Process for producing permanent ferrite with high-fracture toughness property

A permanent magnet ferrite and fracture toughness technology, which is applied in the direction of magnetism of inorganic materials, can solve the problems of shortening the free path of crack propagation, increasing the safety hazard of magneto, and reducing the fracture toughness of materials, so as to achieve sufficient solid-phase reaction and improve magnetic properties. and mechanical properties, the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

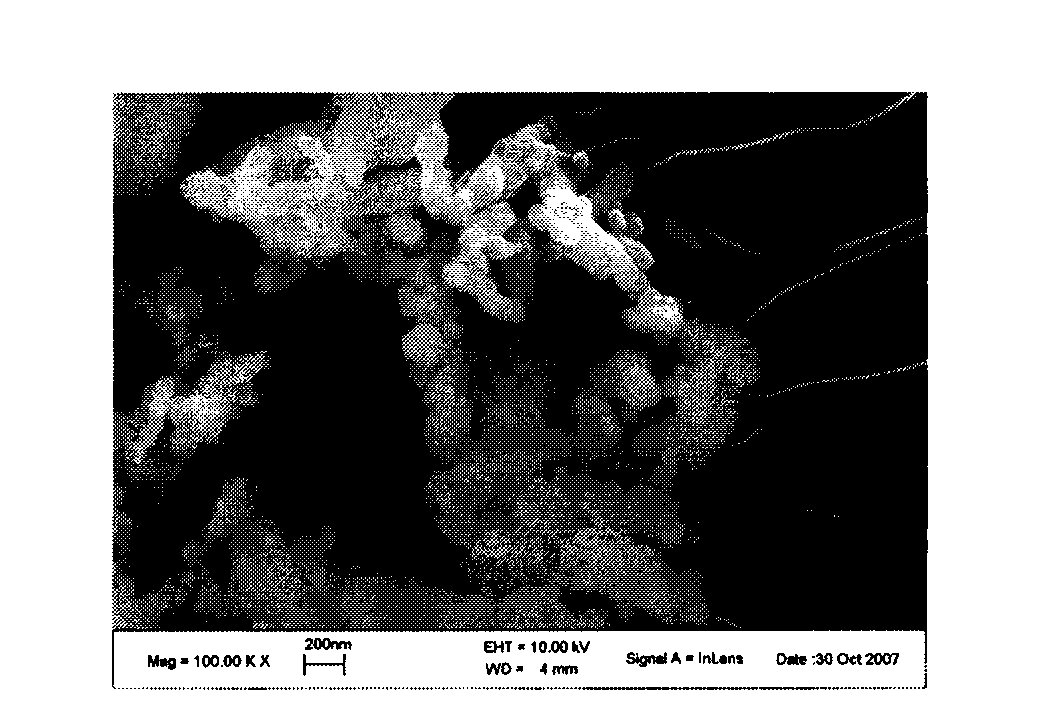

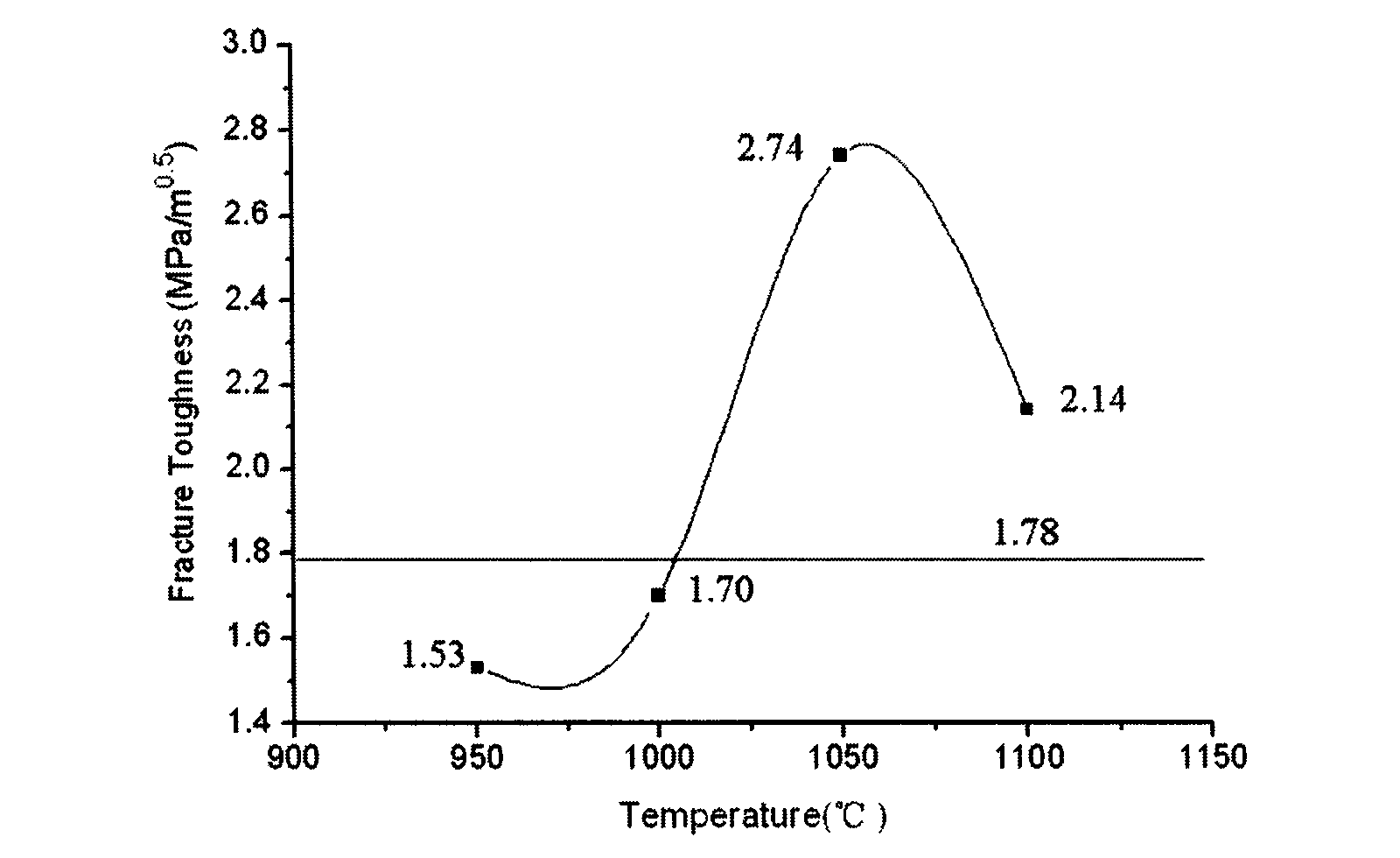

[0019] 1. First, the nano-SrCO 3 and Fe 2 o 3 Dosing is carried out according to the mole percentage of 1:5.9, and then ball milling is carried out with agate balls in an ethanol environment, so as to achieve the purpose of fully mixing and refining the raw material powder. Then the ball-milled raw materials are dried, sieved, and placed in a high-temperature furnace for solid-state reaction. Air atmosphere is used for sintering, and the final sintering temperature of isostatic pressure in high-temperature furnace is 950 ° C ~ 1200 ° C, and the temperature is kept for 12 hours;

