Magnetic graphite phase carbon nitride material, and preparation method and applications thereof

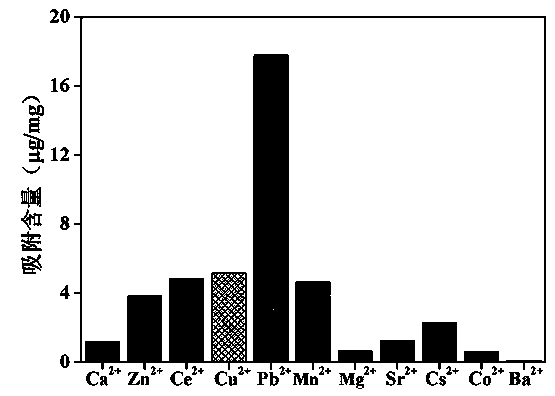

A graphite phase carbon nitride and magnetic technology, which is applied in the field of analysis and detection, can solve the problems of long separation time, poor selectivity, and poor safety, and achieve the effect of increasing specific surface area and good selective adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

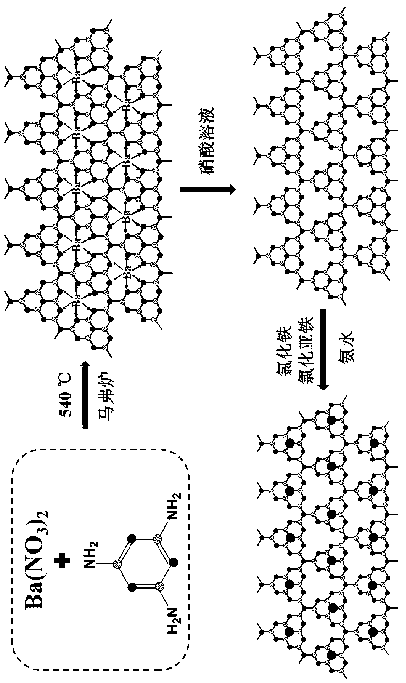

[0042] Example 1 as figure 1 Shown, a kind of preparation method of magnetic graphite phase carbon nitride material comprises the following steps:

[0043] (1) Mix 30g urea with 1g BaCl 2 After mixing, dissolve in ultrapure water with 1 times the mass of the mixture, stir at room temperature to fully dissolve, and obtain a triazine structure compound solution containing barium ions.

[0044] (2) Place the triazine structure compound solution containing barium ions in a vacuum drying oven at 60° C. and dry until anhydrous to obtain a white solid.

[0045] (3) The white solid was transferred to a crucible, placed in a muffle furnace, and calcined at a high temperature for 5 hours at a heating rate of 4 °C / min and a temperature of 500 °C to prepare barium ion-doped graphite phase nitride by thermal condensation Carbon material; after the reaction, cool to room temperature to obtain light yellow solid powder.

[0046] (4) Add 0.1 mol / L nitric acid solution to the light yellow ...

Embodiment 2

[0057] Embodiment 2 A kind of preparation method of magnetic graphite phase carbon nitride material comprises the following steps:

[0058] (1) Mix 5g melamine with 1g Ba(NO 3 ) 2 After mixing, dissolve in ultrapure water 3 times the weight of the mixture, stir at room temperature to fully dissolve, and obtain a triazine structure compound solution containing barium ions.

[0059] (2) Place the solution of the triazine structure compound containing barium ions in a vacuum drying oven at 80° C. to dry to anhydrous to obtain a white solid.

[0060] (3) The white solid was transferred to a crucible, placed in a muffle furnace, and calcined at a high temperature for 3 hours at a heating rate of 4 °C / min and a temperature of 580 °C to prepare barium ion-doped graphite phase nitride by thermal condensation Carbon material; after the reaction, cool to room temperature to obtain light yellow solid powder.

[0061] (4) Add 2.0 mol / L nitric acid solution to the light yellow solid pow...

Embodiment 3

[0072] Embodiment 3 A kind of preparation method of magnetic graphite phase carbon nitride material, comprises the following steps:

[0073](1) Mix 10g cyanamide with 0.5g Ba(CH 3 COO) 2 After mixing, dissolve in ultrapure water twice the mass of the mixture, stir at room temperature to fully dissolve, and obtain a triazine structure compound solution containing barium ions.

[0074] (2) Place the triazine structure compound solution containing barium ions in a vacuum drying oven at 70° C. and dry until anhydrous to obtain a white solid.

[0075] (3) The white solid was transferred to a crucible, placed in a muffle furnace, and calcined at a high temperature for 4 hours at a heating rate of 4 °C / min and a temperature of 520 °C to prepare barium ion-doped graphite phase nitride by thermal condensation Carbon material; after the reaction, cool to room temperature to obtain light yellow solid powder.

[0076] (4) Add 1.0 mol / L acetic acid solution to the light yellow solid pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

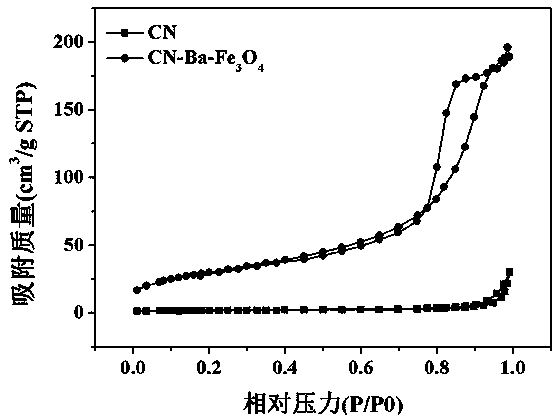

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com