Chitosan / ion liquid conductive compound film and preparation thereof

A technology of ionic liquid and chitosan, which is applied in the field of polymers, can solve the problems of limiting the application of chitosan and poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

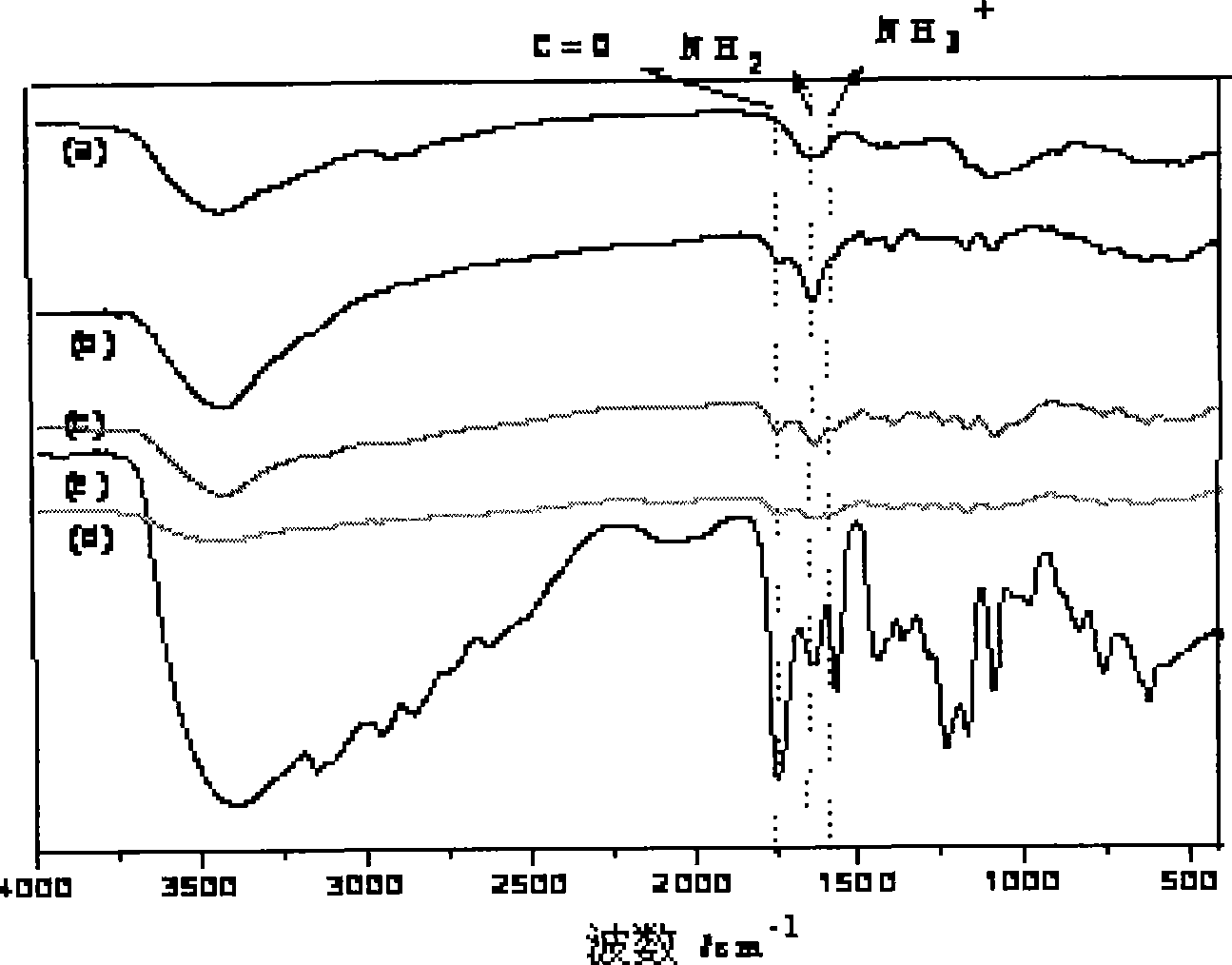

[0060] Embodiment 1, the preparation of chitosan / [CCIm]Cl composite conductive film

