Liquid composition capable of removing sulfide in gas

A liquid composition and degassing technology, which is applied in combustible gas purification, combustible gas purification/transformation, organic chemistry, etc., can solve problems such as lack of anti-corrosion ability, impact on desulfurization efficiency, and inability to obtain easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

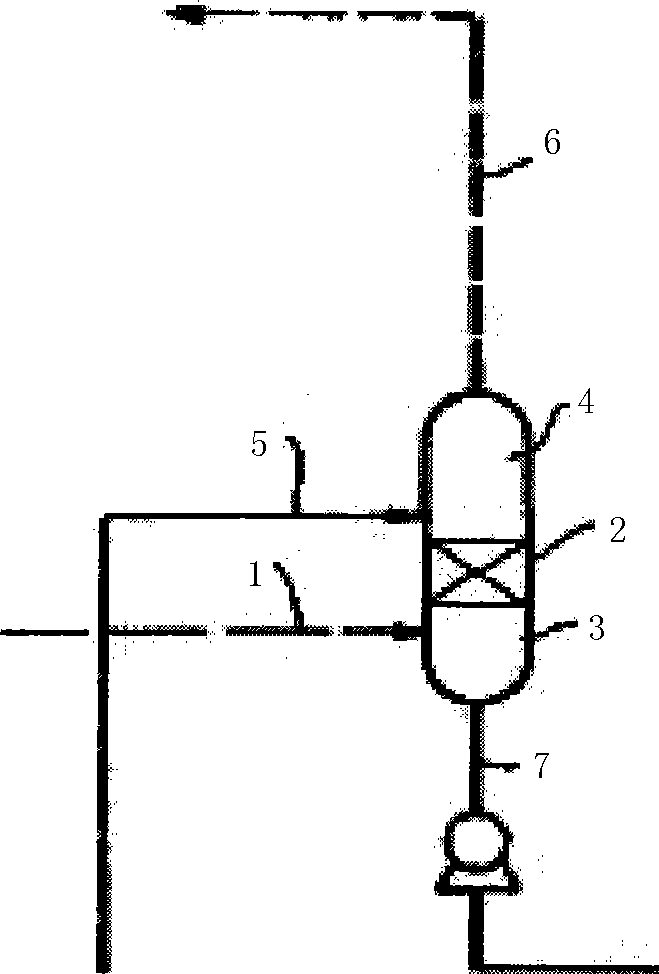

Image

Examples

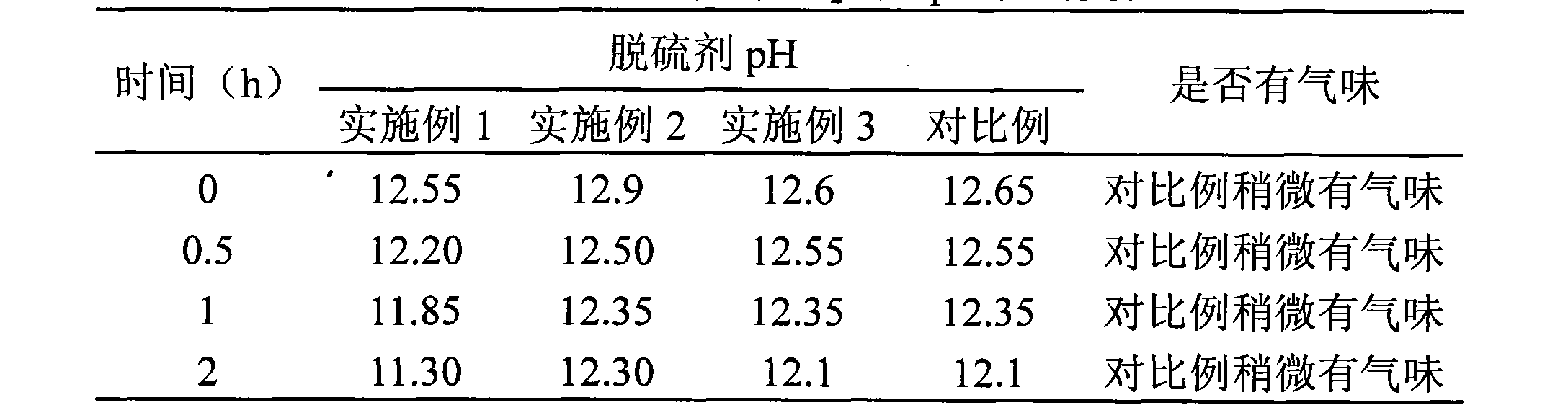

Embodiment 1

[0032] Composition of desulfurizer solution: hindered amine TBEE 10%, alkanolamine MDEA 45%; additives 44.9% (including benzotriazole 1%, polyoxyethylene sorbitan monooleate 4%, quinone 95%); defoamer methyl silicone oil 0.1%.

[0033] The solutions of the above components are mixed to prepare the desulfurizing agent solution of the present invention.

[0034] At 40°C under normal pressure, use the desulfurizer solution obtained above to pass figure 1 The device shown removes the gas to be treated (N 2 80%, CO 2 16%, H 2 S3%, mercaptan 540mg / m 3 ), the result H2 S, mercaptan removal rate is 90%.

Embodiment 2

[0040] Absorbing solution composition: hindered amine TBEE 20%, alkanolamine triisopropanolamine 35%; additives 44.9% (of which benzotriazole 3%, quinone 60%, α-naphthoquinone 37%); Defoamer methyl silicone oil 0.1%.

[0041] The preparation method and desulfurization method are the same as in Example 1.

[0042] The result shows H 2 S, mercaptan removal rate is 85%.

Embodiment 3

[0044] Composition of desulfurizer solution: hindered amine TBEE 10%, alkanolamine MDEA 30%, triisopropanolamine 15%; additives 44.9% (including polyoxyethylene sorbitan monooleate 10%, hydroquinone 90% %); antifoaming agent methyl silicone oil 0.1%.

[0045] The preparation method and desulfurization method are the same as in Example 1.

[0046] The result shows H 2 S, mercaptan removal rate is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com