Chromium based diamond composite chrome plating coating piston ring and method of processing the same

A piston ring and diamond technology, applied in the field of piston rings, can solve the problems of high brittleness of the coating, low content of diamond particles, falling off under force, etc., and achieve the effect of improving wear resistance and tensile cylinder performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

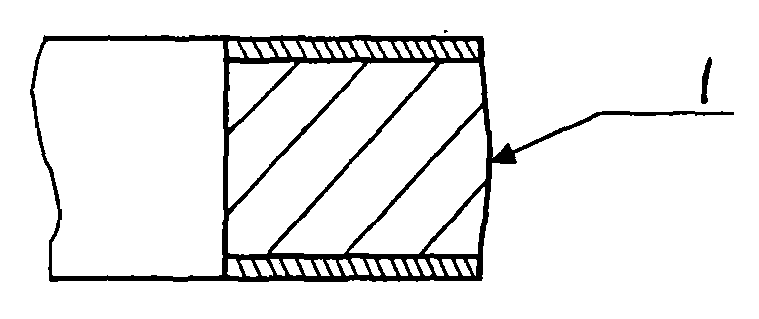

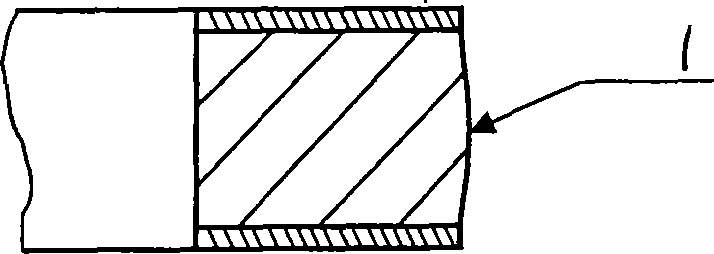

Image

Examples

Embodiment 1

[0023] Take a piston ring with a diameter of φ60 mm, and put it in 1000 liters of chromium plating solution, including 250 grams / liter of chromic anhydride, 2.5 grams / liter of sulfuric acid, 3 grams / liter of trivalent chromium, appropriate amount of catalyst A, current density of 70A / square decimeter, plating time For 15 minutes, first coat a layer of 25 micron hard chromium; process the chromium layer texture by physical and chemical method, with a density of 120 strips / mm, a width of 2.5 microns, and a depth of 11 microns; diamond particles are embedded in the mesh and fixed, and the particle size of the diamond particles is 0.05-8.0 Micron; in 1000 liters of chrome plating solution (250 g / L of chromic anhydride, 2.5 g / L of sulfuric acid, 3 g / L of trivalent chromium, 1 g / L of potassium fluorosilicate, 1 g / L of potassium methanesulfonate, current The density is 70A / square decimeter, the electroplating time is 3 minutes, and the sealing is carried out; then repeat 25 times from...

Embodiment 2

[0025] Take a piston ring with a diameter of φ300 mm, and put it in 1000 liters of chromium plating solution, including 350 grams / liter of chromic anhydride, 4 grams / liter of sulfuric acid, 4 grams / liter of trivalent chromium, 2 grams / liter of potassium fluorosilicate, and 3 grams / liter of potassium methanesulfonate. g / L, current density 40A / square decimeter, electroplating time 40 minutes, first plate a layer of 50 micron hard chromium; process the chromium layer texture by physical and chemical method, density 150 strips / mm, width 5 microns, concentration 20 microns; The particles are embedded in the mesh and fixed, and the particle size of the diamond particles is 0.05-2.0 microns; in 1000 liters of chrome plating solution (350 g / L of chromic anhydride, 4 g / L of sulfuric acid, 4 g / L of trivalent chromium, and 2 g / L of potassium fluorosilicate gram / liter, potassium methanesulfonate 3 grams / liter) current density 100A / square decimeter, electroplating time 2 minutes, seal; Repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com