Preparation method for assembling large-area ordered microsphere template by liquid level swirl method

A large-area, vortex technology, applied in the field of preparation of large-area ordered microsphere templates assembled by liquid surface vortex method, can solve the problems of difficult to obtain large-area ordered microsphere arrays, long preparation time, complicated process, etc., and achieve raw materials Wide range of sources, simple preparation process, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

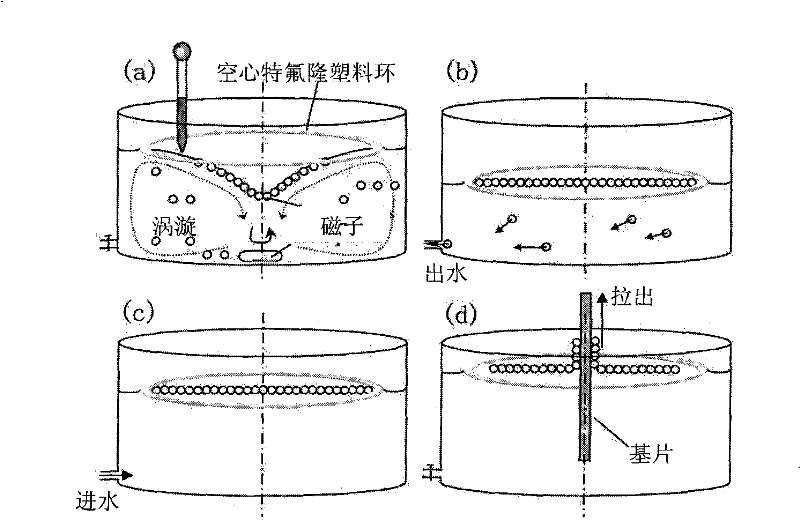

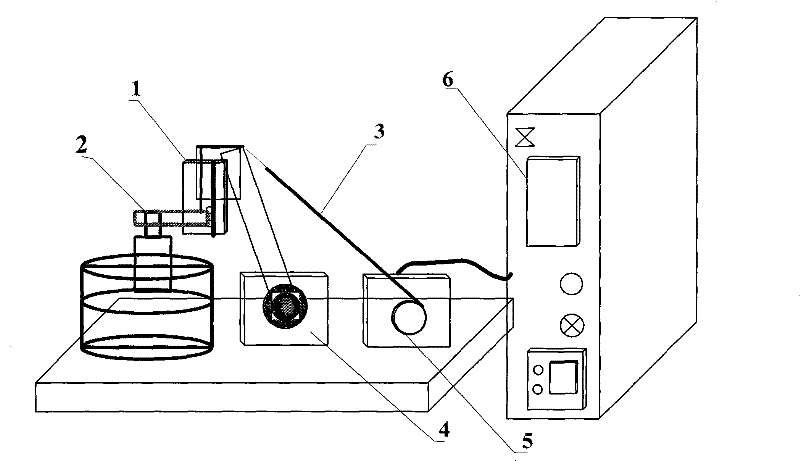

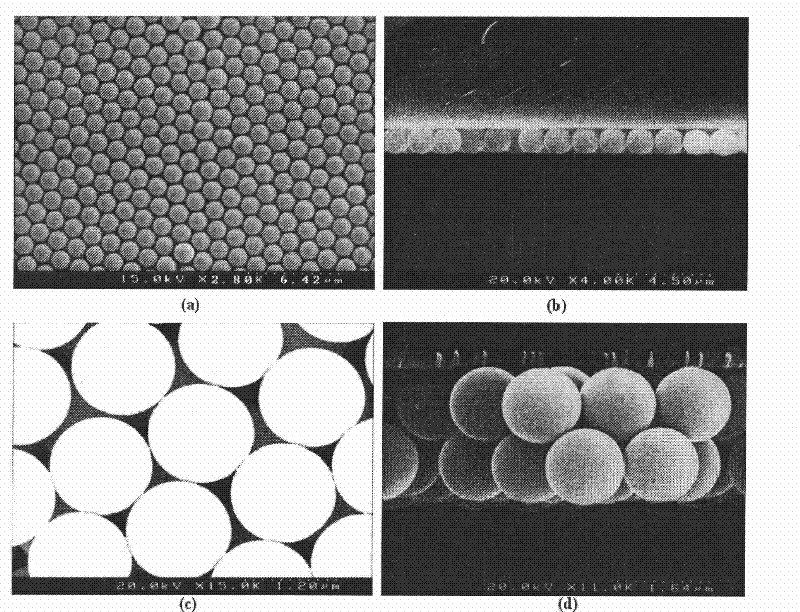

[0027] Add 49.5ml of ethanol, 4.88ml of water and 1g of PVP mixed solution into a 250ml three-necked flask, heat it in a water bath to 70°C, pass in nitrogen protection, stir for a certain period of time, and then add 5.5ml of washed styrene by one-time pouring 1. Initiator AIBN 0.05g, after reacting for 24 hours, take out the emulsion and centrifuge, discard the supernatant, use ethanol to ultrasonically wash, repeat several times, and collect the final emulsion for later use. Characterized by scanning electron microscopy, the particle size of the prepared microspheres was 1.33 μm. Inject a certain amount of ultrapure water into an open container, and place a clean hollow Teflon plastic ring on the water surface. Use the stirring of the magnet to generate a stable vortex on the water surface, and slowly drop the PS microsphere emulsion dispersed with ethanol on the surface of the swirling deionized water until a dense PS microsphere film is formed on the surface of the water....

Embodiment 2

[0029]Add 91.14ml of ethanol and 0.81g of PVP mixed solution into a 250ml three-necked flask, heat it in a water bath to 70°C, pass through nitrogen protection, stir for a certain period of time, and add 30.87ml of washed styrene at a dropping rate of 99.53μL / s 1. Initiator AIBN 0.28g, after reacting for 24 hours, take out the emulsion and centrifuge, discard the supernatant, use ethanol to ultrasonically wash, repeat several times, and collect the final emulsion for later use. Characterized by scanning electron microscopy, the particle size of the prepared microspheres was 5.21 μm. Inject a certain amount of ultrapure water into an open container, and place a clean hollow Teflon plastic ring on the water surface. Use the stirring of the magnet to generate a stable vortex on the water surface, and slowly drop the PS microsphere emulsion dispersed with ethanol on the surface of the swirling deionized water until a dense PS microsphere film is formed on the surface of the water....

Embodiment 3

[0031] Add 86.08ml of ethanol and 0.96g of PVP mixed solution into a 250ml three-necked flask, heat it in a water bath to 70°C, pass through nitrogen protection, stir for a certain period of time, then add 35.28ml of washed styrene at a rate of 87μL / s, Initiator AIBN 0.32g, after 24 hours of reaction, take out the emulsion and centrifuge, discard the supernatant, use ethanol to ultrasonically wash, repeat several times, and collect the final emulsion for later use. Characterized by scanning electron microscopy, the particle size of the prepared microspheres was 7.09 μm. Inject a certain amount of ultrapure water into an open container, and place a clean hollow Teflon plastic ring on the water surface. Use the blowing pipe to adjust the angle to blow to the water surface to generate a stable vortex, and slowly drop the PS microsphere emulsion dispersed with ethanol on the surface of the swirling deionized water until a dense PS microsphere film is formed on the surface of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com