Catalytic cracking fractionating tower oil gas energy-saving apparatus and operation technique

An energy-saving device and catalytic cracking technology, applied in the petroleum industry, recovery of liquid hydrocarbon mixtures, etc., can solve the problems of consumption of cooling water, electricity and other public works, low-temperature heat sources can not be effectively used, etc., to achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

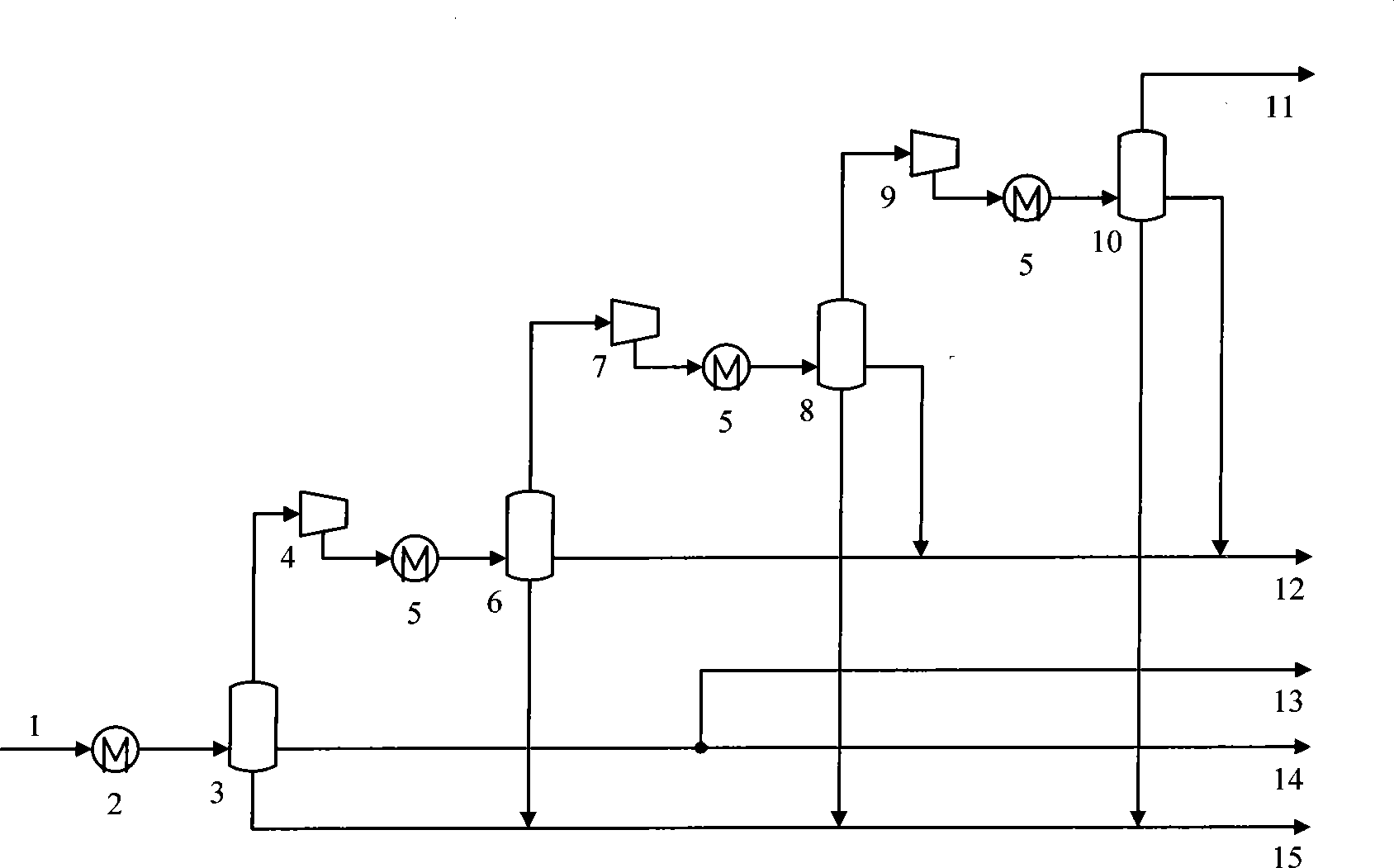

[0023] Example 1: A new technology for the recovery of low-temperature heat and energy-saving energy in the three-stage compression system of the oil-gas air compressor at the top of the fractionation tower of the catalytic cracking unit, such as figure 2 The structure and connection method shown.

[0024] The oil vapor temperature at the outlet of the heat exchanger of each compression system is 70℃~96℃; the operating pressure of the public low pressure desorption tank is 0.2MPa~0.4Mpa; the gas pressure at the outlet of the air compressor is 0.4MPa~0.8MPa, 0.6MPa~1.1 respectively MPa and 1.3MPa~1.7MPa.

