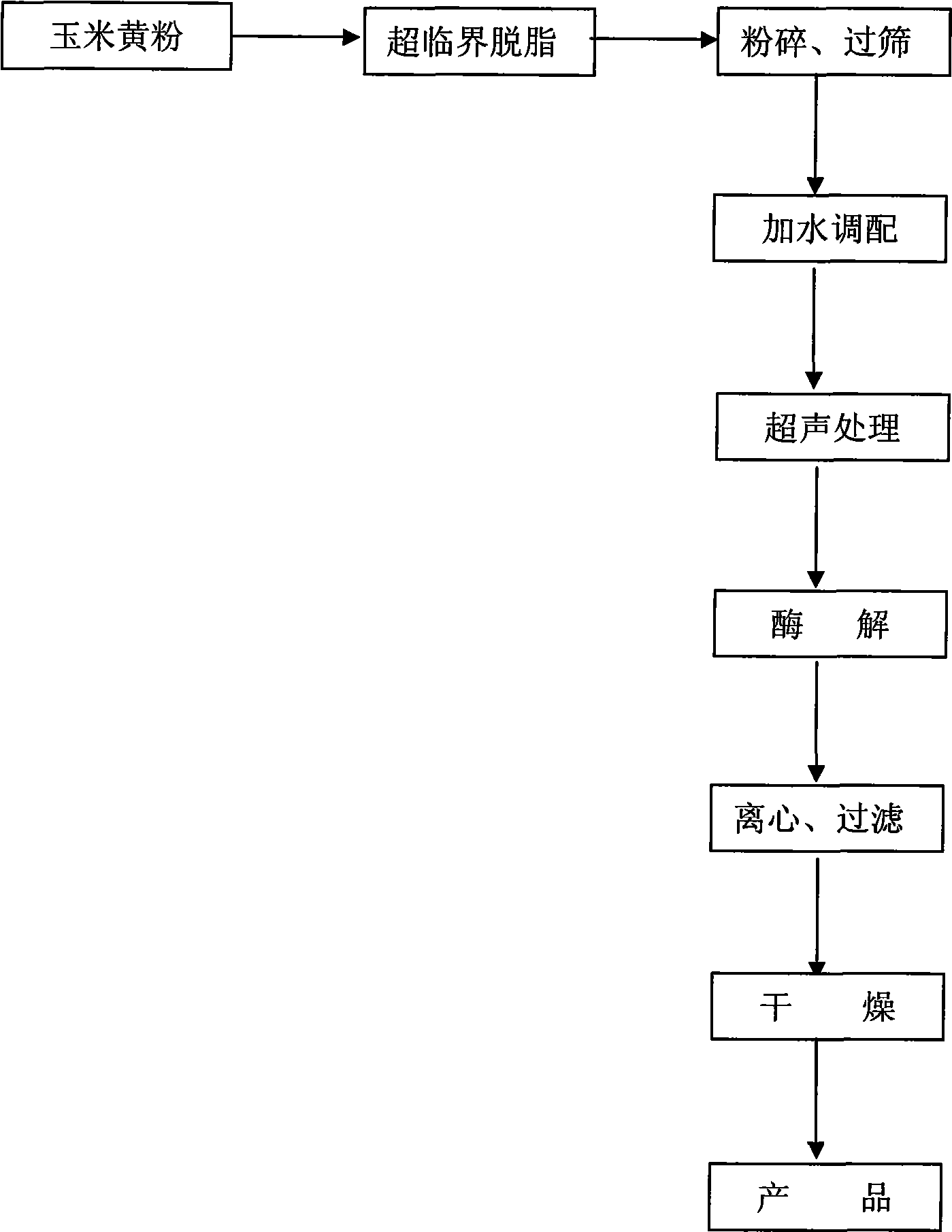

Method used

Image

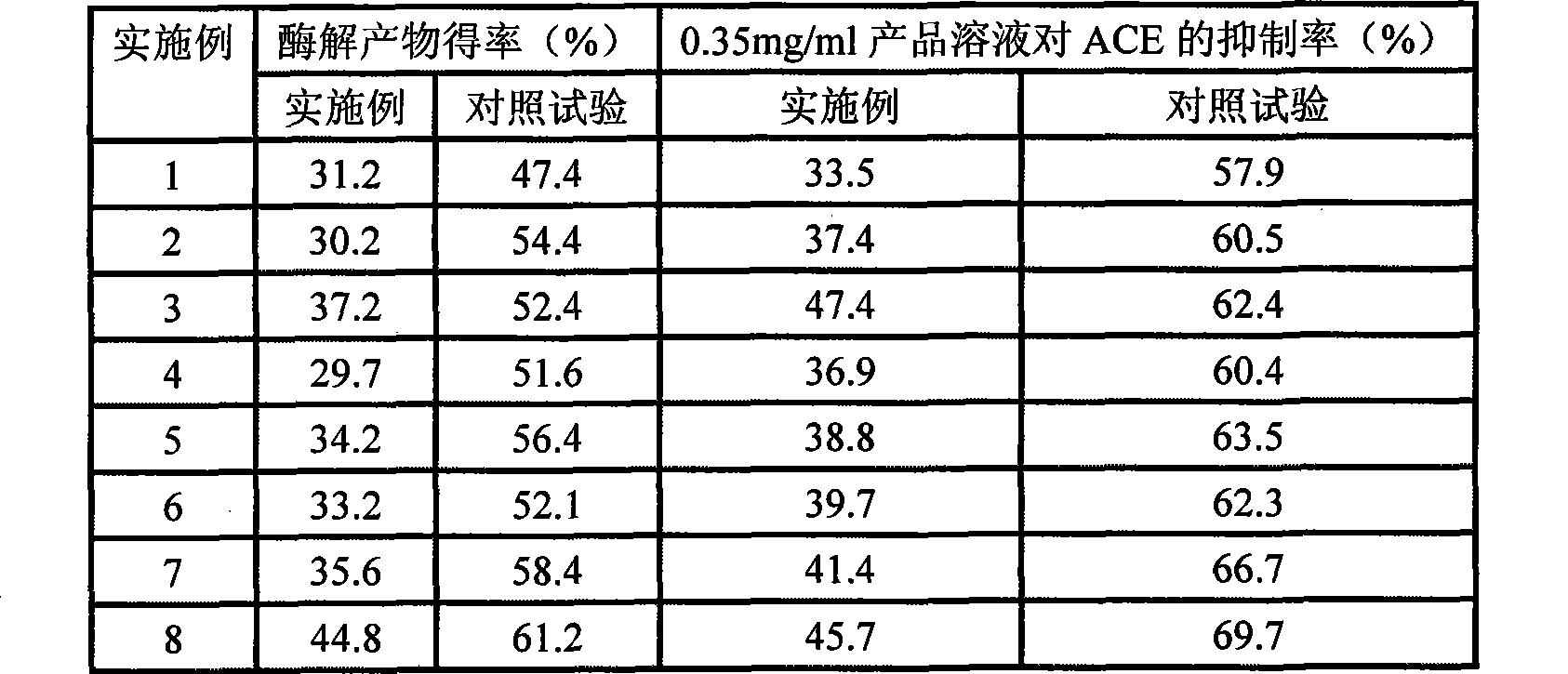

Examples

Embodiment 1

[0012] Feedstock utilizes supercritical CO 2 Oil removal, extraction pressure 30MPa, extraction temperature 35°C, separation pressure 5MPa, separation temperature 40°C, extraction time 3h. The degreased raw materials are pulverized until they all pass through a 40-mesh sieve. Weigh 50kg of the above-mentioned raw materials, add 250kg of water to prepare and carry out ultrasonic treatment, respectively put 4 concentrated ultrasonic heads with ultrasonic frequency of 20kHz on the circumference of the extraction tank, ultrasonic power 500W, ultrasonic work / intermittent time 1S / 1S, the initial temperature of the feed liquid is 20°C, and the ultrasonic time is 80min. During the process of ultrasonic treatment, the material liquid is continuously stirred to ensure uniform ultrasonic treatment. Add 0.25kg of neutral protease after ultrasonic treatment (protease activity meets the requirements of qualified products in QB / T 1805.3-93), temperature 55°C, pH 6.0, keep temperature and ...

Embodiment 2

[0023] Feedstock utilizes supercritical CO 2 Oil removal, extraction pressure 30MPa, extraction temperature 35°C, separation pressure 5MPa, separation temperature 40°C, extraction time 3h. The degreased raw materials are pulverized until they all pass through a 40-mesh sieve. Weigh 51.2kg of the above raw materials and 700kg of water to prepare and carry out ultrasonic treatment, respectively put 4 concentrated ultrasonic heads with ultrasonic frequency of 