Method for improving survival ratio of lactobacillus after freeze drying by liquid nitrogen prefreezing

A technology of lactic acid bacteria and survival rate, applied in the field of pre-freezing to improve the survival rate of lactic acid bacteria after freeze-drying, can solve the problems of cell membrane and organelle damage, solute damage, high solute concentration, etc., achieve strong industrial implementation, prevent material foaming, pre-freeze Freezing Method Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

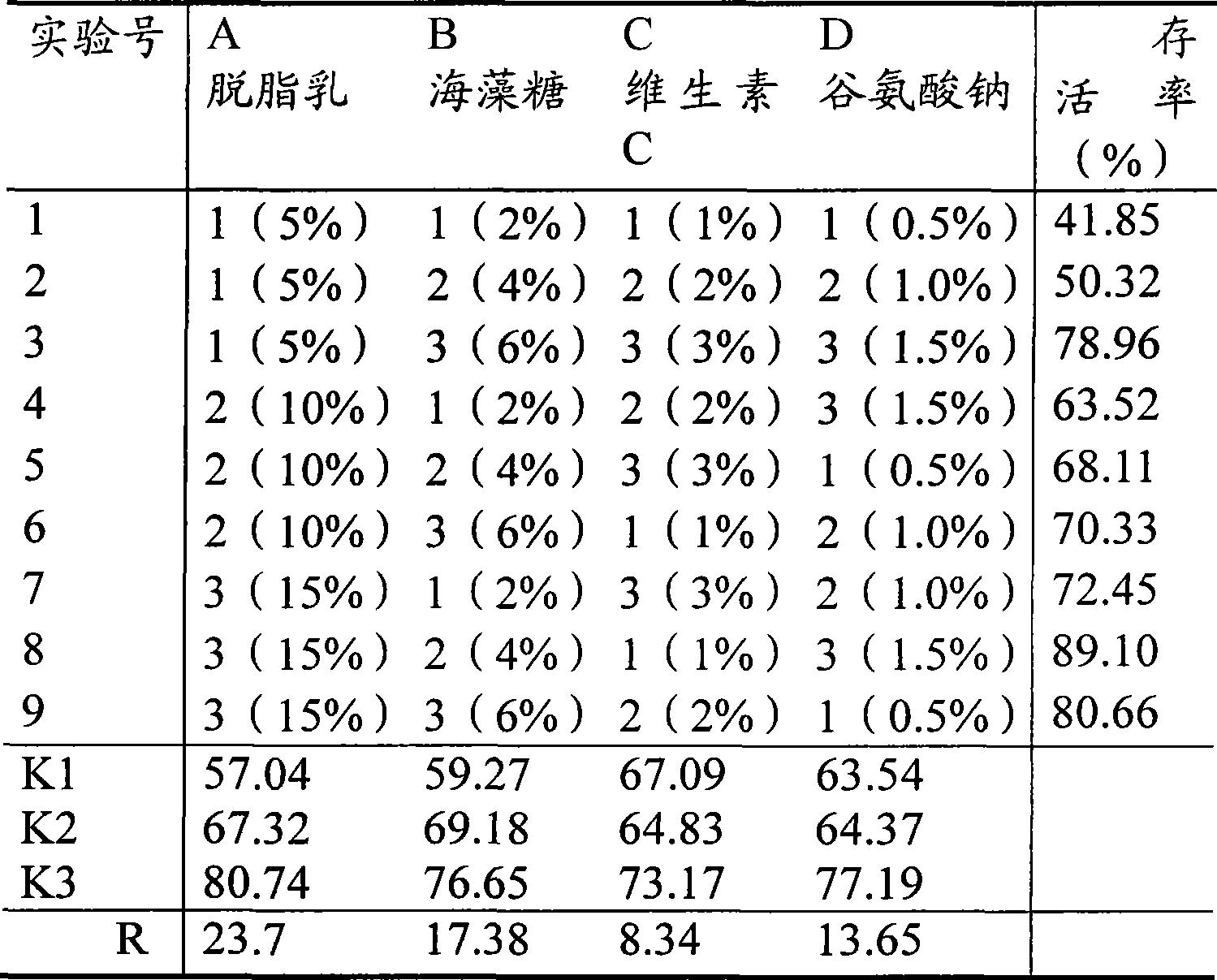

Method used

Image

Examples

Embodiment 1

[0025] Centrifuge 1000ml of Lactobacillus acidophilus bacteria solution at a speed of 6000r / min and a temperature of 4°C for 20min, discard the supernatant, wash with physiological saline and collect the bacteria sludge. In the bacteria sludge obtained by centrifugation, add the compound protective agent of twice the volume of the bacteria sludge, in the protective agent, skim milk: trehalose: vitamin C: sodium glutamate (mass ratio) = 15:4:1:1.5, and mix uniform.

[0026] Take a 500ml beaker, fill it with 15ml of bacteria slime, put it into a vacuum freeze dryer for pre-freezing, the pre-freezing temperature is -80°C, and the time is 2h.

[0027] Take four 500ml beakers, fill them with liquid nitrogen, quickly use 5ml, 1ml, 200μl, and 100μl pipette guns to drop 15ml of bacteria sludge into the four beakers respectively, and place them in the liquid nitrogen environment for 2 hours, then put Freeze dry in a freeze dryer.

[0028] To measure the number of viable bacteria in t...

Embodiment 2

[0030] Centrifuge 1000ml of Lactobacillus bulgaricus liquid at a speed of 4000r / min for 20min, discard the supernatant, wash with normal saline and collect the sludge. Add the same volume of the compound protective agent of Example 1 to the bacteria sludge obtained by centrifugation, and mix well.

[0031] Take a 500ml beaker, fill it with 15ml mixed sludge, put it into a vacuum freeze dryer for pre-freezing, the pre-freezing temperature is -80°C, and the time is 2h.

[0032] Take a 500ml beaker, fill it with liquid nitrogen, quickly drop 15ml of bacterial solution into the beaker with a 200μl pipette gun, place it in the liquid nitrogen environment for 1 hour, and then freeze it in a freeze dryer.

[0033] To measure the number of viable bacteria in the freeze-dried bacterial powder, add 10ml of normal saline to the bacterial powder, dilute it step by step, and then spread it on a flat plate to count the number of viable bacteria. After ordinary freeze-drying, the number of ...

Embodiment 3

[0035] Centrifuge 1000ml of Streptococcus thermophilus bacterial liquid at a speed of 6000r / min for 20min, discard the supernatant, wash with normal saline and collect the sludge. Add the same volume of the compound protective agent of Example 1 to the bacteria sludge obtained by centrifugation, and mix well.

[0036] Take a 500ml beaker, fill it with 15ml mixed sludge, put it into a vacuum freeze dryer for pre-freezing, the pre-freezing temperature is -80°C, and the time is 2h.

[0037] Take a 500ml beaker, fill it with liquid nitrogen, quickly drop 15ml of bacterial solution into the beaker with a pipette gun with a 100μl tip, place it in the liquid nitrogen environment for 1 hour, and then freeze it in a freeze dryer.

[0038] To measure the number of viable bacteria in the freeze-dried bacterial powder, add 10ml of normal saline to the bacterial powder, dilute it step by step, and then spread it on a flat plate to count the number of viable bacteria. After ordinary freeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com