A process for producing ε-polylysine by adsorption and immobilization fermentation

A technology of immobilized fermentation and polylysine, which is applied in the field of fermentation production of ε-polylysine and ε-polylysine by adsorption and immobilization fermentation, which can solve the problem of large oxygen consumption, limited oxygen transfer, unfavorable ε -PL efficient production and other issues to achieve high production efficiency, shorten batch production time, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

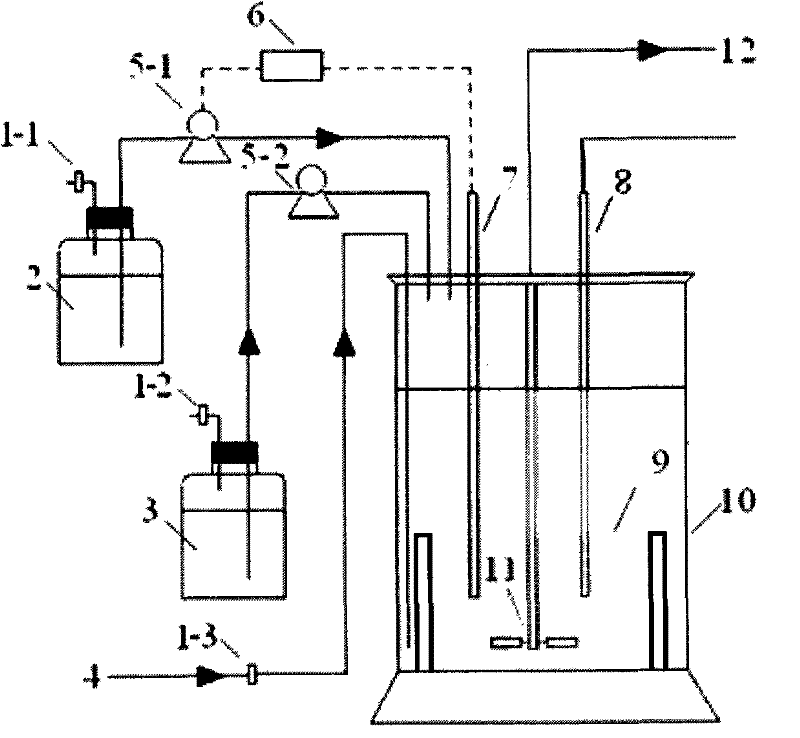

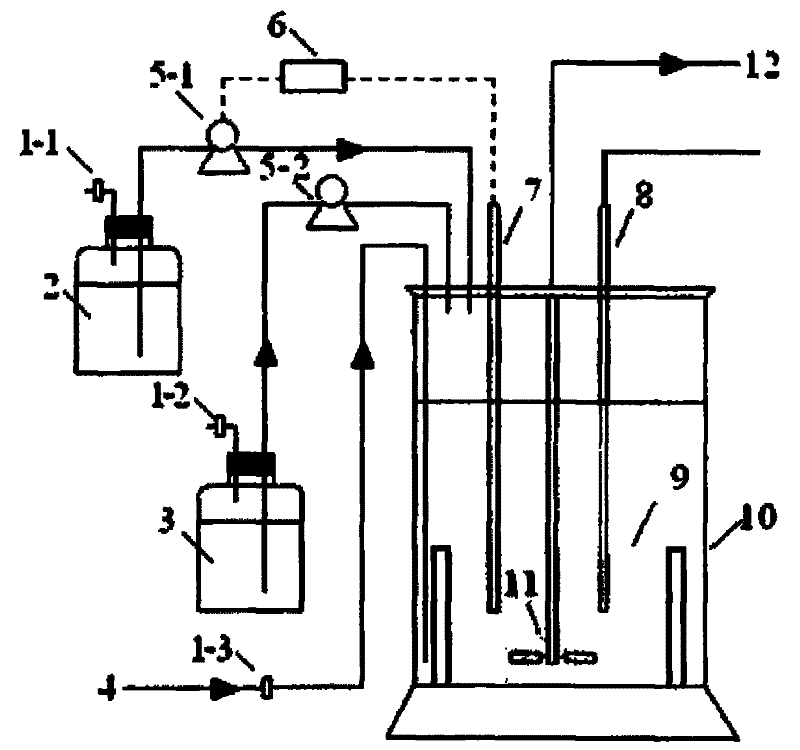

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of ε-PL by free cell fermentation (comparative example).

[0038] Using glucose as the carbon source, the laboratory has authorized the patented strain Bacillus militaris PL6-3 (Chinese invention patent: ZL2005100037774.2, strain preservation number: CCTCC No.M 205012) for free cell fermentation to produce ε-PL. Seed medium: glucose 10g / L, beef extract 5g / L, yeast extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O0.5g / L, utilize 6mol / L solution to adjust pH7.0. Fermentation medium: glucose 50g / L, yeast extract 5g / L, (NH 4 ) 2 SO 4 5g / L, Na 2 HPO 4 12H 2 O 1.58g / L, K 2 HPO 4 ·7H 2 O 0.82g / L, MgSO 4 ·7H 2 O 0.1g / L, use 6mol / L NaOH solution to adjust the pH to 7.0. Cultivate Lispora militaris PL6-3 at 28°C and 200r / min on a shaker for 24 hours, inoculate 300mL of seed solution with 10% (v / v) seed solution into 2.7L of sterilized fermentation culture culture medium, culture conditions: 28°C, 400r / min, ventilation rate 3L / min, the pH value o...

Embodiment 2

[0039] Example 2: Preparation of ε-PL by single-batch fermentation in an immobilized reactor.

[0040] Bacterial strain, seed culture medium, fermentation medium are with embodiment 1. Using reticular plant fiber gauze as the immobilization carrier, wrap the gauze with a length of 30 cm and a width of 15 cm in a circle along the pH electrode, temperature electrode, and sampling tube, and the stirring will not be affected after fixation. Fill the immobilization reactor with 2.7L seed medium and sterilize it. The seed liquid was cultured for 24 hours under the conditions of 30° C. and 250 r / min shaking table. Seed solution is inoculated in the immobilization reactor after sterilization by the inoculum amount (300mL) of 10% (v / v), culture condition: 30 ℃, 300r / min, ventilation rate 3.5L / min, utilize 8% ( The ammonia water of v / v) controls the pH value of the seed medium to 6.0, and cultivates for 15 hours to realize the immobilization of Lispora militaris PL6-3 on the mesh immo...

Embodiment 3

[0041] Example 3: Preparation of ε-PL by single-batch fermentation in an immobilized reactor.

[0042] Bacterial strain, seed culture medium, fermentation medium are with embodiment 1. Using the reticular plant fiber loofah towel as the immobilization carrier, fix the peeled and decimated loofah towel on the temperature electrode, the dissolved oxygen electrode, and the sampling tube respectively, and the stirring will not be affected after fixing. Fill the immobilization reactor with 2.55L seed culture medium and sterilize it. The seed solution was cultivated for 30 h at 32°C and 180 r / min on a shaker. Seed solution is inoculated in the immobilized reactor after sterilization by the inoculum amount (450mL) of 15% (v / v), culture condition: 32 ℃, 500r / min, ventilation rate 3.0L / min, utilize 15% ( The ammonia water of v / v) controls the pH value of the seed medium to 6.0, and cultures for 30 hours to realize the immobilization of Lispora militaris PL6-3 on the immobilized carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com