[0061] (1) Preparation of 1,4-diimidazolidine

[0062] Weigh 27.2 grams of imidazole (0.4mol) and dissolve in 48ml of toluene and 48ml of dimethyl sulfoxide mixed solution, then add 50% sodium hydroxide solution (containing 0.4mol of sodium hydroxide), connect the water separator and heat to 130 ~170°C, react until no water is generated, cool down; then move the reactor to an ice-water bath, slowly add 1,4-dibromobutane (0.2mol) dropwise at a rate of 3~5mL / min; Reaction 2 hours, a pale yellow solid was generated, and the toluene and dimethyl sulfoxide were removed by filtration to obtain a crude product.

[0063] The obtained crude product was dissolved in chloroform, sodium bromide was removed by filtration, and chloroform was distilled off under reduced pressure to obtain a reddish-brown liquid; 150 mL of distilled water was added thereto, mixed evenly, and left to stand for 12 hours to pr...

Embodiment 2

[0073] Embodiment 2, chitosan / [CCIm]CH 3 Preparation of COO Composite Conductive Film

[0074] (1) Preparation of 1,4-diimidazolidine

[0075] With embodiment 1.

[0076] (2) Chlorinated N, N'-dicarboxymethyl-1,4-diimidazolidine ionic liquid ([CCIm]CH 3 COO) preparation

[0077] With embodiment 1.

[0078] (3) Ionic liquid [CCIm]CH 3 Preparation of COO

[0079] Weigh 0.12 mol of sodium acetate and 0.1 mol of [CCIm]Cl and dissolve in 20 ml of acetonitrile, stir the mixed solution at room temperature for 48 hours, remove NaCl by filtration, evaporate the acetonitrile, wash the precipitate with 300 ml of diethyl ether three times, and finally obtain a white viscous Thick material, 92% yield.