[0025] Taking a refinery with a catalytic processing capacity of 0.4Mt / a as an example for simulation, the flow rate of oil and gas (1) at the top of the main fractionating tower is 50000kg / h and the temperature is 110℃. The top oil and gas (1) flowing out from the top of the main fractionation tower will enter the gas-liquid balance tank (3) for liquid separation after recoveri...

Embodiment 2

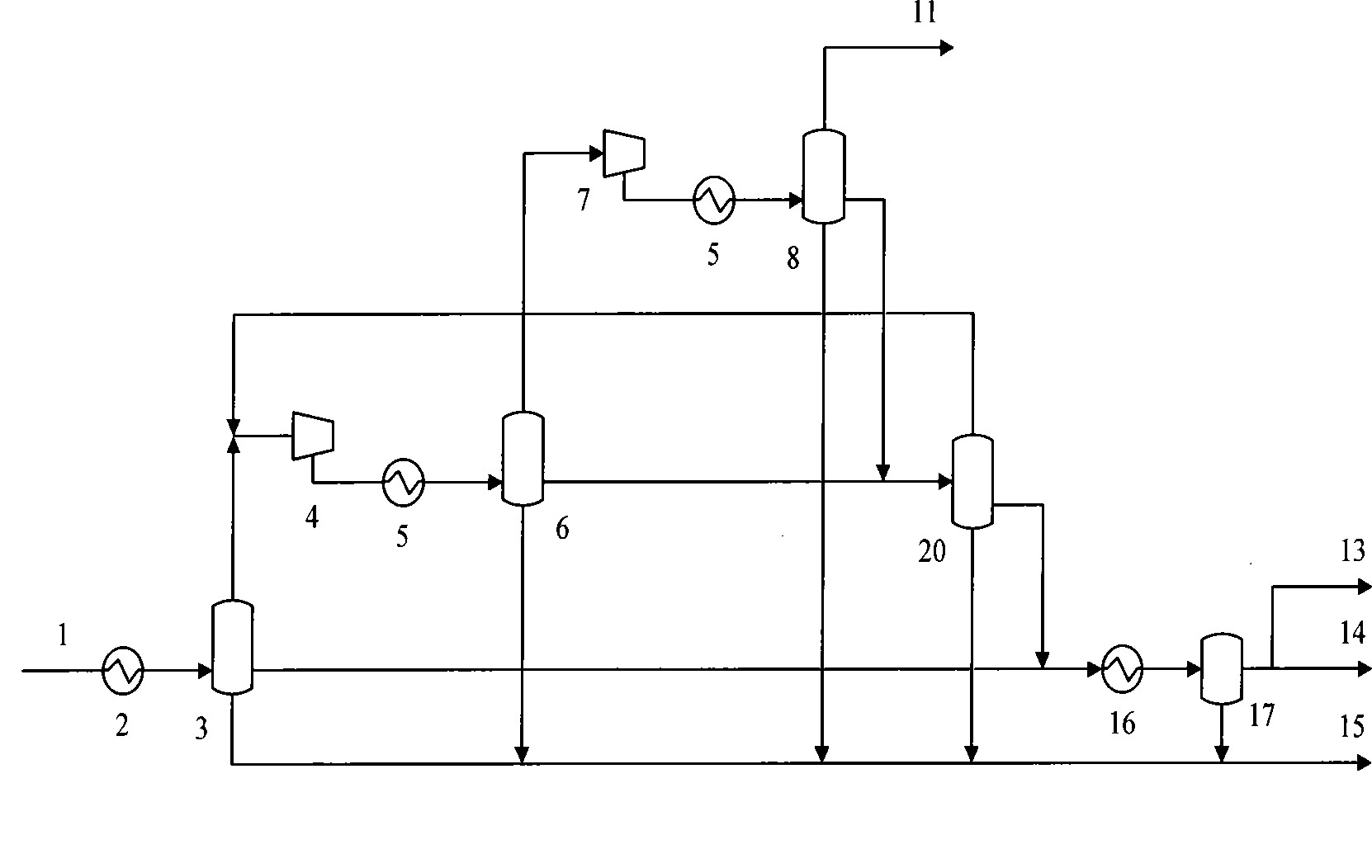

[0026] Example 2: A new technology for recovering low-temperature heat and energy-saving energy in the two-stage compression system of an oil-gas air compressor at the top of the fractionation tower of a catalytic cracking unit, such as image 3 The structure and connection method shown.

[0027] The temperature of the oil vapor at the outlet of the heat exchanger of each stage of the compression system is 70℃~96℃; the operating pressure of the public low pressure desorption tank is 0.2MPa~0.4Mpa; the gas pressure at the outlet of the air compressor is 0.4MPa~0.9MPa and 0.8MPa~1.7 respectively MPa.

[0028] On the basis of embodiment 2, the three-stage air pressure machine (9), the heat exchanger (2) and the three-stage gas-liquid balance tank (10) are eliminated, and the gas phase at the outlet of the first-level gas-liquid balance tank (6) directly enters the second air pressure machine ( 7). The gas pressure at the outlet of the air compressor is 0.7MPa and 1.5MPa, respectively...

