Anode system for electrophoretic painting cathode

A cathodic electrophoresis and anode technology, used in electrolytic coatings, electrophoretic plating, coatings, etc., can solve problems such as high operating costs and environmental pollution, and achieve the effects of good current dispersion, saving anode materials, and reducing discharge area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

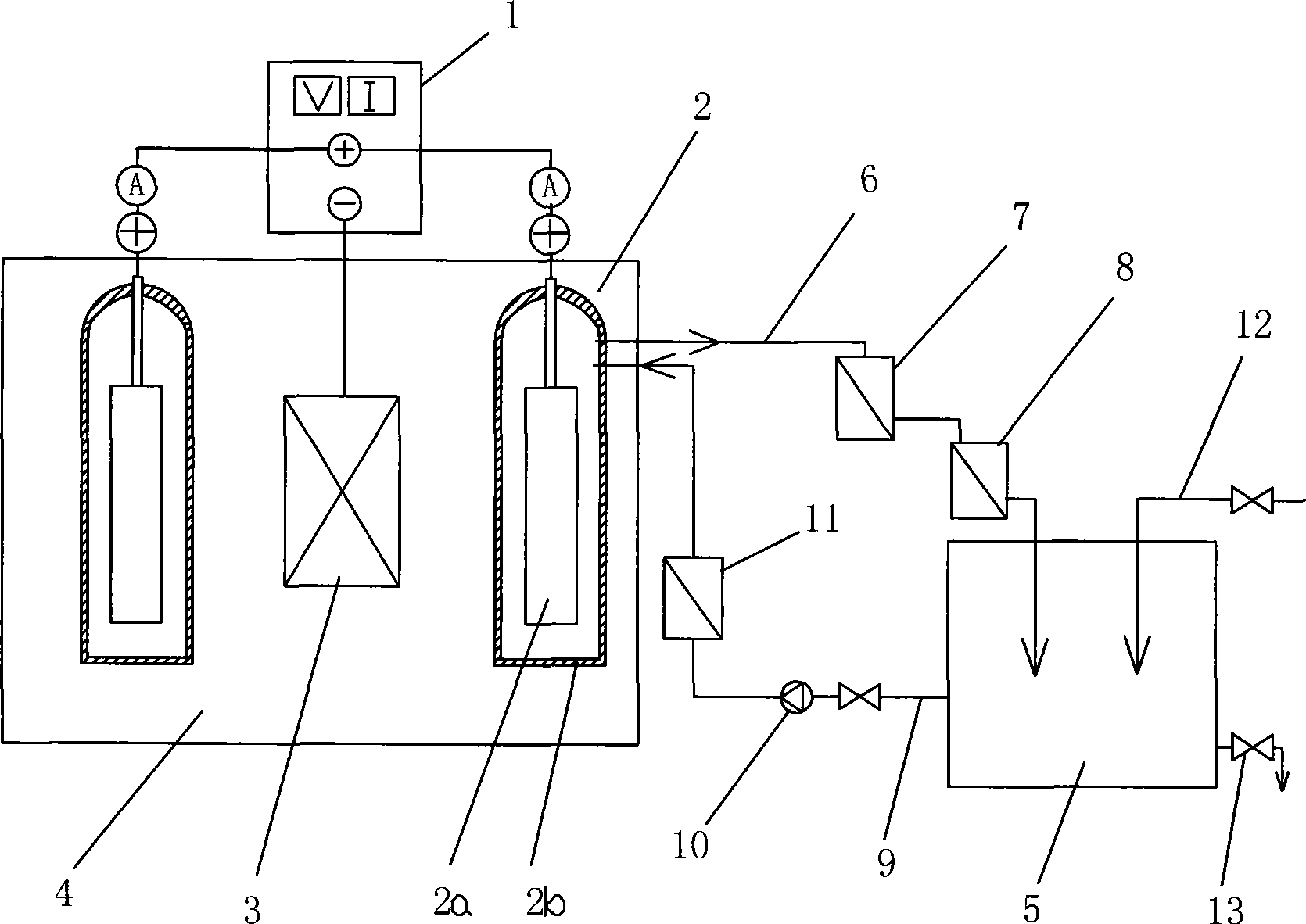

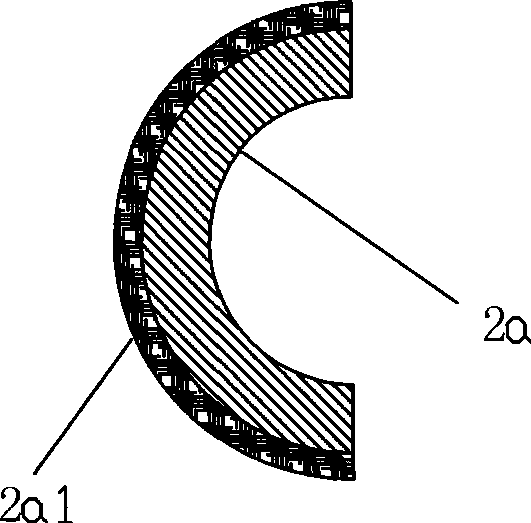

[0019] like figure 1 , figure 2 As shown, the anode system for cathodic electrophoretic coating includes power supply 1, anode device 2, metal workpiece 3, electrophoresis tank 4 and anolyte storage tank 5, the cathode of power supply 1 is connected to metal workpiece 3, and the anode of power supply 1 is connected to anode Device 2, the anode device 2 includes an anode 2a and an anode cover 2b, the anode 2a is a semi-cylindrical titanium tube with a thickness of 1.0 mm, and the outer surface of the semi-cylindrical titanium tube is electroplated with a platinum oxide coating 2a1 with a thickness of 10 μm; the anode 2a Placed in the anode cover 2b, there is a distance of 50mm between the anode 2a and the anode cover 2b, and the anode cover 2b is covered with a layer of polyethylene heterogeneous anion exchange membrane as the anode diaphragm. The anode cover 2b is filled with an acetic acid solution with a pH value of 2, and the anode cover is provided with an anode liquid o...

Embodiment 2

[0022] like figure 1 , figure 2 As shown, the anode system for cathodic electrophoretic coating includes power supply 1, anode device 2, metal workpiece 3, electrophoresis tank 4 and anolyte storage tank 5, the cathode of power supply 1 is connected to metal workpiece 3, and the anode of power supply 1 is connected to anode Device 2, the anode device 2 includes an anode 2a and an anode cover 2b, the anode 2a is a semi-cylindrical titanium tube with a thickness of 1.5mm, and the outer surface of the semi-cylindrical titanium tube is electroplated with a ruthenium oxide coating 2a1 with a thickness of 15 μm; the anode 2a Placed in the anode cover 2b, there is a distance of 100mm between the anode 2a and the anode cover 2b, and the anode cover 2b is covered with a layer of polyethylene heterogeneous anion exchange membrane as the anode diaphragm. The anode cover 2b is filled with a lactic acid solution with a pH value of 5, and the anode cover is provided with an anode liquid o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com