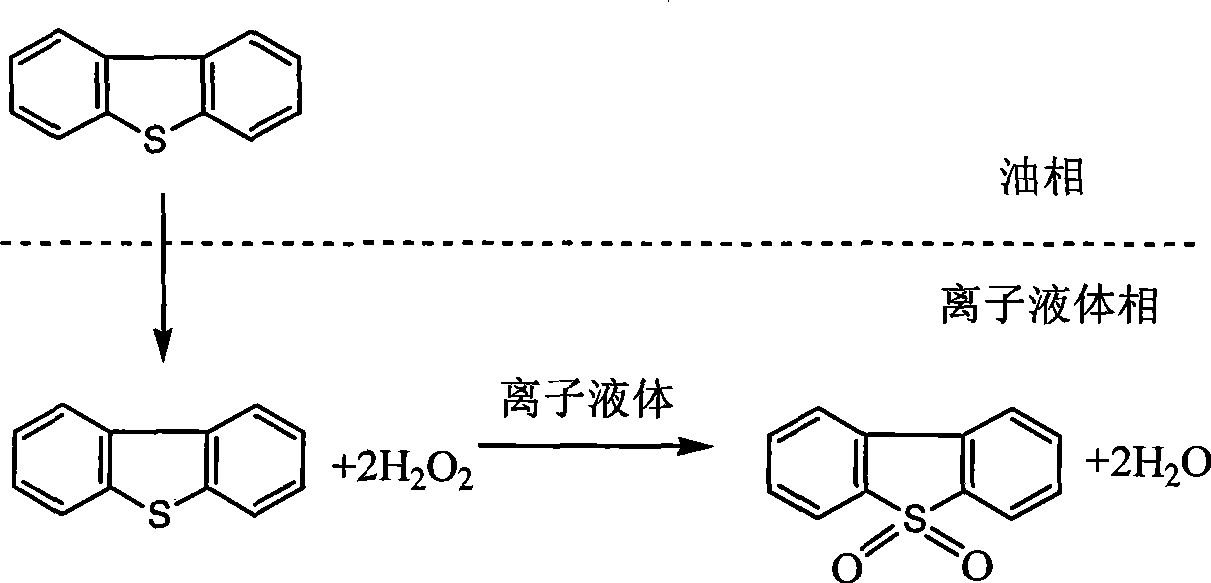

Abstraction-catalytic oxidation desulfurization method using FeCl3

A catalytic oxidation desulfurization, ionic liquid technology, applied in the direction of only multi-stage series refining process, etc., can solve the problems of consumption of acidic substances, low extraction desulfurization rate, long response time, etc., to achieve simple separation and high removal efficiency , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

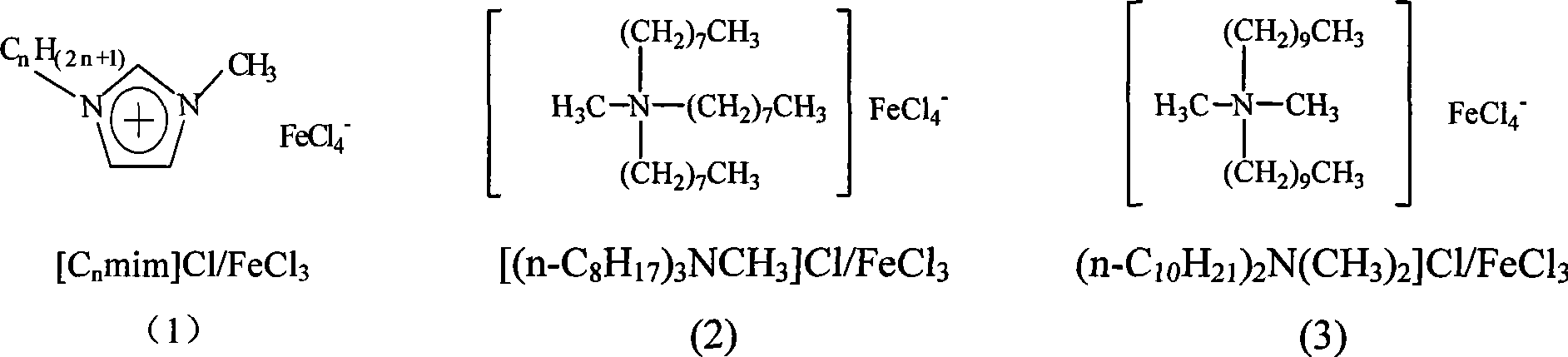

example 1

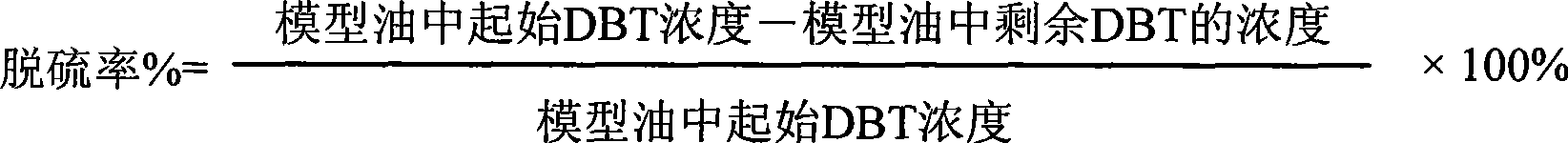

[0022] Example 1 In a reaction flask with magnetic stirring, add 0.867g of [C 4 mim]Cl / FeCl 3 Ionic liquid, at this time, the ionic liquid phase is in the lower layer, and the oil phase is in the upper layer; after magnetic stirring at 30°C for 5 minutes, the simulated oil is separated, and the removal rate of sulfur is 67.6% through detection and calculation.

example 2

[0023] Example 2 In a reaction flask with magnetic stirring, add 0.867g of [C 8 mim]Cl / FeCl 3The ionic liquid was magnetically stirred at 30°C for 30 minutes to separate the simulated oil, and the sulfur removal rate was calculated to be 71.5%.

example 3

[0024] Example 3 In a reaction flask with magnetic stirring, 0.867g of T was added to 2.6g (3.5mL) of simulated oil 8 Cl / FeCl 3 The ionic liquid was magnetically stirred at 50°C for 15 minutes to separate the simulated oil, and the sulfur removal rate was calculated to be 63.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com