Method and apparatus for producing propylene

A propylene and reactor technology, which is applied in the field of propylene preparation and propylene preparation equipment, can solve the problems of catalyst degradation acceleration, catalyst deactivation, etc., and achieve the effects of reduced filling volume, prolonged regeneration cycle, and reduced equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

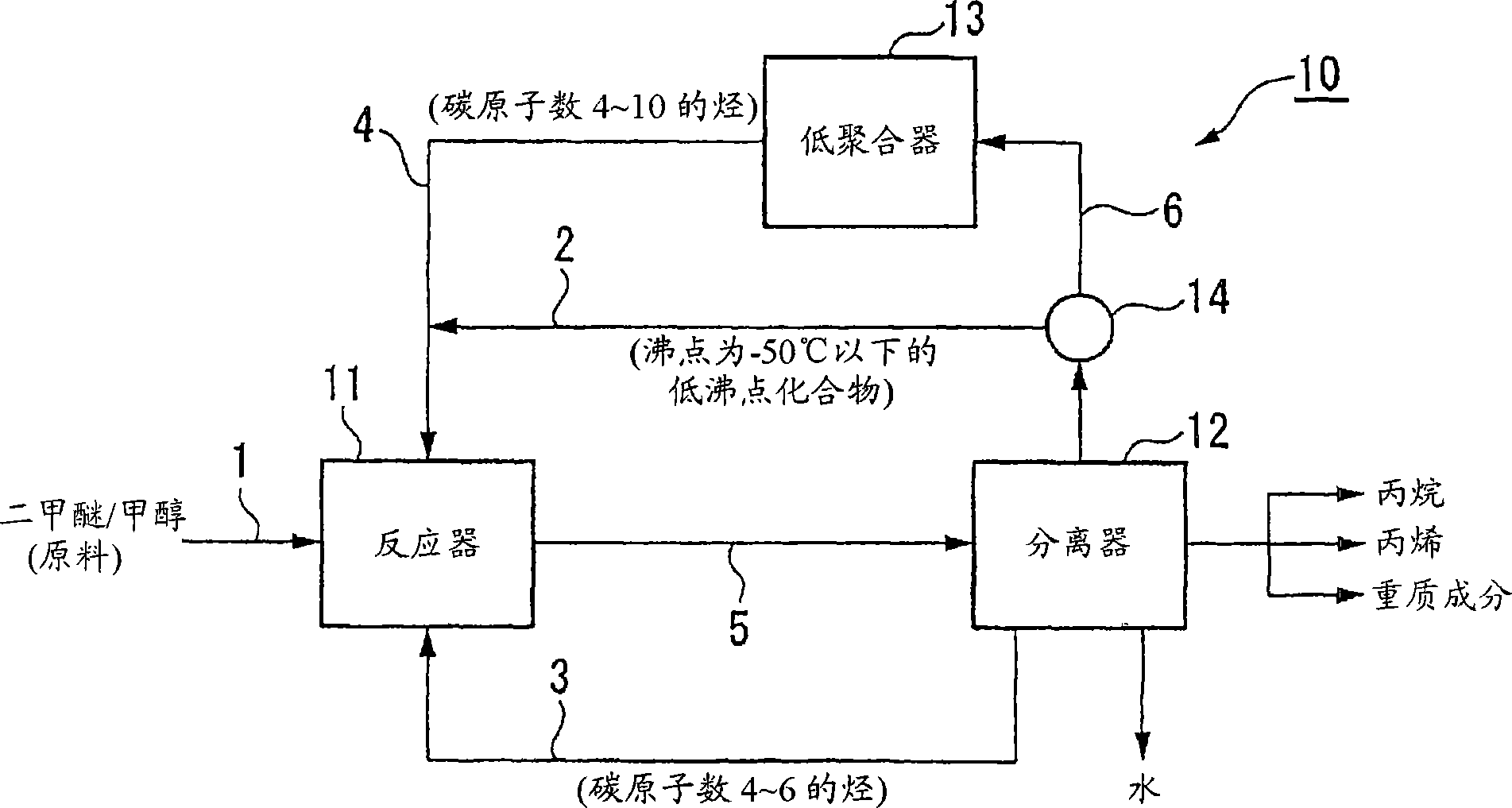

[0030] figure 1 It is an explanatory diagram showing the outline of the production apparatus for propylene of the present invention and the flow of the production method using the production apparatus.

[0031] In this embodiment, the production apparatus 10 of propylene has a reactor 11 , a separator 12 and an oligomerizer 13 . The reactor 11 is filled with a catalyst, and the raw material dimethyl ether / methanol, the low boiling point compound having a boiling point below -50°C and the hydrocarbons with 4 to 6 carbon atoms, which are refluxed from the separator 12 described later, are oligomerized The hydrocarbons having 4 to 10 carbon atoms supplied from the vessel 13 react to produce a reaction product containing propylene.

[0032] In the separator 12, the reaction product containing propylene obtained in the reactor 11 is separated and purified, and propylene, propane, heavy components, water, low-boiling compounds with a boiling point below -50°C, and carbon atoms are ...

