Test probe apparatus

A test probe and test pin technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of leaving pits on the printed circuit board, affecting the quality of the printed circuit board, etc., to eliminate contact resistance, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

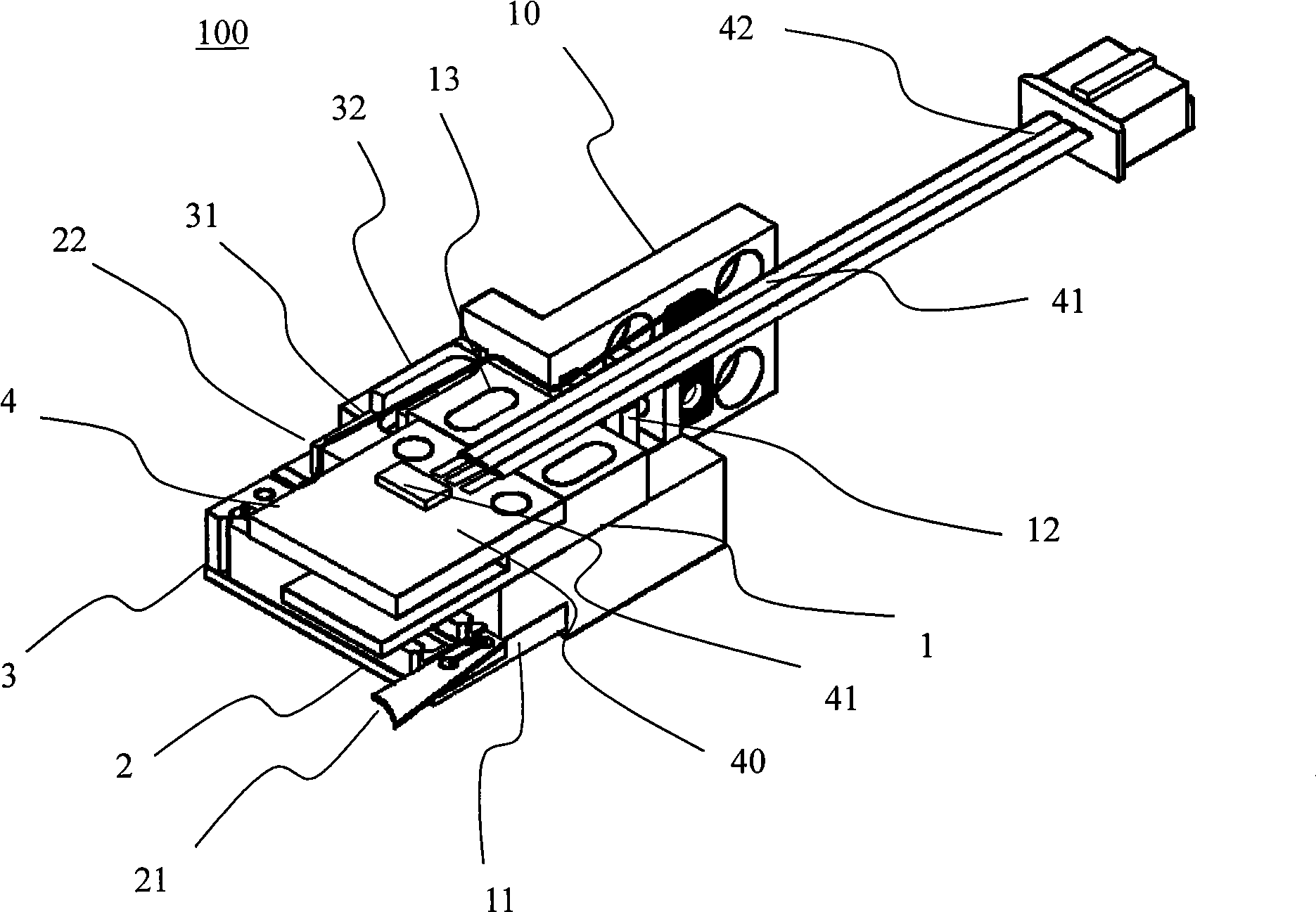

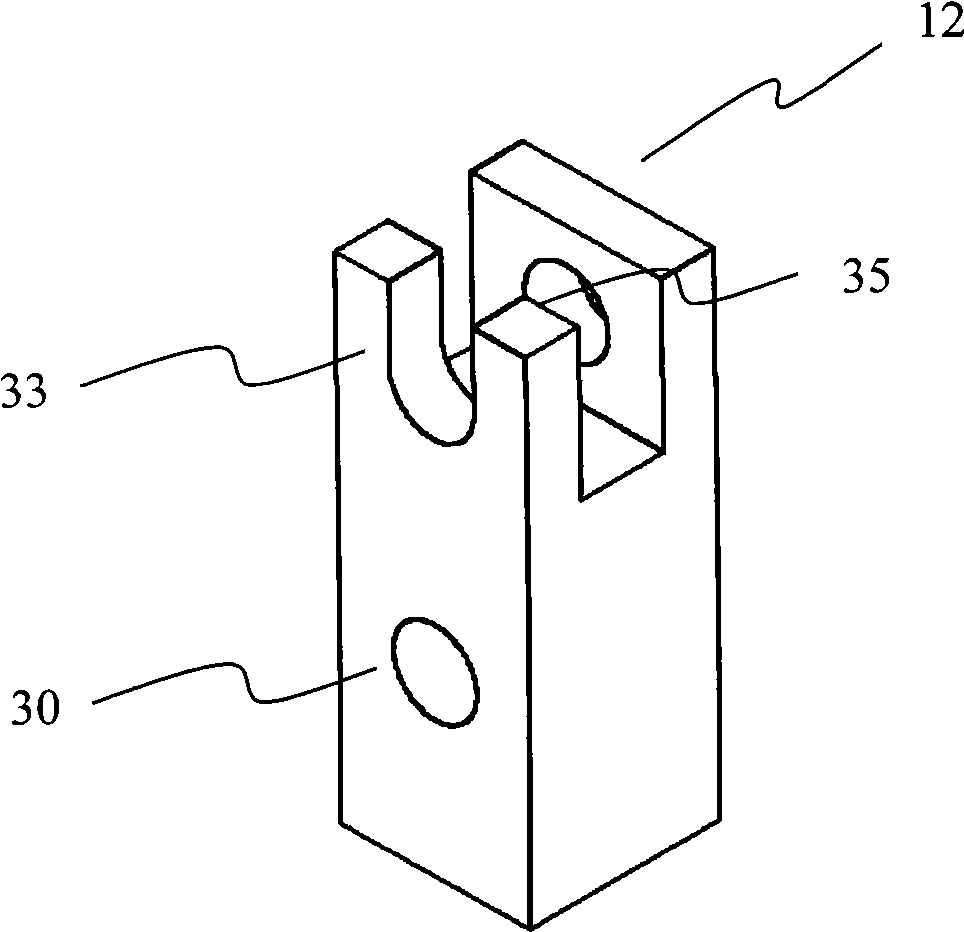

[0025] Such as figure 1 As shown, a test probe device 100 is composed of a needle holder main body 1, a test needle 20, a plastic spring bracket 3 and a pressure sensor 4, wherein the needle holder main body is composed of a fixing seat 10, a test needle fixing seat 11, and a U-shaped pressure adjustment The test needle 2 includes a knife-shaped test probe 21 and a signal output line 22 connected to the test probe. The signal output line 22 is connected to the fixing seat 10 at the rear end of the main body; the test needle 2 is fixed on the On the plastic spring support 3, the plastic spring support 3 is fixed on the front end of the needle seat main body 1 through the test needle holder 11; the pressure sensor 4 includes a pressure sensor main body 40, a pressure data transmission line 41 and a pressure data transmission line connector 42, the pressure sensor main body 40 is fixed on the upper surface of the needle holder main body 1 through the pressure sensor fixing part 1...

