X-ray fluorescence spectrum analysis method for continuous casting mold flux

A technology of continuous casting mold slag and fluorescence spectroscopy, which is applied in the field of analysis, can solve problems affecting analysis accuracy, chemical composition correction, matrix inconsistency, etc., to improve analysis speed and accuracy, improve analysis accuracy, and enhance industrial applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

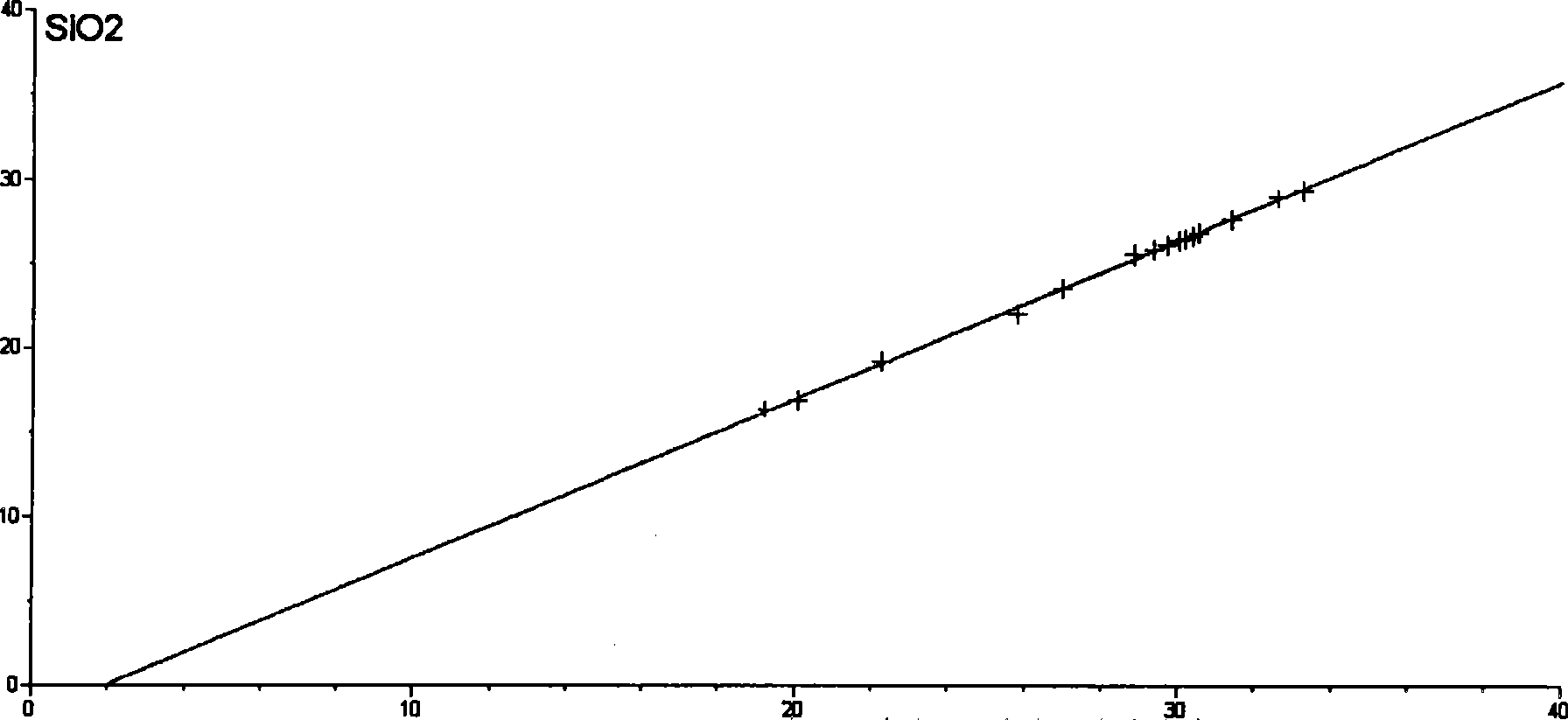

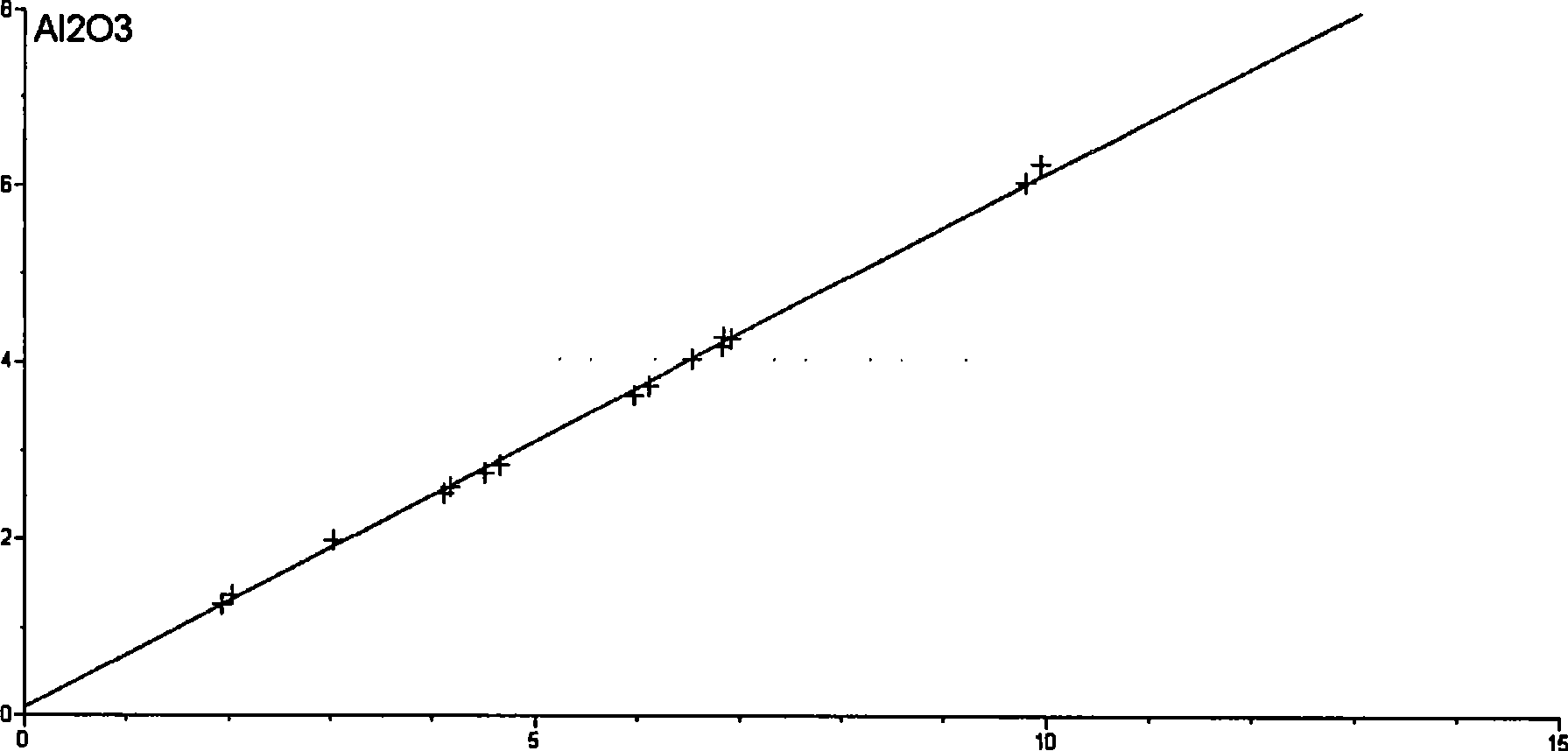

