Method for preparing negative electrode material by biotite modified by lithium ion exchange method

A negative electrode material, biotite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as poor electrical properties of biotite, achieve abundant reserves, fast speed, and improved specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing negative electrode materials by modifying biotite by lithium ion exchange method is provided, which specifically includes the following steps:

[0035] 1) After the biotite ore is pulverized with a ball mill, pass through a 200-mesh sieve;

[0036] 2) The biotite ore powder obtained in step 1) is uniformly mixed with the lithium nitrate aqueous solution of 0.77mol / L, wherein the mass volume ratio of the biotite ore powder and the lithium nitrate aqueous solution is 1g:250ml, and the molar concentration is 0.5mol / L dilute hydrochloric acid solution to adjust the pH value of the mixed solution to 1.5, then place the mixed solution in a constant temperature water bath at 80°C for stirring, filter the mixed solution after reacting for 5 hours, collect the solid insolubles and dry them to obtain the hydrated lepidolite negative electrode material.

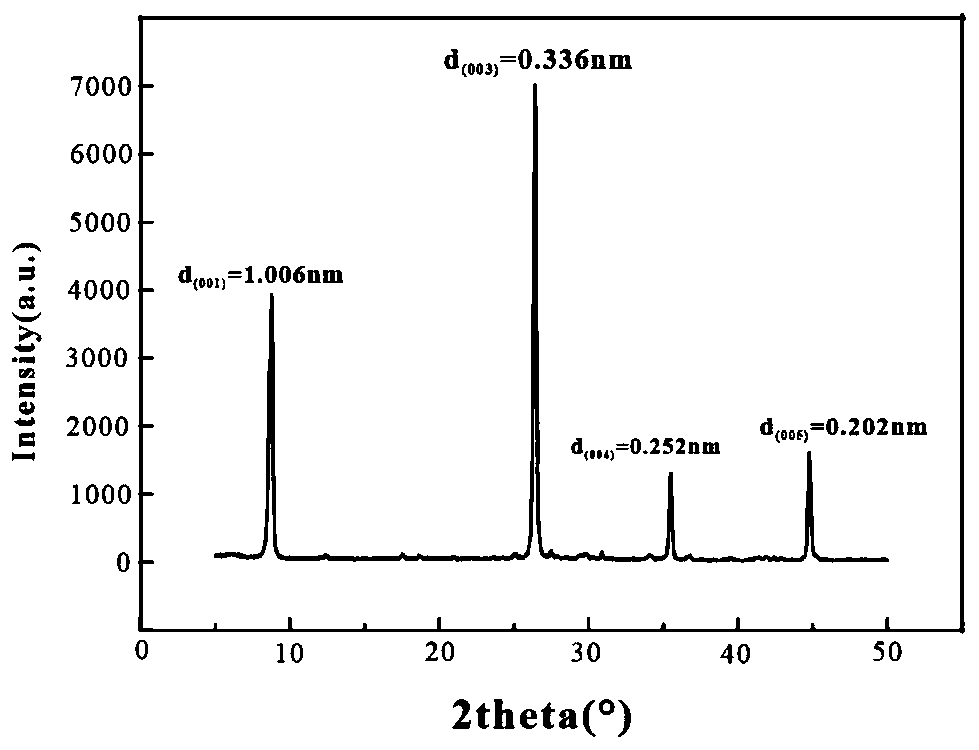

