Modified active coke, production and uses thereof

A technology of active coke and modification, which is applied in the field of modified active coke and its preparation, can solve the problems of high cost, achieve the effect of high cost, great economic value and social significance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, the preparation of modified active coke

[0029] 1. Preparation of Modifier

[0030] A potassium bromide (KBr) aqueous solution with a mass percent content of 0.1% was prepared.

[0031] 2. Preparation of active coke

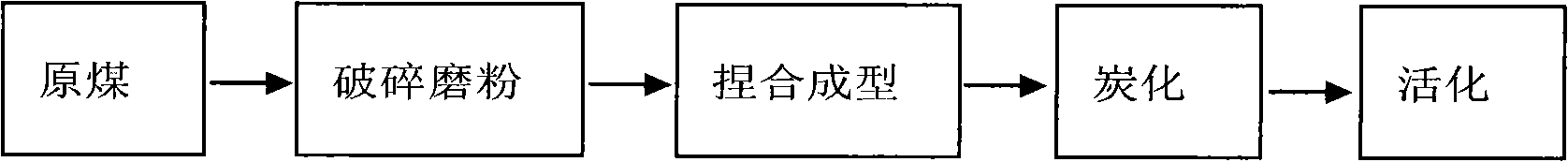

[0032] Process route such as figure 1 As shown, the details are as follows:

[0033] 1. Crush the anthracite, then grind and knead it, form it into strips, and dry it for later use.

[0034] 2. Carbonize the product of step 1 at a final temperature of 550° C. for 2 hours to obtain a carbonized product.

[0035] 3. Activate the carbonization product in step 2 at a temperature of 800° C. for 1 hour to obtain activated coke.

[0036] 3. Preparation of modified activated coke

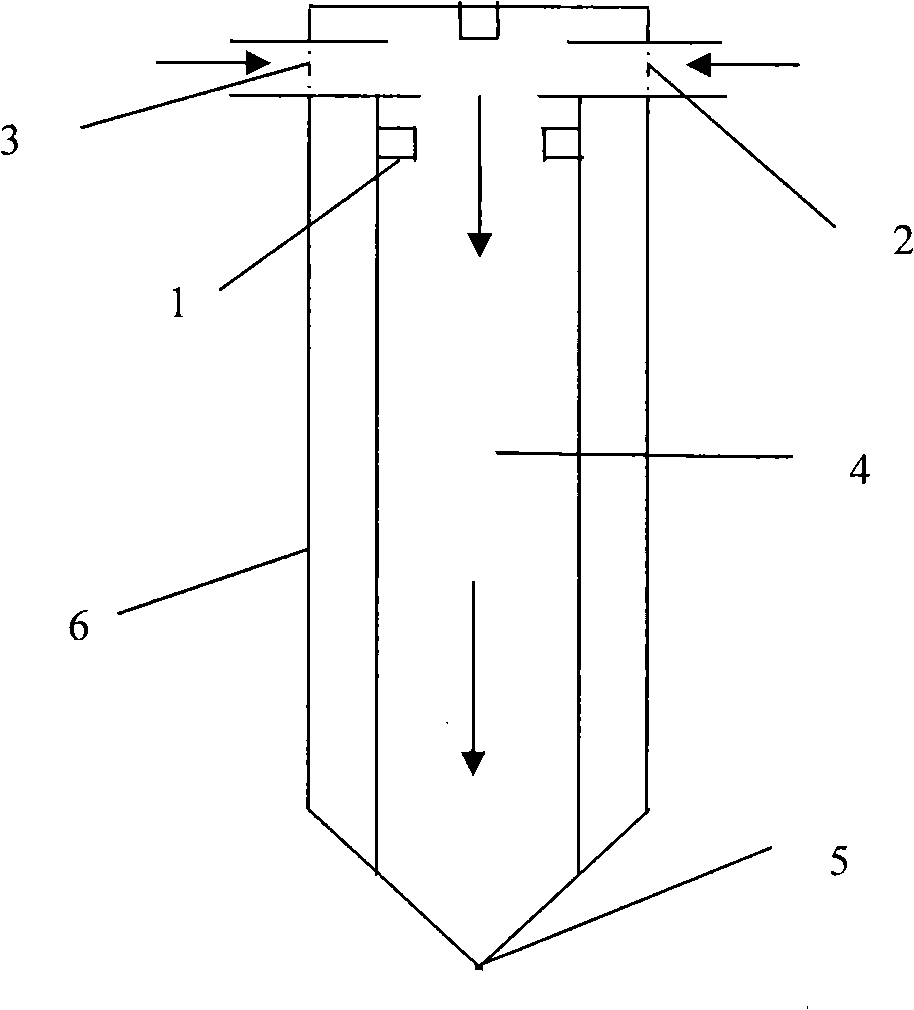

[0037] Modified active coke was prepared by coating method. use figure 2 The shown device prepares modified active coke. figure 2 The shown device is a closed system from top to bottom, including spray nozzle (1), right inlet (2), left inlet (3), heating zone (...

Embodiment 2

[0039] Embodiment 2, the preparation of modified active coke

[0040] 1. Preparation of Modifier

[0041] Preparation mass percentage composition is 10% potassium bromate (KBrO 3 ) aqueous solution.

[0042] 2. Preparation of active coke

[0043] Process route such as figure 1 As shown, the details are as follows:

[0044] 1. Crush the anthracite, then grind and knead it, form it into strips, and dry it for later use.

[0045] 2. Carbonize the product of step 1 at a final temperature of 700° C. for 1 hour to obtain a carbonized product.

[0046] 3. Activate the carbonized product in step 2 at a temperature of 950° C. for 0.5 hour to obtain activated coke.

[0047] 3. Preparation of modified activated coke

[0048] Modified active coke was prepared by coating method. use figure 2 The shown device prepares modified active coke. When in use, it is heated in the heating zone (from the middle section to the lower section of the furnace body), and the heating temperature ...

Embodiment 3

[0050] Embodiment 3, the preparation of modified active coke

[0051] 1. Preparation of Modifier

[0052] A potassium iodide (KI) aqueous solution with a mass percentage content of 1% was prepared.

[0053] 2. Preparation of active coke

[0054] Process route such as figure 1 As shown, the details are as follows:

[0055] 1. Crush the anthracite, then grind and knead it, form it into strips, and dry it for later use.

[0056] 2. Carbonize the product of step 1 at a final temperature of 700°C for 0.5 hours to obtain a carbonized product.

[0057]3. Activate the carbonized product in step 2 at a temperature of 850° C. for 1.5 hours to obtain activated coke.

[0058] 3. Preparation of modified activated coke

[0059] Modified active coke was prepared by coating method. use figure 2 The shown device prepares modified active coke. When in use, it is heated in the heating zone (from the middle section to the lower section of the furnace body), and the heating temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com