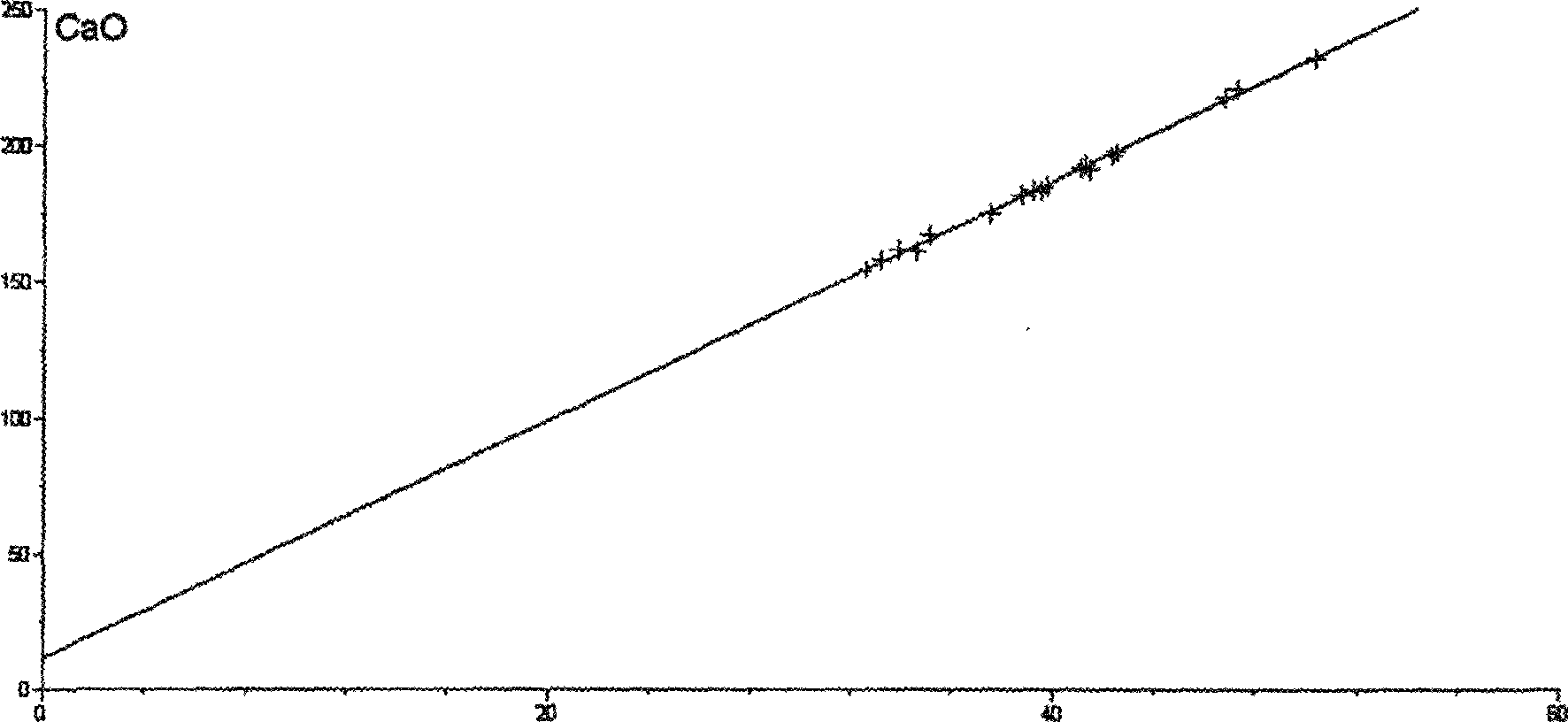

Image

Examples

Embodiment 1

[0017] Example 1: This example is applied to the component analysis of three mold flux samples in production.

[0018] Selection of standard samples: The calibration samples are synthetic standard samples made by mixing blast furnace slag standard samples, fluorite standard samples, and coke component standard samples in the following proportions. The content of each element in the synthetic standard sample covers the entire range of mold powder components, forming a standard sample group in which each element contained in the tested sample has a certain concentration gradient.

[0019] 1) The three types of standard components required for the preparation of mixed standard samples are as follows:

[0020] serial number Standard type country number SiO 2 Al 2 o 3 CaO MgO CaF 2 1 blast furnace slag 93-55 34.93 12.94 39.55 7.95 -- 2 blast furnace slag 512 39.95 7.64 41.55 8.07 -- 3 blast furnace slag 513 40.66 8.28 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com