20kHz on the circumference of the extraction tank, ultrasonic power 1000W, ultrasonic work / intermittent time 3S / 3S, the initial temperature of the feed liquid is 25°C, and the ultrasonic time is 40min. During the process of ultrasonic treatment, the material liquid is continuously stirred to ensure uniform ultrasonic treatment. Add 0.15 kg of neutral protease after the ultrasonic treatment (protease activity meets the requirements of qualified products in QB / T 1805.3-93), temperature is 55°C, pH is 6.0, and the temperatur...

Embodiment 3

[0027] Feedstock utilizes supercritical CO 2Oil removal, extraction pressure 30MPa, extraction temperature 35°C, separation pressure 5MPa, separation temperature 40°C, extraction time 3h. The degreased raw materials are pulverized until they all pass through a 40-mesh sieve. Weigh 50kg of the above raw materials, 1000kg of water, and then carry out ultrasonic treatment, respectively put 4 concentrated ultrasonic heads with ultrasonic frequency of 20kHz on the circumference of the extraction tank, ultrasonic power 2000W, ultrasonic work / intermittent time 10S / 10S , the initial temperature of the feed liquid is 45°C, and the ultrasonic time is 20min. During the process of ultrasonic treatment, the material liquid is continuously stirred to ensure uniform ultrasonic treatment. Add 0.05kg of neutral protease after ultrasonic treatment (protease activity meets the requirements of qualified products in QB / T 1805.3-93), temperature 55°C, pH 6.0, keep temperature and pH constant duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com