Method for decomposing dinitrogen monoxide

A nitrous oxide and catalyst layer technology, which is applied in the direction of nitrous oxide capture, separation methods, chemical instruments and methods, etc., to achieve the effects of reducing equipment costs, reducing global warming substances, and simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

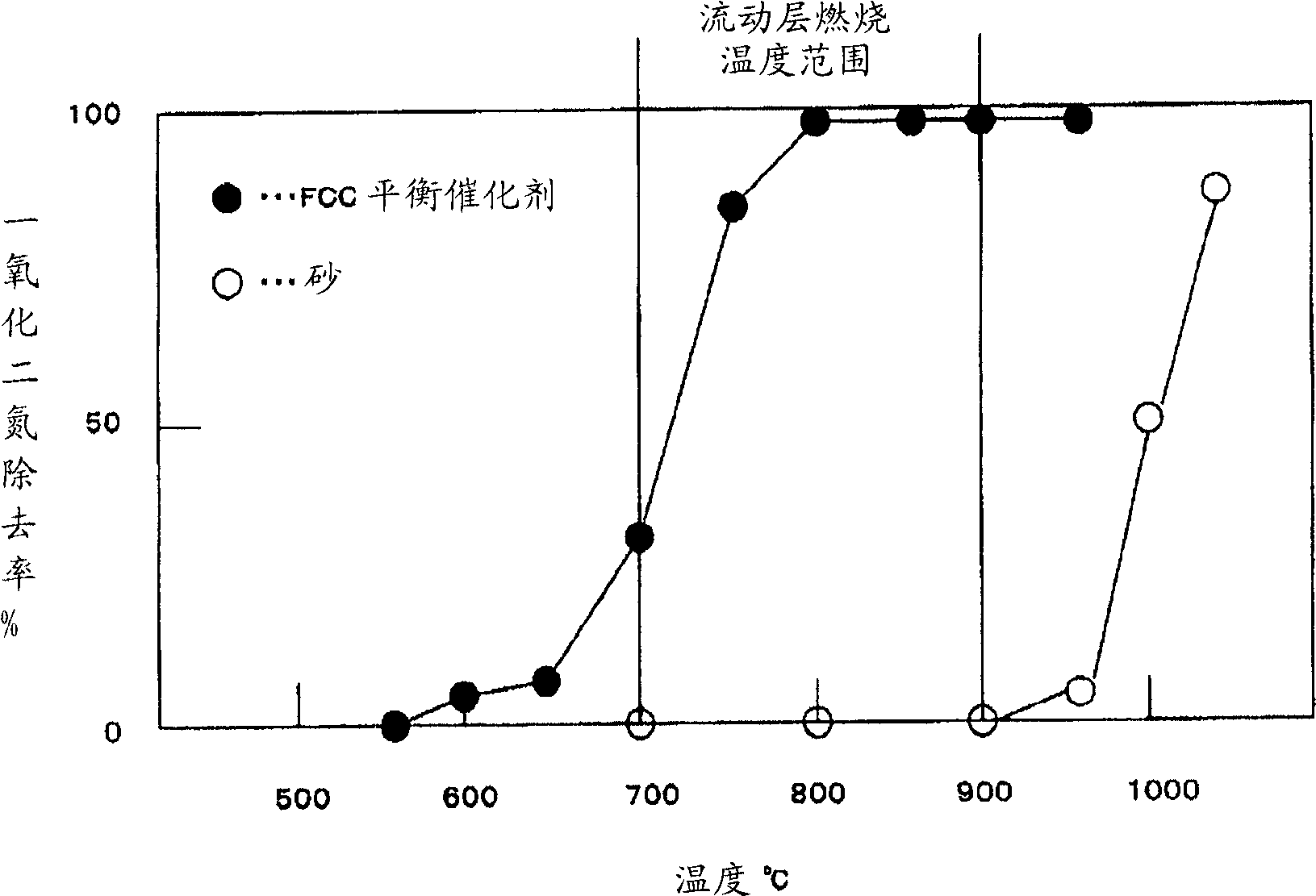

[0053] As the FCC equilibrium catalyst, a compound containing 10% by mass of rhenium-substituted ultrastable Y-type zeolite, 40% by mass of alumina, 30% by mass of silica, and 20% by mass of the clay mineral kaolin extracted from the actual plant of FCC (real plant) was used. An FCC equilibrium catalyst in which rhenium is substituted for ultrastable Y-type zeolite and 520 mass ppm of vanadium and 280 mass ppm of nickel are accumulated.