Embodiment 1

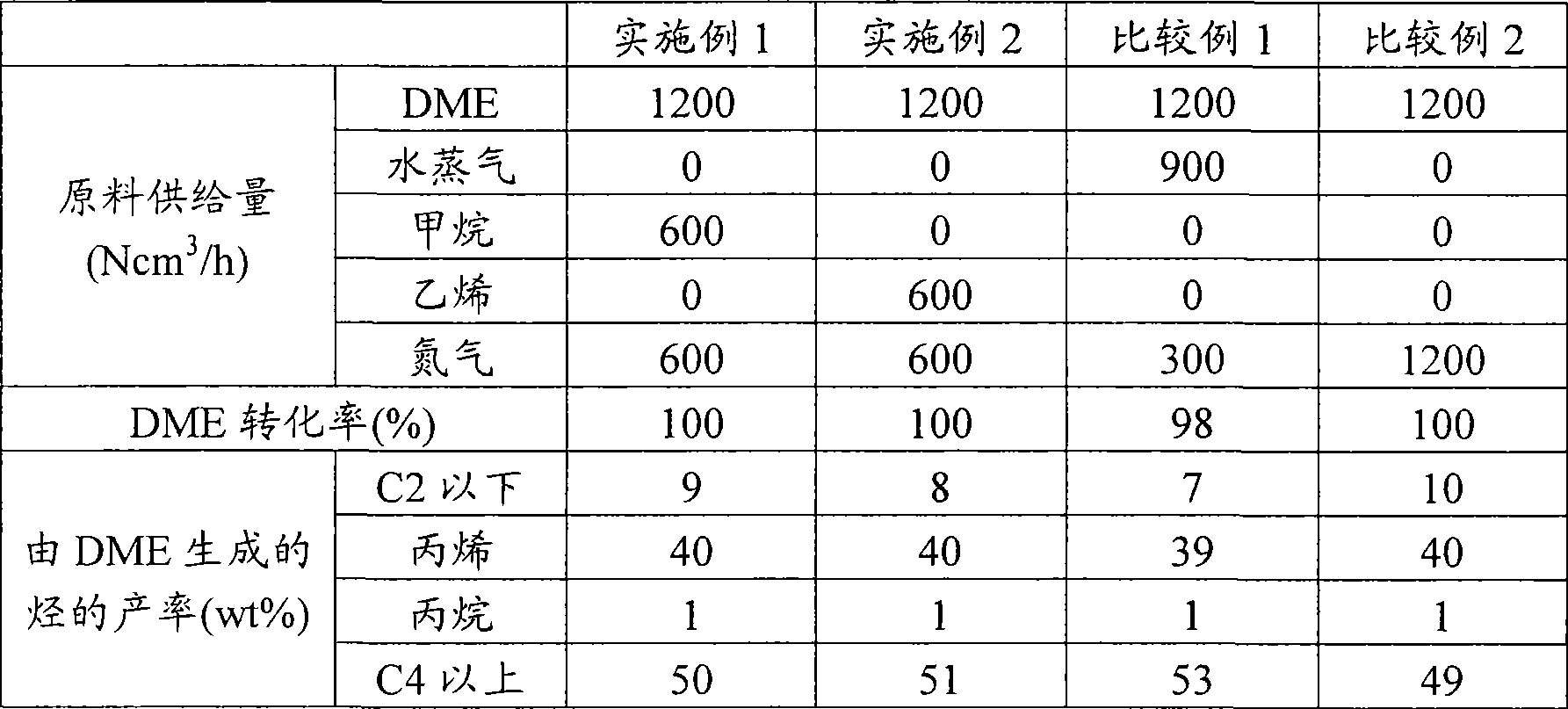

[0057] Mixed dimethyl ether (flow rate is 1200Ncm 3 / hour), methane (flow rate is 600Ncm 3 / hour), nitrogen (flow rate is 600Ncm 3 / hour), and the mixed gas is sent to the constant temperature reactor filled with HCaMFI catalyst, and it is reacted at a temperature of 530° C. under normal pressure. The weight hourly space velocity (WHSV), which is the feed amount ratio of the raw material dimethyl ether (DME) to the catalyst, was set to 9.6 g-DME / (g-catalyst·hour). Then, the yields and conversions of hydrocarbons having 2 or less carbon atoms, propylene, propane, and hydrocarbons having 4 or more carbon atoms relative to the total amount of dimethyl ether (DME) supplied were measured.

Embodiment 2

[0059] Mixed dimethyl ether (flow rate is 1200Ncm 3 / hour), ethylene (flow rate is 600Ncm 3 / hour), nitrogen (flow rate is 600Ncm 3 / hour), and the mixed gas is sent to the constant temperature reactor filled with HCaMFI catalyst, and it is reacted at a temperature of 530° C. under normal pressure. The weight hourly space velocity (WHSV), which is the feed amount ratio of the raw material dimethyl ether (DME) to the catalyst, was set to 9.6 g-DME / (g-catalyst·hour). Then, the yields and conversions of hydrocarbons having 2 or less carbon atoms, propylene, propane, and hydrocarbons having 4 or more carbon atoms relative to the total amount of dimethyl ether (DME) supplied were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com