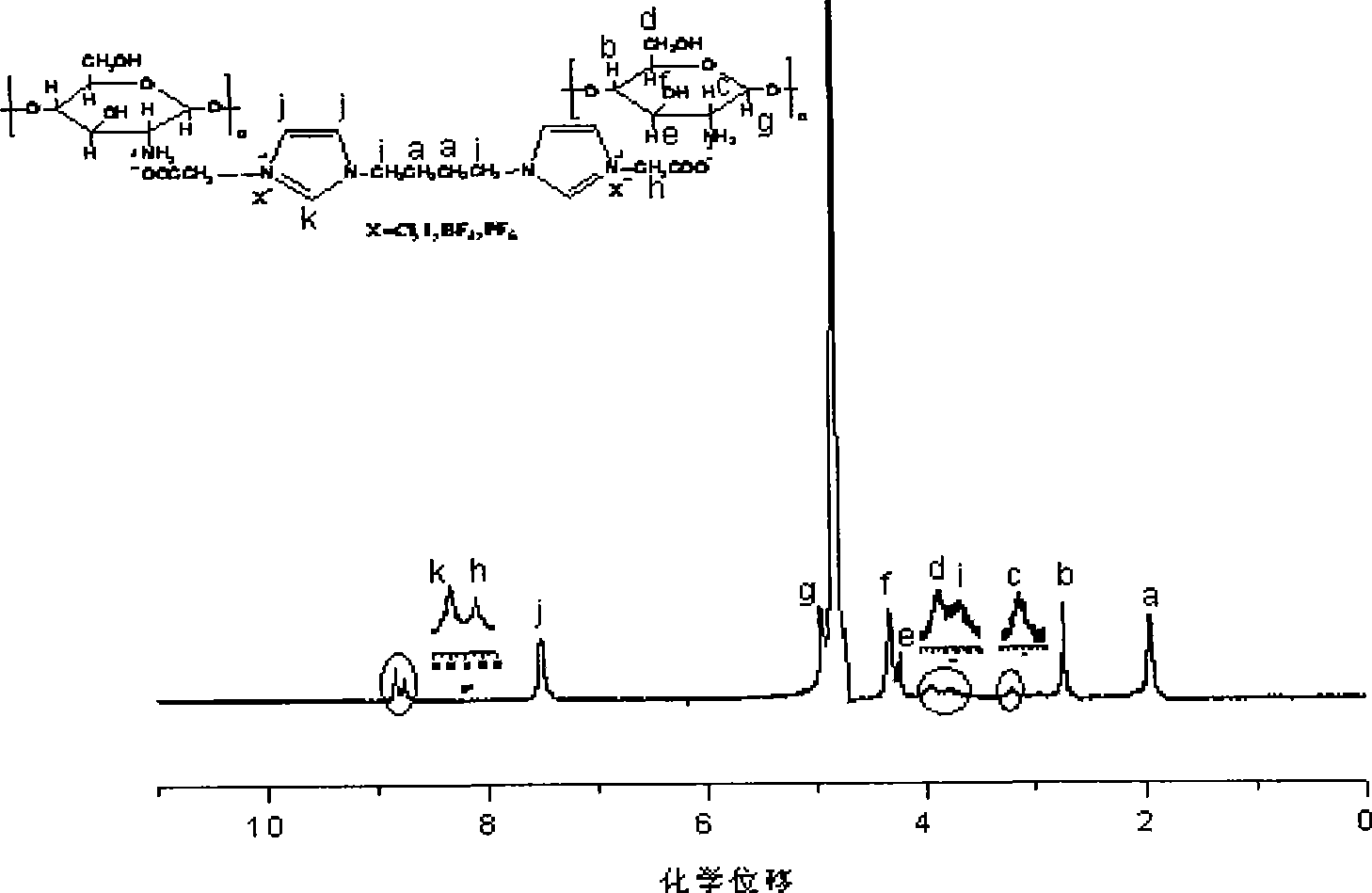

[0080] 1 H NMR (CD 3 OD, δ) 8.08 (s, 1, H 2 (Im)), 7.324-7.340 ((m, 1, H 5 (Im)), 7.088 (m, 1, H 4 (Im)), 3.83-3.87 (t, 4, NCH 2 CH 2 ), 2.495(t, 4, NCH 2 COOH), 1.648-1.709 (t, 4, NCH 2 CH 2 ).

[0081] (4) Chitosan / [CCIm]CH 3 Preparation of COO Composite Conductive Film ...

Embodiment 3

[0086] Embodiment 3, chitosan / [CCIm] BF 4 Preparation of Composite Conductive Film

[0087] (1) Preparation of 1,4-diimidazolidine

[0088] With embodiment 1.

[0089] (2) Preparation of chlorinated N, N'-dicarboxymethyl-1,4-diimidazolidine ionic liquid ([CCIm]Cl)

[0090] With embodiment 1.

[0091] (3) Ionic liquid [CCIm]BF 4 preparation of

[0092] Weigh 0.12 mol of sodium acetate and 0.1 mol of [CCIm]Cl and dissolve in 20 ml of acetonitrile, stir the mixed solution at room temperature for 48 hours, remove NaCl by filtration, evaporate the acetonitrile, wash the precipitate with 300 ml of diethyl ether three times, and finally obtain a white viscous Thick substance, yield 90.6%.

[0093] 1 H NMR (CD 3 OD, δ) 8.08 (s, 1, H 2 (Im)), 7.324-7.340 ((m, 1, H 5 (Im)), 7.088 (m, 1, H 4 (Im)), 3.83-3.87 (t, 4, NCH 2 CH 2 ), 2.495(t, 4, NCH 2 COOH), 1.648-1.709 (t, 4, NCH 2 CH 2 ).

[0094] (4) Chitosan / [CCIm]BF 4 Preparation of Composite Conductive Film

[0095] 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com