Embodiment 2

[0031] The difference between this embodiment and the previous example is:

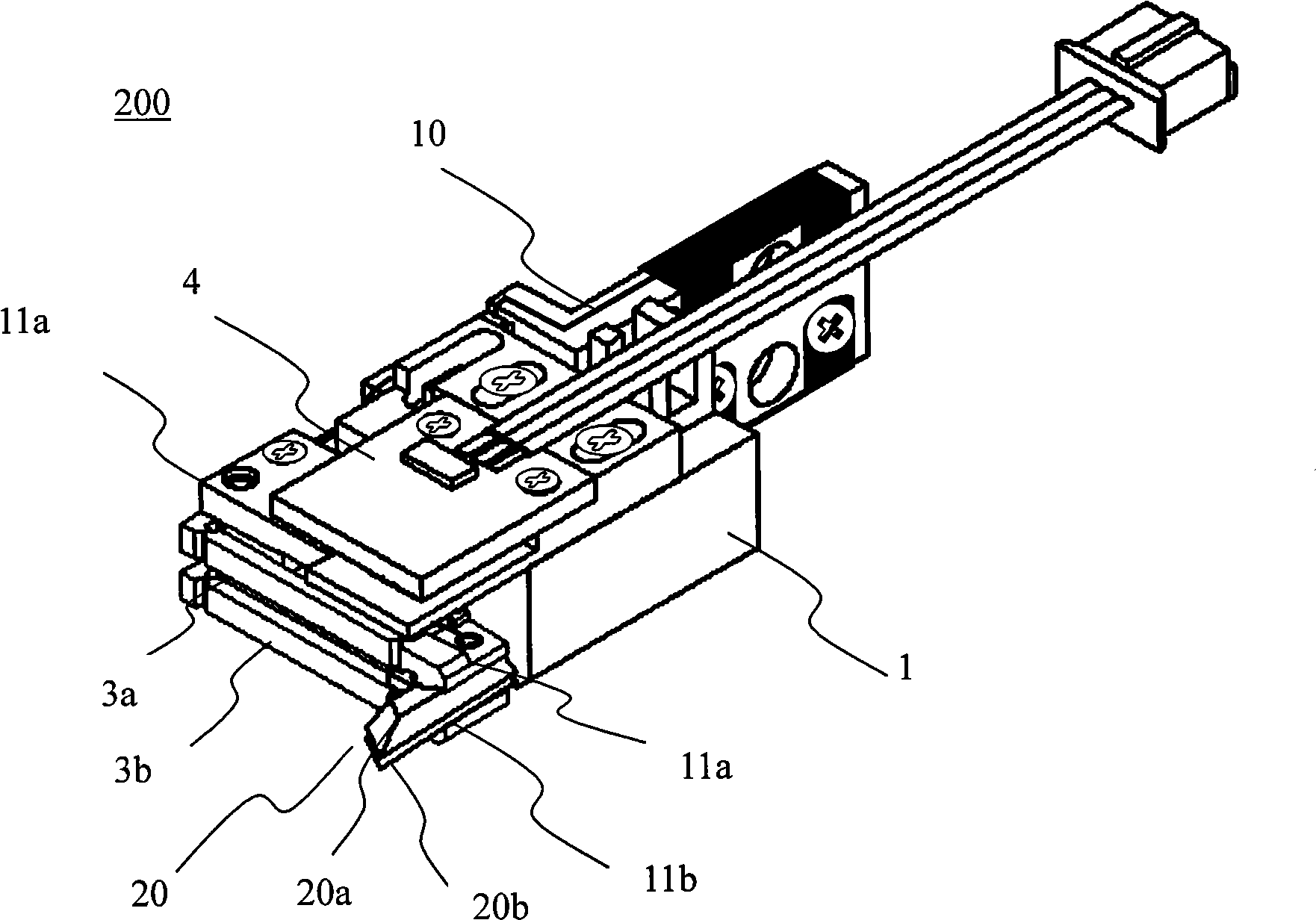

[0032] Such as figure 2 As shown, the test pin 20 includes two parallel upper and lower test pins 20a, 20b, the upper and lower test pins 20a, 20b are knife-type test probe test pins, and the opposite surfaces of the two knife-type test probes 2a, 2b are connected to each other. insulation. The plastic spring support 3a of the upper test needle is fixed on the fixing seat 10 at the front end of the needle holder, and the upper test needle holder 11a combines the plastic spring support 3b of the lower test needle with the plastic spring support 3a of the upper test needle. The signal output lines 22 on the two knife-type test probes 2a, 2b are respectively led to the rear end sampling points of the needle sockets for current and voltage sampling respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com