[0020] 2. The synthesized SrFe 12 o 19 The powder is subjected to secondary ball milling, and then the milled powder is dried and sieved, and finally sintered by isostatic sintering at a sintering temperature of 950°C to 1050°C and kept for 2 hours. Obtain the maximum fracture toughness of sample at this moment to be 2.74;

[0021] On the basis of the above-mentioned technical scheme, D3021, whi...

Embodiment 2

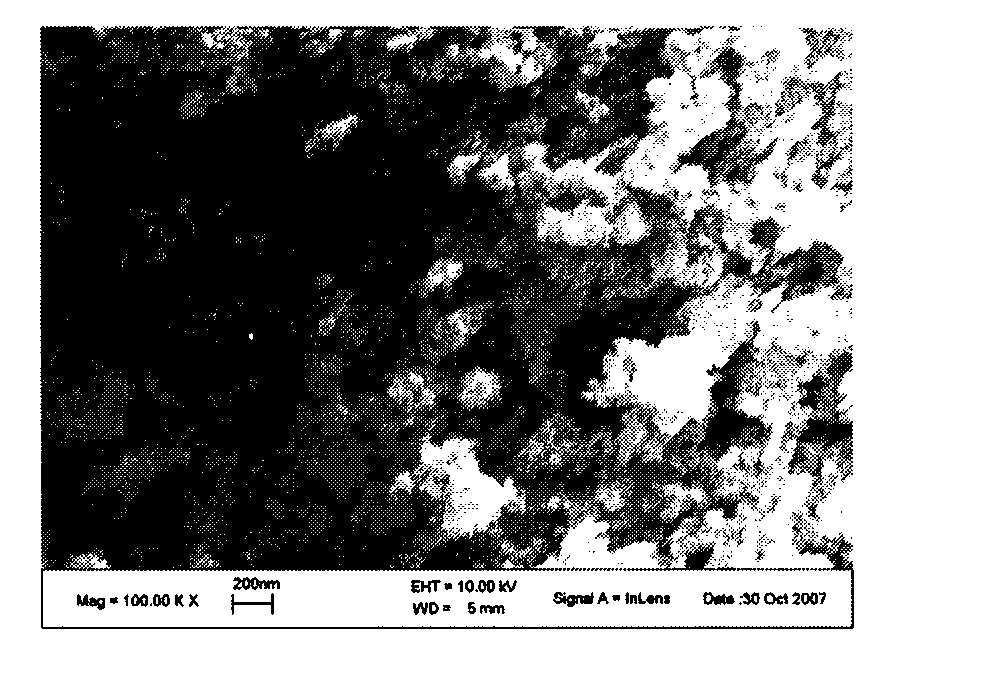

[0023] 1. Nano-SrCO 3 and Fe 2 o 3 Dosing is carried out according to the molar percentage of 1:5.6, and then ball milling is carried out with agate balls in an ethanol environment, so as to achieve the purpose of fully mixing and refining the raw material powder. Then the ball-milled raw materials are dried, sieved, and placed in a high-temperature furnace for solid-state reaction. An air atmosphere is used during sintering, and the final sintering temperature of isostatic pressing in a high-temperature furnace is 950° C. to 1200° C., and the temperature is kept for 12 to 13 hours.

[0024] 2. The synthesized SrFe 12 o 19 The powder is subjected to secondary ball milling, and then the ball milled powder is dried and sieved. Finally, sintering is carried out by means of isostatic sintering, the highest sintering temperature is 1150° C., and the temperature is kept for 2 hours. At this time, the maximum fracture toughness of the sample obtained was 2.14.

[0025] On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com