Method for preparing biodiesel from lipid under supercritical condition

A biodiesel and oil technology, which is applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve problems such as difficult industrial production, and achieve the effects of relatively mild reaction conditions, wide adaptability of raw materials, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, prepare biodiesel with grease

[0021] In the first step, 10 kilograms of grease, 6 grams of concentrated hydrochloric acid (36%wt) and methanol are mixed, wherein the mol ratio of methanol to grease is 40:1;

[0022] In the second step, react for 6 minutes at 240°C, pressure 10MPa, and stirring intensity 400r / min;

[0023] In the third step, the reaction is completed, and the solution is poured into a separatory funnel and allowed to stand overnight for stratification;

[0024] In the fourth step, take the upper layer solution and wash and dry it repeatedly to obtain 9.937KG of yellow, clear and transparent biodiesel.

Embodiment 2

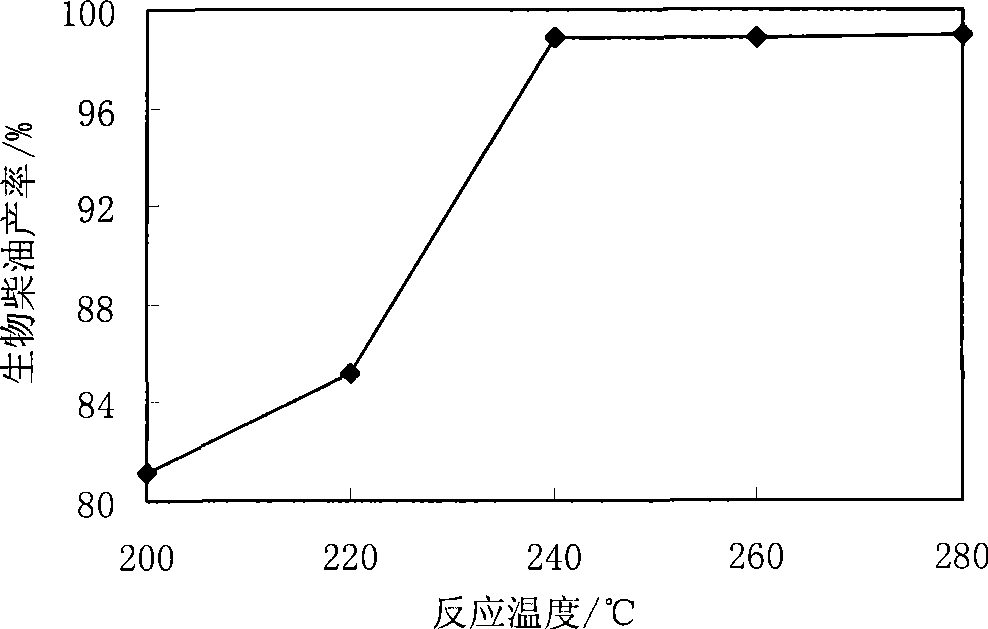

[0025] Embodiment 2, the influence of temperature of reaction on transesterification reaction

[0026] The present invention is implemented under the conditions of alcohol-oil molar ratio 40 / 1, reaction pressure 10MPa, catalyst consumption 0.06%, reaction time 6min stirring intensity 400r / min, the influence of different reaction temperatures on biodiesel yield is shown in figure 1 . from figure 1 It can be seen that the biodiesel yield increases with increasing temperature. As the temperature increases, the activity of the reactants increases, the reaction speed increases, and the yield of biodiesel increases. When the temperature reaches 240°C, methanol reaches the supercritical point, and the yield of biodiesel increases significantly. If the temperature continues to rise, the increase in biodiesel yield is not obvious. If the temperature is too high, the energy consumption and manufacturing cost of the equipment will be increased, and the unsafe factors will also be incr...

Embodiment 3

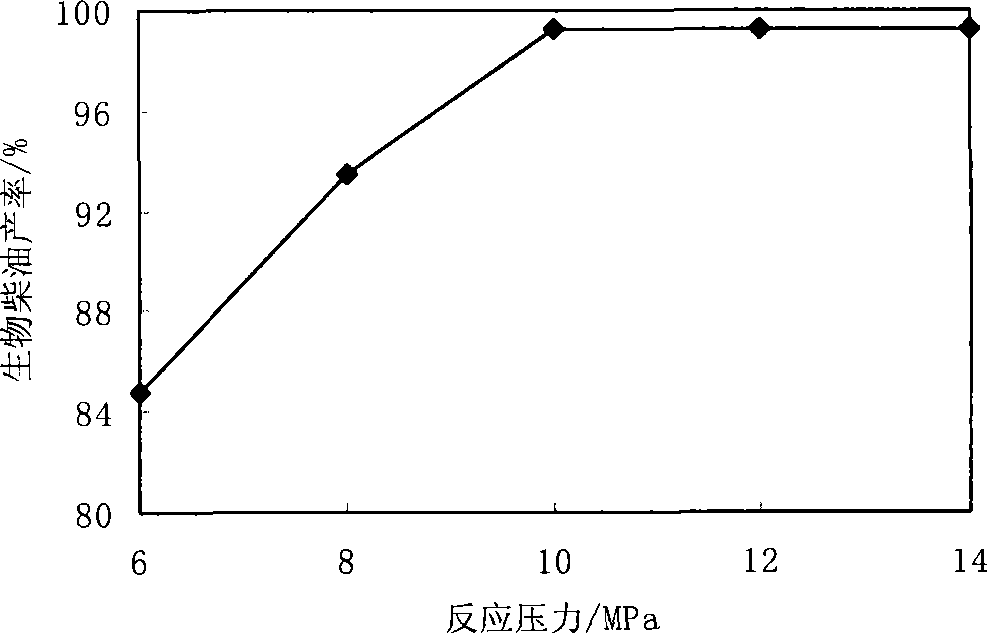

[0027] Embodiment 3, the influence of supercritical pressure on transesterification reaction

[0028] Implement the present invention under the conditions of alcohol-oil molar ratio 40 / 1, catalyst consumption 0.06%, reaction time 6min, reaction temperature 240 ℃, stirring intensity 400r / min, the influence of reaction pressure on biodiesel yield is shown in figure 2 . from figure 2 It can be seen that when methanol does not reach the supercritical state, the reaction is very slow, and the yield of biodiesel is very low. With the increase of pressure, methanol reaches the supercritical state, and the yield of biodiesel increases rapidly. When the pressure reaches 10MPa, As the pressure increases, the yield of biodiesel does not increase significantly, and the reaction pressure is too high, the color of biodiesel will deepen, and it will also increase equipment investment, energy consumption and equipment maintenance costs, and also increase unsafe factors. Therefore, this st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com