Embodiment 3

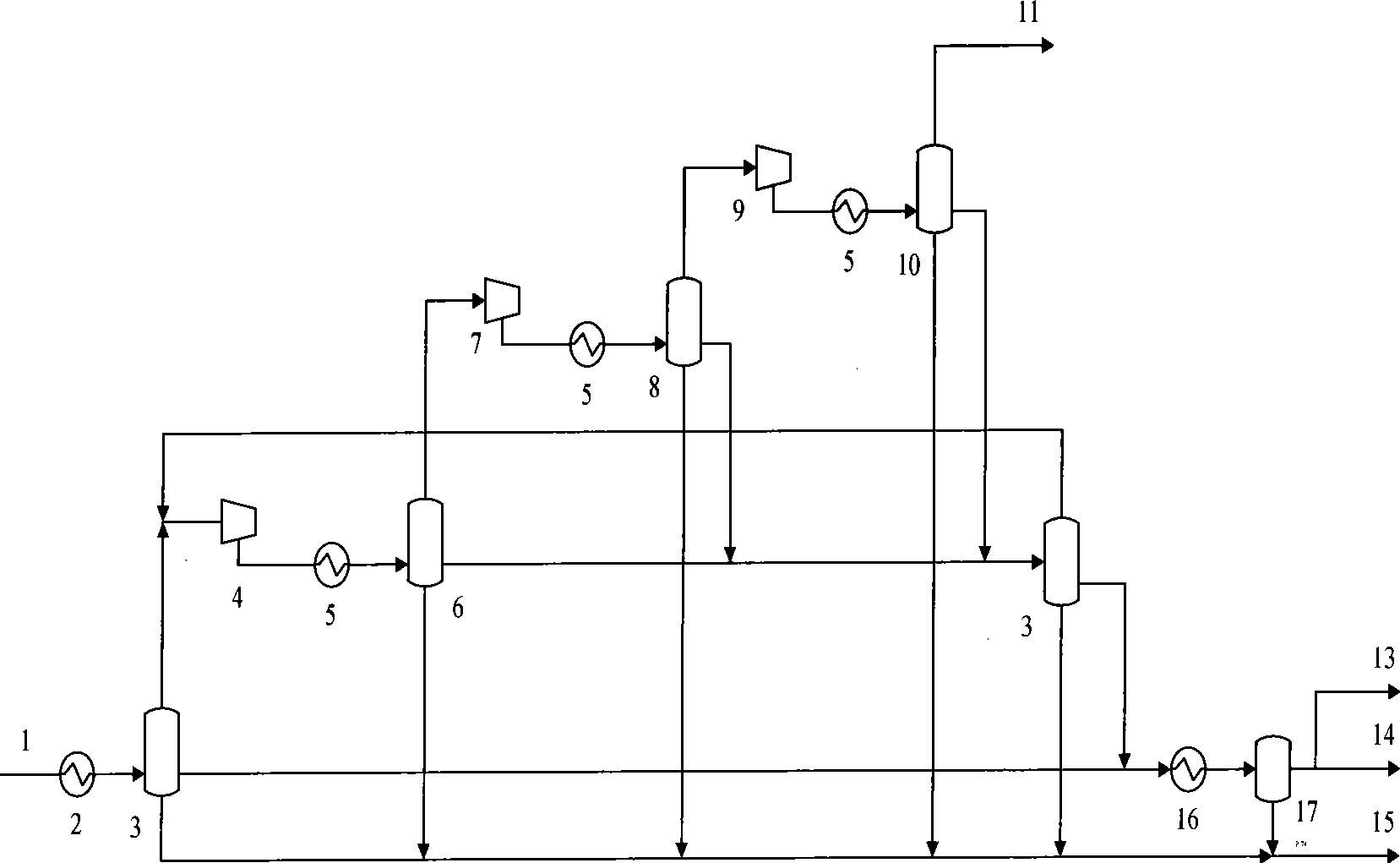

[0028] On the basis of embodiment 2, the three-stage air pressure machine (9), the heat exchanger (2) and the three-stage gas-liquid balance tank (10) are eliminated, and the gas phase at the outlet of the first-level gas-liquid balance tank (6) directly enters the second air pressure machine ( 7). The gas pressure at the outlet of the air compressor is 0.7MPa and 1.5MPa, respectively, the outlet temperature of the heat stream of the low-temperature heat extractor is 80°C, and the low-pressure desorption operating pressure of the common low-pressure desorption tank is 0.3MPa. Example 3: The new technology of low-temperature heat recovery and energy saving in the four-stage compression system of the top oil-gas air compressor of the fractionation tower of the catalytic cracking unit, such as Figure 4 The structure and connection method shown.

[0029] The temperature of the oil vapor at the outlet of the heat exchanger of each compression system is 70℃~96℃; the operating pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com