[0054] Use this FCC equilibrium catalyst (particles with a particle size of 0.080 to 0.3mm) for N 2 O decomposition experiment.

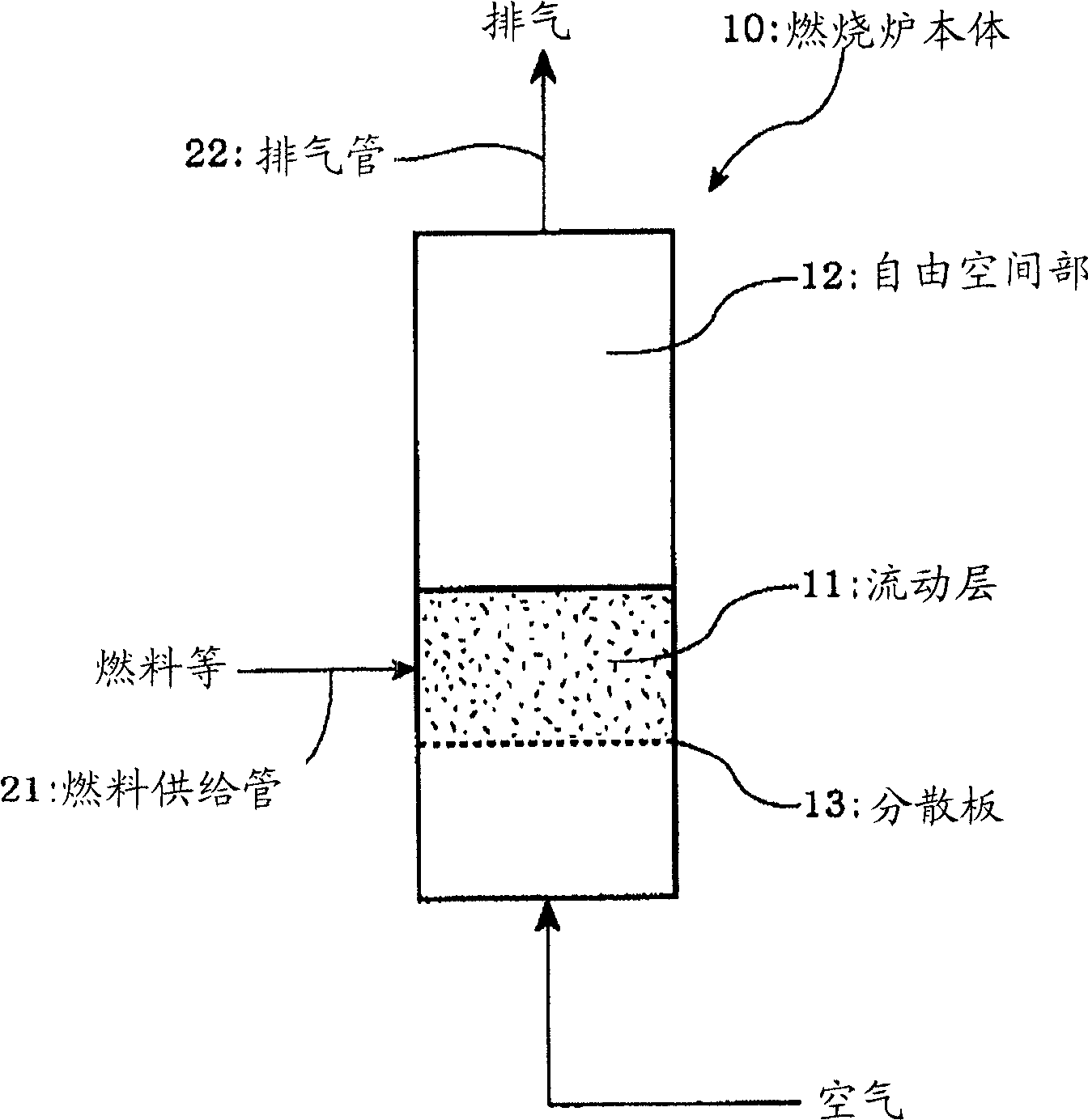

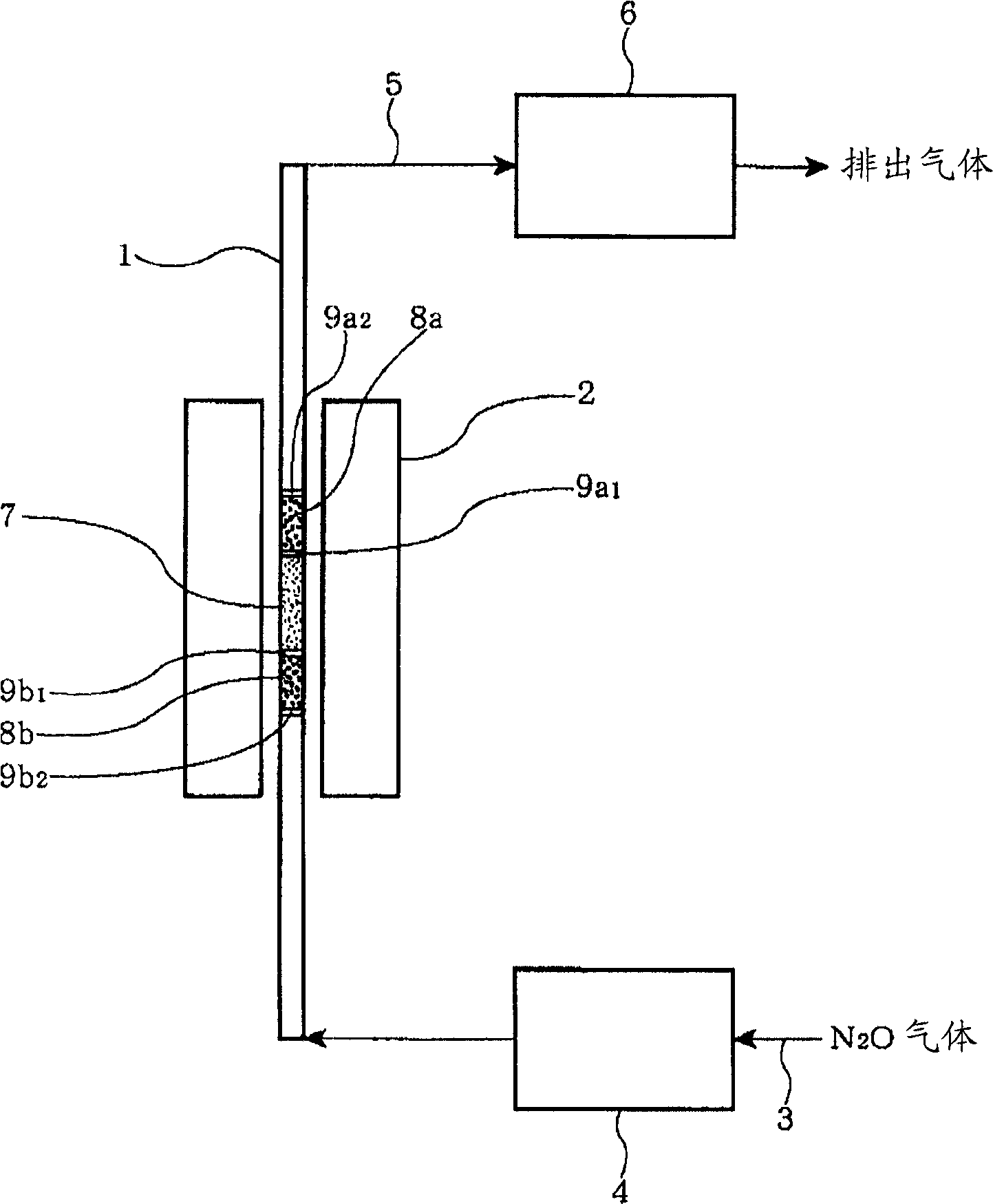

[0055] used in this experiment figure 2 device shown. This device has the quartz tube 1 that inner diameter is 6mm, the electric furnace 2 that surrounds the central part of the length direction of the quartz tube 1, the N that is connected with the bottom of the quartz tube 1 2 O gas inlet pipe 3, set in N 2 N in the middle of the O gas introduction pipe 3 2 O gas flow meter 4, the gas discharge pipe 5 that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com