Method for producing steel/aluminum composite conductive pole

A technology of aluminum composite and conductive pillars, which is applied in the direction of contact manufacturing and connecting contact materials, etc., can solve the problems of poor interface bonding and other problems, and achieve the effects of strong follow-up development, high bonding strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

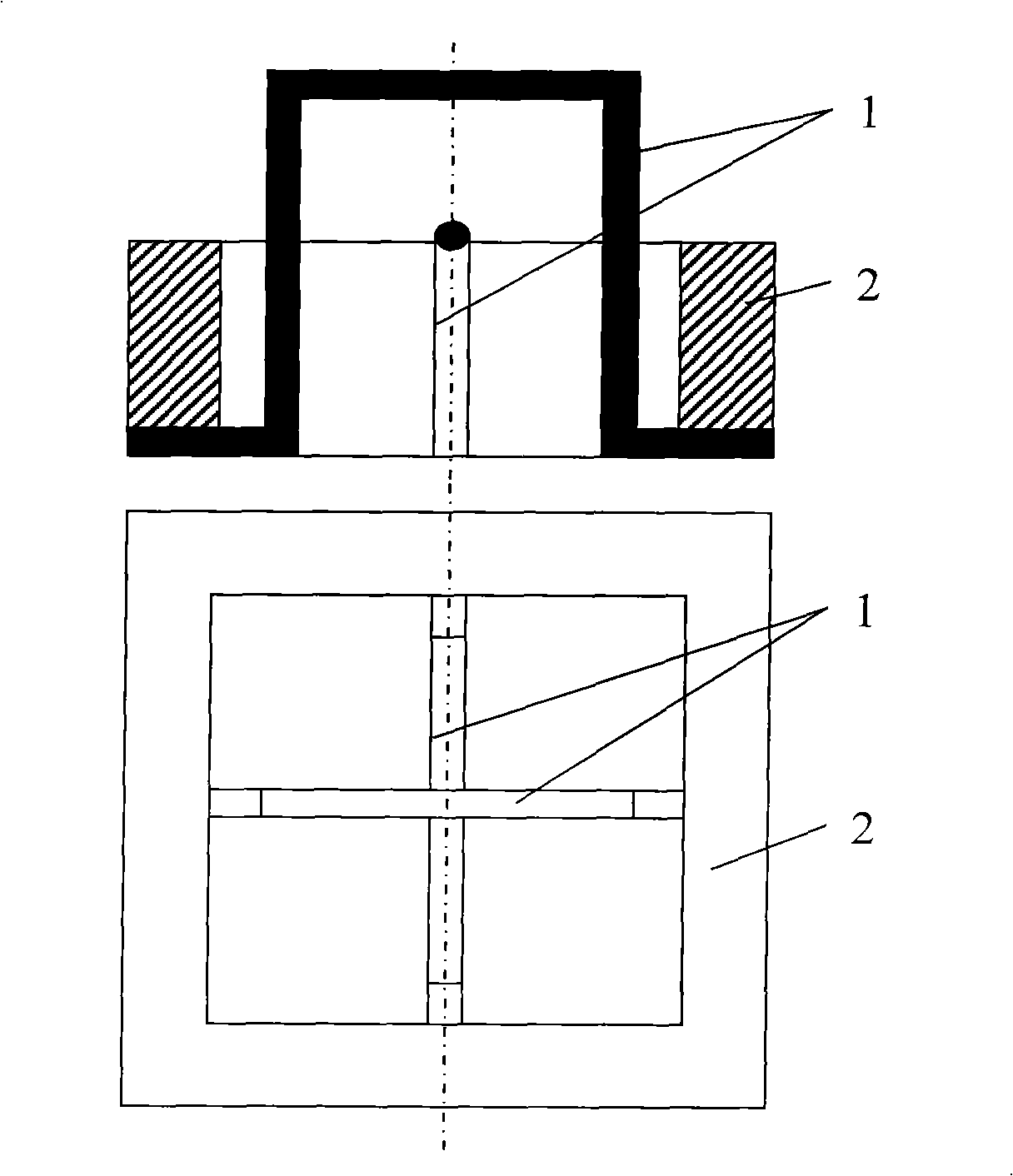

[0023] In the design process of the steel head, the steel head adopts a square hole structure, the outer size of the main body of the steel head is 130mm×130mm×60mm, and the size of the inner hole ensures that the ratio of the area of the steel to the area of the aluminum at the same height of the steel / aluminum composite part is 1:1.5 ; Weld two cross reinforcement ribs at the bottom of the steel head, with a diameter of 10mm, one with a height of 60mm, and the other with a height of 80mm. figure 1 A schematic diagram of the steel head structure. Before pouring, the part of the steel head that needs to be in contact with the aluminum water is subjected to high-temperature baking, oxidation degreasing, sandblasting and rust removal, and then surface pretreatment with potassium fluorozirconate aqueous solution. The temperature of the potassium fluorozirconate aqueous solution is kept at 80°C; The final steel head was heated at 450°C for 25 minutes; the pouring temperature o...

Embodiment 2

[0025] In the design process of the steel head, the steel head adopts a square hole structure, the outer size of the main body is 150mm×150mm×70mm, and the size of the inner hole ensures that the area ratio of the steel area to the aluminum area at the same height of the steel / aluminum composite part is 1:2.0; The bottom of the steel head is welded with reinforcing ribs with a diameter of 13mm, one with a height of 70mm and the other with a height of 130mm. Before pouring, the part of the steel head that needs to be in contact with the aluminum water is first subjected to high-temperature baking, oxidation degreasing, sandblasting and rust removal, and then surface pretreatment with potassium fluorozirconate aqueous solution. The temperature of the potassium fluorozirconate aqueous solution is kept at 80 °C; The treated steel head is heated at 430°C for 30 minutes; the pouring temperature of the aluminum water is controlled at 770°C; after the aluminum water is poured, keep coo...

Embodiment 3

[0027] In the design process of the steel head, the steel head adopts a square hole structure, the outer size of the main body is 160mm×160mm×80mm, and the size of the inner hole ensures that the ratio of the area of the steel to the area of the aluminum at the same height of the steel / aluminum composite part is 1:2.6; The bottom of the steel head is welded with reinforcing ribs, the diameter is 16mm, one is 80mm high, and the other is 180mm high; before pouring, the part of the steel head that needs to be in contact with aluminum water is degreased with high alkali, pickled and derusted, and rinsed with clean water Then use potassium fluorozirconate aqueous solution for surface pretreatment. The temperature of potassium fluorozirconate aqueous solution is kept at 85°C; the treated steel head is heated at 400°C for 35 minutes; the pouring temperature of aluminum water is controlled at 750°C; the aluminum water is poured well Afterwards, keep cooling slowly near the steel he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com