Method for photoelectrocatalysis oxidization of organic waste water with ozone

A technology of ozone catalytic oxidation and photoelectric catalysis, applied in chemical instruments and methods, oxidized water/sewage treatment, electrochemical water/sewage treatment, etc., can solve the problems of low efficiency and high cost, achieve economical value and reduce treatment costs , the effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

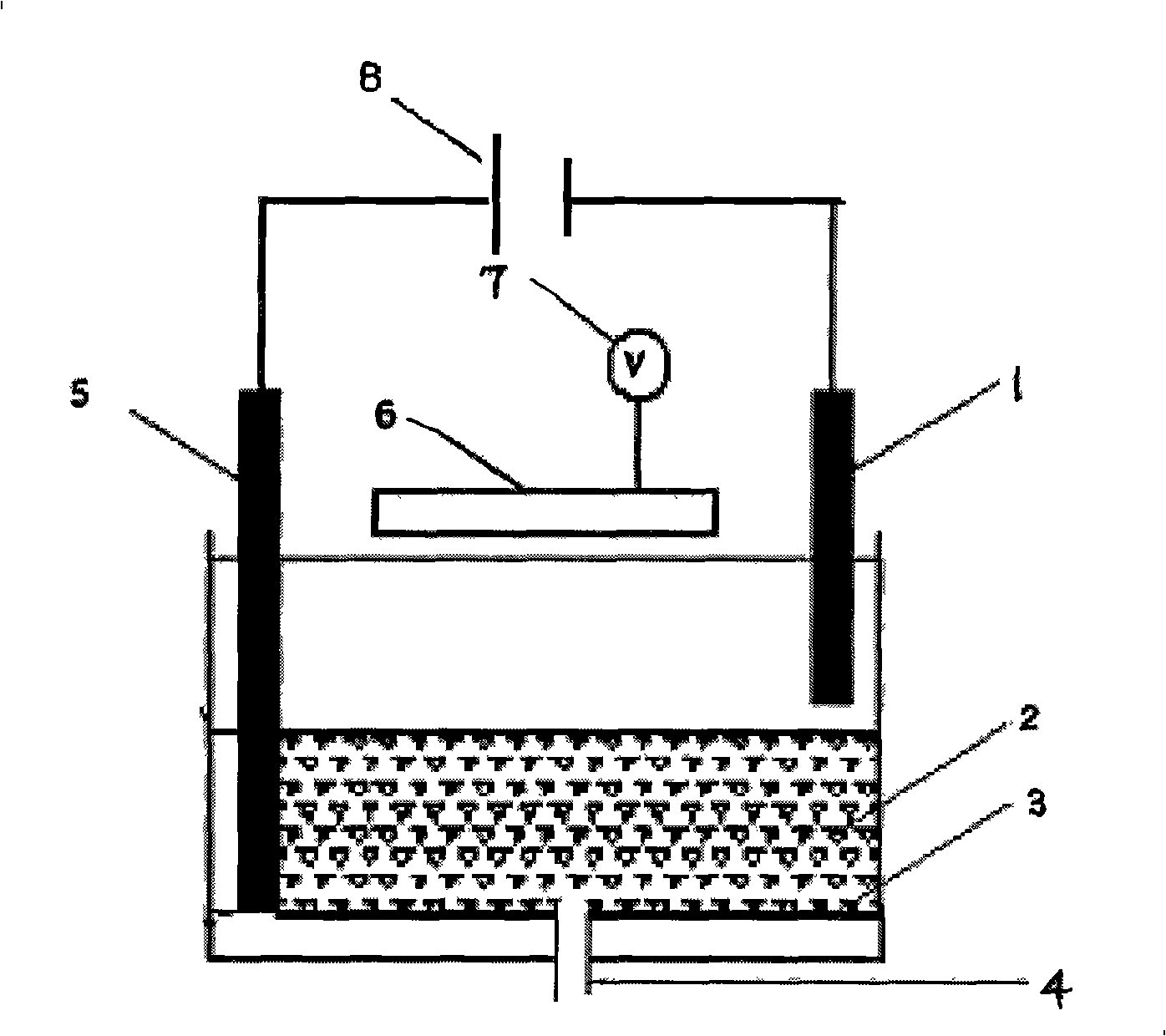

[0020] like figure 1 As indicated, add 500 mL of 10 mg / L neutral red solution into the reactor. A UV lamp with a power of 4W was placed on top of the reactor. 25g of activated carbon-supported titanium dioxide catalyst is placed at the bottom of the reactor as the anode, and the carbon rod is used as the cathode, and the applied cell pressure is 2V. Ozone enters the reactor through the bottom aeration device, the dosage is 15mg / min, the reaction time is 60min, and the ozone tail gas is absorbed through the KI absorption bottle.

[0021] The neutral red solution treated by single ozone catalytic oxidation and photoelectric catalytic oxidation has a removal rate of 43% and 66% respectively, and the neutral red solution treated under the above conditions has a removal rate of 85% after measurement, which has Better degradation effect.

Embodiment 2

[0023] like figure 1 As indicated, add 500 mL of 10 mg / L neutral red solution into the reactor. A UV lamp with a power of 9W was placed on top of the reactor. 25g of activated carbon-supported titanium dioxide catalyst is placed at the bottom of the reactor as the anode, and the carbon rod is used as the cathode, and the applied cell pressure is 2V. Ozone enters the reactor through the bottom aeration device, the dosage is 15mg / min, the reaction time is 60min, and the ozone tail gas is absorbed through the KI absorption bottle.

[0024] The neutral red solution treated by single ozone catalytic oxidation and photoelectric catalytic oxidation has a removal rate of 43% and 76% respectively, and the neutral red solution treated under the above conditions has a removal rate of 95% after measurement, which has Better degradation effect.

Embodiment 3

[0026] like figure 1 As shown, 500 mL of printing and dyeing wastewater with an initial COD of about 700 mg / L was added to the reactor. A UV lamp with a power of 9W was placed on top of the reactor. 25g of activated carbon-supported titanium dioxide catalyst is placed at the bottom of the reactor as the anode, and the carbon rod is used as the cathode, and the applied cell pressure is 2V. Ozone enters the reactor through the bottom aeration device, the dosage is 50mg / min, and the reaction time is 60min. The ozone tail gas is absorbed through the KI absorption bottle.

[0027] Single ozone catalytic oxidation and photoelectric catalytic oxidation treatment of printing and dyeing wastewater, the measured COD removal rate is 75% and 33%, respectively, and the printing and dyeing wastewater solution treated under the above conditions, the measured COD removal rate is 92%, has a relatively high Good degradation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com