Method for extracting soy protein, oligosaccharide and isoflavone from soybean whey by two-stage two-segment film

A technology of soybean protein and soybean yellow, which is applied to the preparation methods of oligosaccharides and peptides, chemical instruments and methods, etc., to achieve the effects of reducing environmental pollution, short process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

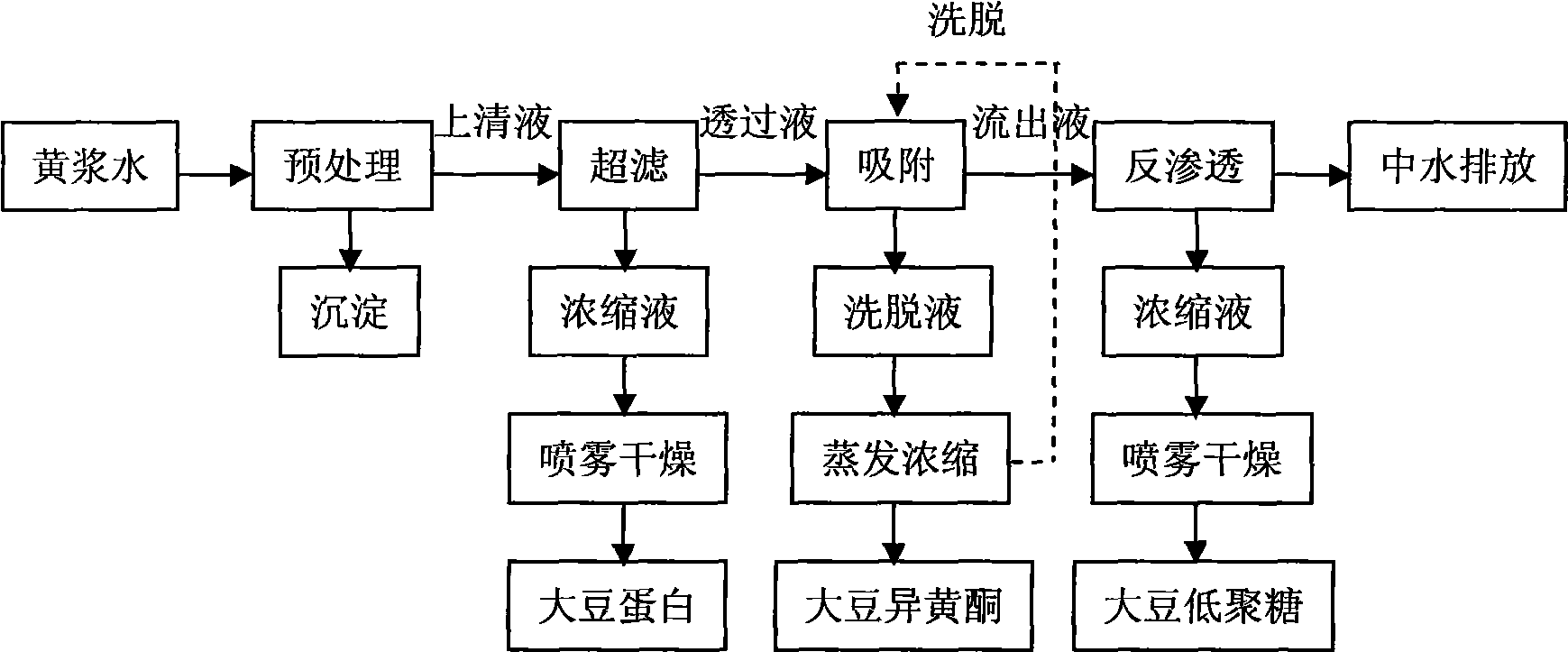

[0027] see figure 1 The method for extracting soybean protein, oligosaccharides and isoflavones from soybean yellow pulp water by secondary two-section membrane comprises the following steps:

[0028] Step 1: Preprocessing

[0029] Collect the soybean yellow slurry water produced in the production process of soybean products to the waste water tank, and enter the disc centrifuge with a speed of more than 10000r / min and a flow rate of 2L / min through a waste water booster pump for centrifugation pretreatment, and the centrifugation temperature is 10- 60°C to remove the bean dregs, particles, suspended matter, etc., to obtain the supernatant A;

[0030] Step 2: Ultrafiltration

[0031] The supernatant A obtained after pretreatment is passed through a one-stage ultrafiltration membrane system with a molecular weight cut-off of 50,000-100,000 Daltons at a temperature of 20-50°C and a pressure of 0.5-1.5Mpa to obtain soybean protein concentrate P1 A , and get ultrafiltration memb...

Embodiment 2

[0038] Step 1: Preprocessing

[0039]Take 1000L of soybean yellow slurry water and add it to a disc centrifuge with a rotation speed of 20000r / min or more and a flow rate of 2L / min for centrifugation pretreatment. The centrifugation temperature is 10-60°C to remove the bean dregs, particles, suspended solids, etc., to obtain 974L supernatant A;

[0040] Step 2: Ultrafiltration

[0041] The supernatant A obtained after pretreatment is sequentially passed through a one-stage ultrafiltration membrane system with a molecular weight cut-off of 50,000-100,000 Daltons at 20-50°C and an operating pressure of 0.5-1.5Mpa to obtain soybean protein concentrate P1 A , and get ultrafiltration membrane permeate B 0 ; Then the ultrafiltration membrane permeate B 0 Soybean protein is separated from soy isoflavones and soybean oligosaccharides through a one-stage two-stage ultrafiltration membrane system with a molecular weight cut-off of 3000 Daltons, and soybean protein concentrate P1 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com