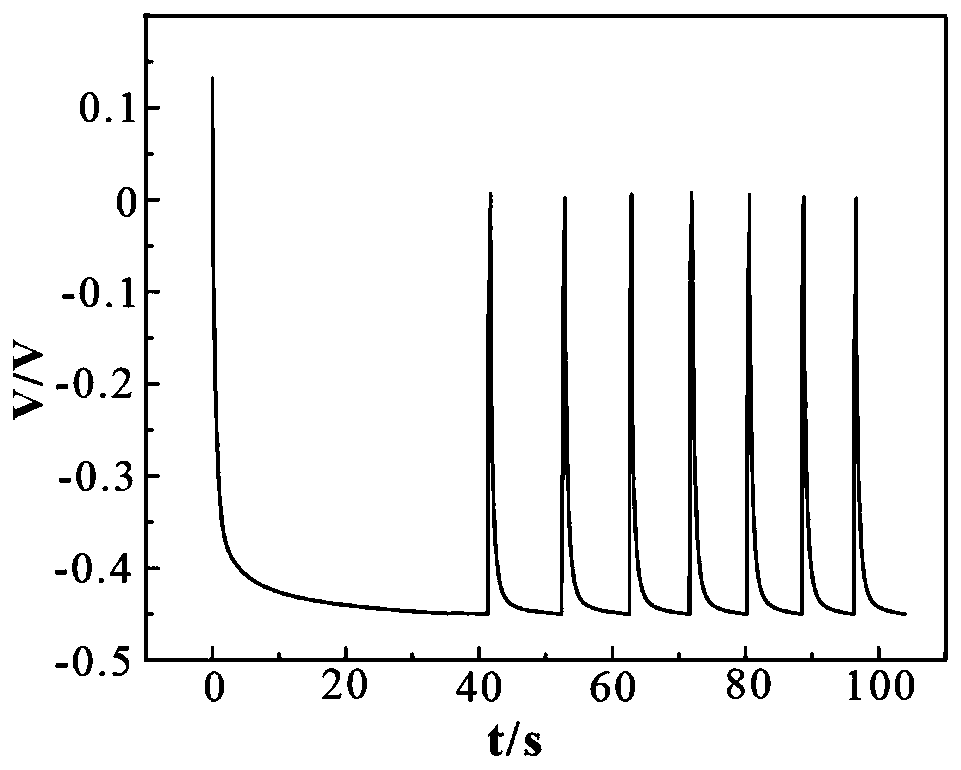

[0037] figure 1 and image 3 are the XRD patterns of biotite raw ore and the hydrated lepidolite negat...

Embodiment 2

[0041] A method for preparing negative electrode materials by modifying biotite by lithium ion exchange method is provided, which specifically includes the following steps:

[0042] 1) After the biotite ore is pulverized with a ball mill, pass through a 200-mesh sieve;

[0043] 2) The biotite ore powder obtained in step 1) is uniformly mixed with the lithium nitrate aqueous solution of 0.77mol / L, wherein the mass volume ratio of the biotite ore powder and the lithium nitrate aqueous solution is 1g:250ml, and the molar concentration is 0.5mol / L dilute hydrochloric acid solution to adjust the pH value of the mixed solution to 1.5, then place the mixed solution in a constant temperature water bath at 80°C for stirring, filter the mixed solution after reacting for 10 hours, collect the solid insolubles and dry them to obtain the hydrated lepidolite negative electrode material.

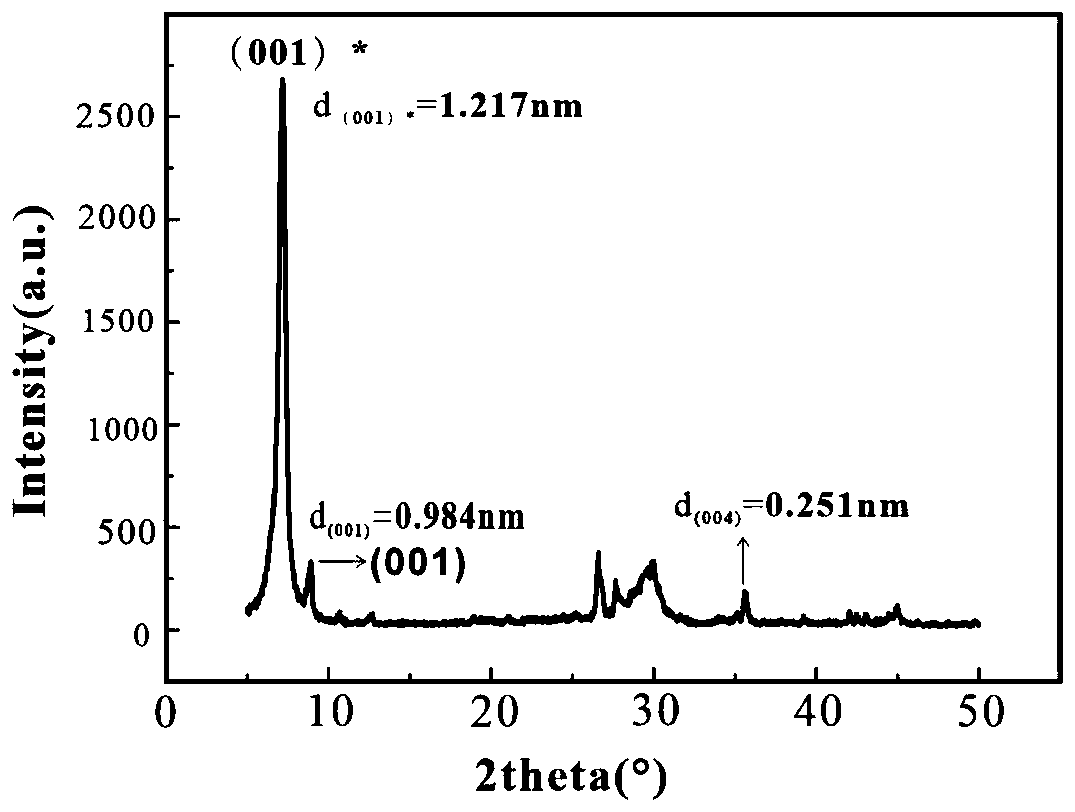

[0044] Figure 5 The X-ray diffraction pattern (XRD) of the hydrated lepidolite negative electrode mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com